Active Member

|

[China]

Address: 3/F,BUILDING B ,YILAI INDUSTRIAL DISTRICT,BAI MANG,XILI TOWN,NANSHAN,SHENZHEN CHINA

Contact name:Jennie He

Shenzhen Strongd Model Technology Ltd. |

|

Clear PMMA Plastic Rapid Prototyping Polypropylene Injection Molding

Plastic injection mold standard process

1) Mold: materials for steel/aluminum

2) post-processing:

Mold:laser cutting,polishing,heat treatment on hardness

Product:100% clear transparent

3) test: tooling fixture, three coordinates testing.

Accuracy control:

Mold-Tolerance:+/-0.005mm

Plastic product:+/-0.1mm

Injection molding

Injection moulding (injection molding in the USA) is a manufacturing process for producing parts by injecting material into a mould. Injection moulding can be performed with a host of materials, including metals, glasses, elastomers, confections, and most commonly thermoplastic and thermosetting polymers. Material for the part is fed into a heated barrel, mixed, and forced into a mould cavity, where it cools and hardens to the configuration of the cavity.[1]:240 After a product is designed, usually by an industrial designer or an engineer, moulds are made by a mouldmaker (or toolmaker) from metal, usually either steel or aluminum, and precision-machined to form the features of the desired part. Injection moulding is widely used for manufacturing a variety of parts, from the smallest components to entire body panels of cars. Advances in 3D printing technology, using photopolymers which do not melt during the injection moulding of some lower temperature thermoplastics, can be used for some simple injection moulds.

Application

· Metal parts, fire test parts, fixture direct manufacturing and model demonstration test.

· Development of new products.

· Creative design and display of culture, creativity, clothing, household goods and other.

· Research and development of implants, teeth, skull repair, prosthetics and medical

equipment.

· Product design, rapid production of high-precision injection molds.

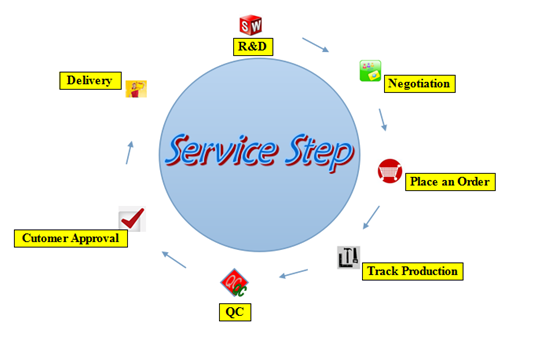

Service Step for a Project