Shenzhen Bicheng Electronics Technology Co., Ltd |

|

High Frequency Hybrid PCB 4 Layer Mixed PCB Board Bulit On Rogers 12mil RO4003C and FR-4

(PCB’s are custom-made products, the picture and parameters shown are just for reference)

Hi Everyone,

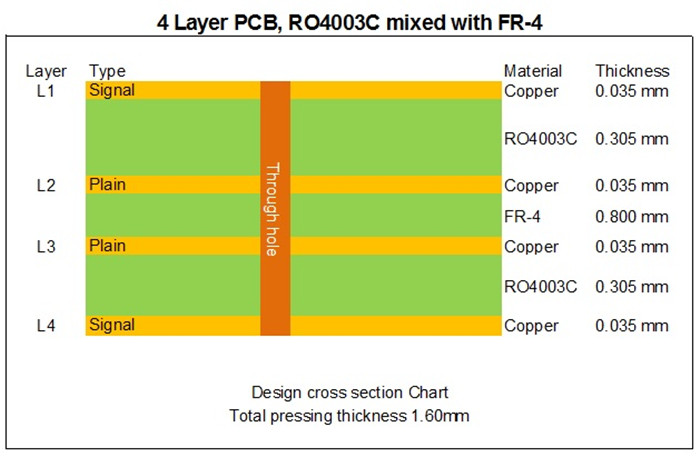

Today, we’re going to talk about 4-layer high frequency PCB made on 12mil RO4003C and FR-4 combined.

The board is designed as a 4-layer structure, because 4-layer PCB is relatively simple and inexpensive, which is helpful to open up a new market.

Let’s see today’s first board.

Viewing from stack up, we can see the 1st layer to the 2nd layer and 4th layer to 3rd layer are 12mil core of RO4003C, the core has fixed thickness which is very important to the electrical length of RF lines on the circuit board, and the rest are FR-4 materials. Copper weight on inner layer and outer layer is 1 ounce.

The 2nd board FR-4 is moved to layer 3 and layer 4. According to the actual applications, the thickness of dielectric material and FR-4 can be adjusted.

The applications of 12mil RO4003C hybrid PCB is wide, such as Modular oscilloscope, antenna combiner, balanced amplifier, 4G antenna etc.

The advantages of 12mil RO4003C hybrid PCB are reflected in following 3 points:

1) RO4003C exhibits a stable dielectric constant over a broad frequency range. This makes it an ideal substrate for broadband applications.

2) Reducing signal loss in high frequency application meets the development needs of communication technology.

3) Cost reduced over stack-ups with all low loss material;

At present, the mature mixed pressing materials are as follows:

RO4350B + FR4;

RO4003C + FR4;

F4B + FR4;

RT/duroid 5880 + RO4350B

RT/duroid 5880 + FR4

Our PCB Capability (Hybrid Design)

| PCB Type: | Hybrid PCB, Mixed PCB |

| Mixed type: | RO4350B + FR4; |

| RO4003C + FR4; | |

| F4B + FR4; | |

| Duroid/RT5880 + RO4350B | |

| Duroid/RT5880 + FR4 | |

| Solder mask: | Green, Red, Blue, Black, Yellow |

| Layer count: | 4 Layer, 6 Layer, Multilayer |

| Copper weight: | 0.5oz (17 µm), 1oz (35µm), 2oz (70µm) |

| PCB thickness: | 1.0-5.0mm |

| PCB size: | ≤400mm X 500mm |

| Surface finish: | Bare copper, HASL, ENIG, Immersion tin, OSP |

At the same time, we are able to supply blind via board, buried via board and HDI board. All the PCB's of our company will go through AOI test, open and short circuit test, solderability test and 288 ℃ thermal stress test to ensure high quality PCB shipped to your hands.

Thank you for your reading. You’re welcome to contact us for your RF PCB enquiries.

| RO4003C Typical Value | |||||

| Property | RO4003C | Direction | Units | Condition | Test Method |

| Dielectric Constant,εProcess | 3.38±0.05 | Z | 10 GHz/23℃ | IPC-TM-650 2.5.5.5 Clamped Stripline | |

| Dielectric Constant,εDesign | 3.55 | Z | 8 to 40 GHz | Differential Phase Length Method | |

| Dissipation Factortan,δ | 0.0027 0.0021 | Z | 10 GHz/23℃ 2.5 GHz/23℃ | IPC-TM-650 2.5.5.5 | |

| Thermal Coefficient of ε | +40 | Z | ppm/℃ | -50℃to 150℃ | IPC-TM-650 2.5.5.5 |

| Volume Resistivity | 1.7 x 1010 | MΩ.cm | COND A | IPC-TM-650 2.5.17.1 | |

| Surface Resistivity | 4.2 x 109 | MΩ | COND A | IPC-TM-650 2.5.17.1 | |

| Electrical Strength | 31.2(780) | Z | Kv/mm(v/mil) | 0.51mm(0.020") | IPC-TM-650 2.5.6.2 |

| Tensile Modulus | 19,650(2,850) 19,450(2,821) | X Y | MPa(ksi) | RT | ASTM D 638 |

| Tensile Strength | 139(20.2) 100(14.5) | X Y | MPa(ksi) | RT | ASTM D 638 |

| Flexural Strength | 276 (40) | MPa (kpsi) | IPC-TM-650 2.4.4 | ||

| Dimensional Stability | <0.3 | X,Y | mm/m (mil/inch) | after etch+E2/150℃ | IPC-TM-650 2.4.39A |

| Coefficient of Thermal Expansion | 11 14 46 | X Y Z | ppm/℃ | -55℃to288℃ | IPC-TM-650 2.4.41 |

| Tg | >280 | ℃ TMA | A | IPC-TM-650 2.4.24.3 | |

| Td | 425 | ℃ TGA | ASTM D 3850 | ||

| Thermal Conductivity | 0.71 | W/M/oK | 80℃ | ASTM C518 | |

| Moisture Absorption | 0.06 | % | 48hrs immersion 0.060" sample Temperature 50℃ | ASTM D 570 | |

| Density | 1.79 | gm/cm3 | 23℃ | ASTM D 792 | |

| Copper Peel Stength | 1.05 (6.0) | N/mm (pli) | after solder float 1 oz. EDC Foil | IPC-TM-650 2.4.8 | |

| Flammability | N/A | UL 94 | |||

| Lead-free Process Compatible | Yes | ||||