Wuxi Lenge Purification Equipments Co., Ltd. |

|

Verified Suppliers

|

|

3100x2800x2570mm Sampling Booth Dispensing Booth After The Air Flow Is Treated By HEPA Filter

Weighing equipment

The weighing room distributes raw and auxiliary materials according to the process prescription. Only one kind of material is allowed to be weighed and prepared at the same time. In the weighing process, a large amount of dust will be produced, so pollution and cross pollution should be avoided to the greatest extent.

It is recommended to operate in an area equipped with a dust removal system to minimize the operator's exposure to the product.

At present, there is a relatively new dust removal method, which adopts local dust removal facilities. The system is equipped with primary, intermediate and high-efficiency filters, and operates in self circulation mode with vertical downward air outlet. This method can effectively control the dust from flying; all dust is collected on the primary effect filter bag, and the unified product is replaced regularly or according to the differential pressure indication, and different active ingredients are replaced Different filter bags can not only avoid cross pollution but also air pollution. For highly sensitized materials, it may be required to operate in a separate cabinet with half body or glove holes.

Cross contamination control through negative pressure environment option.

Full unidirectional airflow provides superior aseptic work zones.

GMP modular design with minimized joints and seams.

All components meet or exceed applicable safety requirements.

Technical Specifications & Parameters:

Material | SUS 304/316L stainless steel | ||||

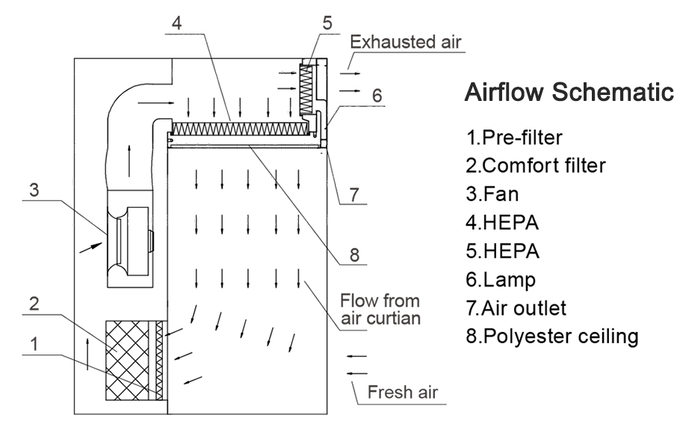

Filter Module | Pre-filter, comport filter, HEPA filter | ||||

Core Part | Air Blower | ||||

Model No. | LWR 13-120060 | LWR 34-150120 | LWR 75-200200 | LWR 112-300200 | LWR 186-400250 |

Outer Size | 1300×1200×2570 | 1600×1800×2570 | 2100×2800×2570 | 3100×2800×2570 | 4100×3300×2570 |

Inner Size | 1200×600×2000 | 1500×1200×2000 | 2000×2000×2000 | 3000×2000×2000 | 4000×2500×2000 |

Rated Air Velocity | 0.45±20% | ||||

Cleanliness Class | Same as the background area | ||||

Power Supply | 380V, 50Hz | ||||

Power (kW) | 0.8 | 2 | 4 | 4 | 7.5 |

Note: The specifications listed in above table are only for

customer’s reference. It is mostly designed and manufactured

according to customer’s URS.

Containment System:

Main Stream - The opening provides an airflow velocity of 0.45 m/s.

Includes electrical sockets as standard.

RH/Temperature sensor.

Emergency stop.

HEPA fan module provides laminar flow of particlefree air (measured at 0.3µm particles) to meet clean room requirements—99.995% efficient ULPA filters also available.

Filter Module

—— Pre filter -- Panel filter G4

—— Comfort filter -- Bag filter F8

—— HEPA filter -- Gel sealed mini-pleated HEPA filter H14

380 V power supply

Product Outline Design: