Xi an Hi-Precision Machinery Co., Ltd. |

|

Verified Suppliers

|

|

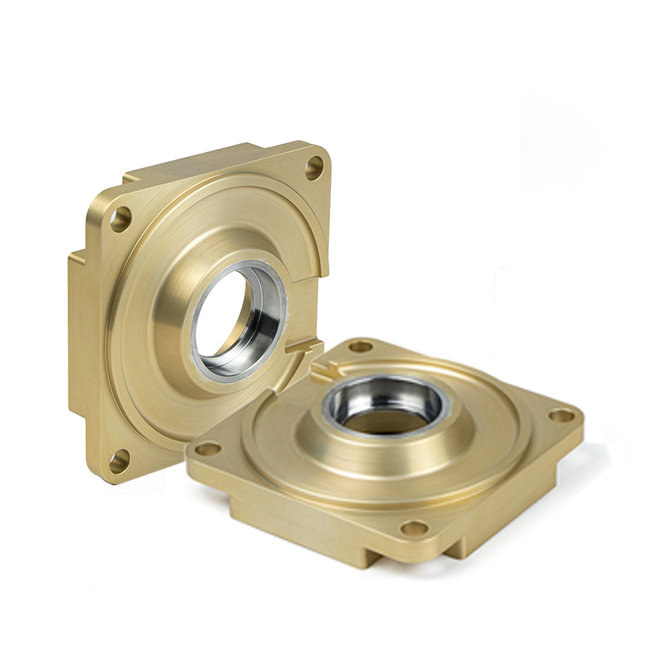

Application: Motor

Material: aluminum 6061

Surface Finished: Conductive Oxide yellow

Process: cnc milling, cnc turning

Tolerance:±0.01m~±0.05m

| Advantage | Competitive factory price and superior quality |

| Our service | Electronic and communication, Aerospace, Optical instrument,

Medical and pharmaceutical, |

| Equipments | CNC Machining Center, CNC Lathes, CNC Milling Machines, wire

cutting, laser cutting |

| Precision Processing | CNC machining, CNC milling and turning, laser cutting, drilling, grinding, bending, stamping, welding and so on |

| Drawing format | JPEG,PDF,DWG,DXF,IGS,STEP.CAD or according to your sample |

| Material | Stainless Steel, Brass, Aluminum, Steel, Carbon Steel, Titanium , plastic. Or other Exotic Alloys |

| Surface Finish | Anodize; Blacken, polishing, plating, sand blasting |

| Tolerance | +/- 0.002--0.5mm / can also be customized. |

| Inspection | 100% inspection before shipping |

| Payment Terms | 30%T/T in advance, the balance before delivery; Western Union is acceptable, the best pay us by Alibaba Assurance on line, that’s an assurance for overseas customers. |

Q: What is your company’s after service and warranty?

A: We make products according to drawings or samples strictly until

them reach your 100% satisfaction. We’ll be unconditional replace

the poor products once get the confirmation of defected products

within three months.

Q: How to place the order?

A:

1. You send us drawing or sample

2. The sample will be sent to you once finish

3. After the sample be confirmed, then you place an order and pay

us 50% deposit

4. We start to make the product

5. We take photos for your check and you then pay the balance

6. We arrange shipment

Q: Is it possible to know how the product is going on without

visiting your company?

A: We will offer a detailed products schedule and send weekly

reports with digital pictures and videos which show the machining

progress.

Q: How long can I expect to get the sample?

A: Samples will be ready for delivery in 7-15 days for new mold

products. The samples will be sent to you via express and arrive in

3-5 days. You can use your own express account or prepay us if you

do not have an account.

Q: What about the lead time for mass production?

A: It depends on the order quantity and processing technology. But

we always try to meet customers' requirement by adjusting our

workshop schedule. Generally, the lead time is about 15-35 days

Q: How is terms of delivery?

A: We accept EXW, FOB, CIF, etc. most convenient one is selectable

according to your demands.