HUNAN CHARMHIGH ELECTROMECHANICAL EQUIPMENT CO., LTD. |

|

Verified Suppliers

|

|

ABOUT US

Hunan Charmhigh Electromechanical Equipment Co., Ltd is the

well-known manufacturer of high-end SMT equipment in China.

The company is located in the Changsha High-tech Development

Zone,covering a total area of 3600 square meters.

As a professional modern science and technology enterprise capable of both R&D,production and marketing, Charmhigh has been leading the way in SMT technology for more than ten years.

Different series of multi-head full-automatic SMT machines have been developed and manufactured by Charmhigh to meet various practical production needs.

In accordance with the business philosophy of "Customer First, Innovation Paramount", Charmhigh has won the hearts of thousands of customers all over the world.

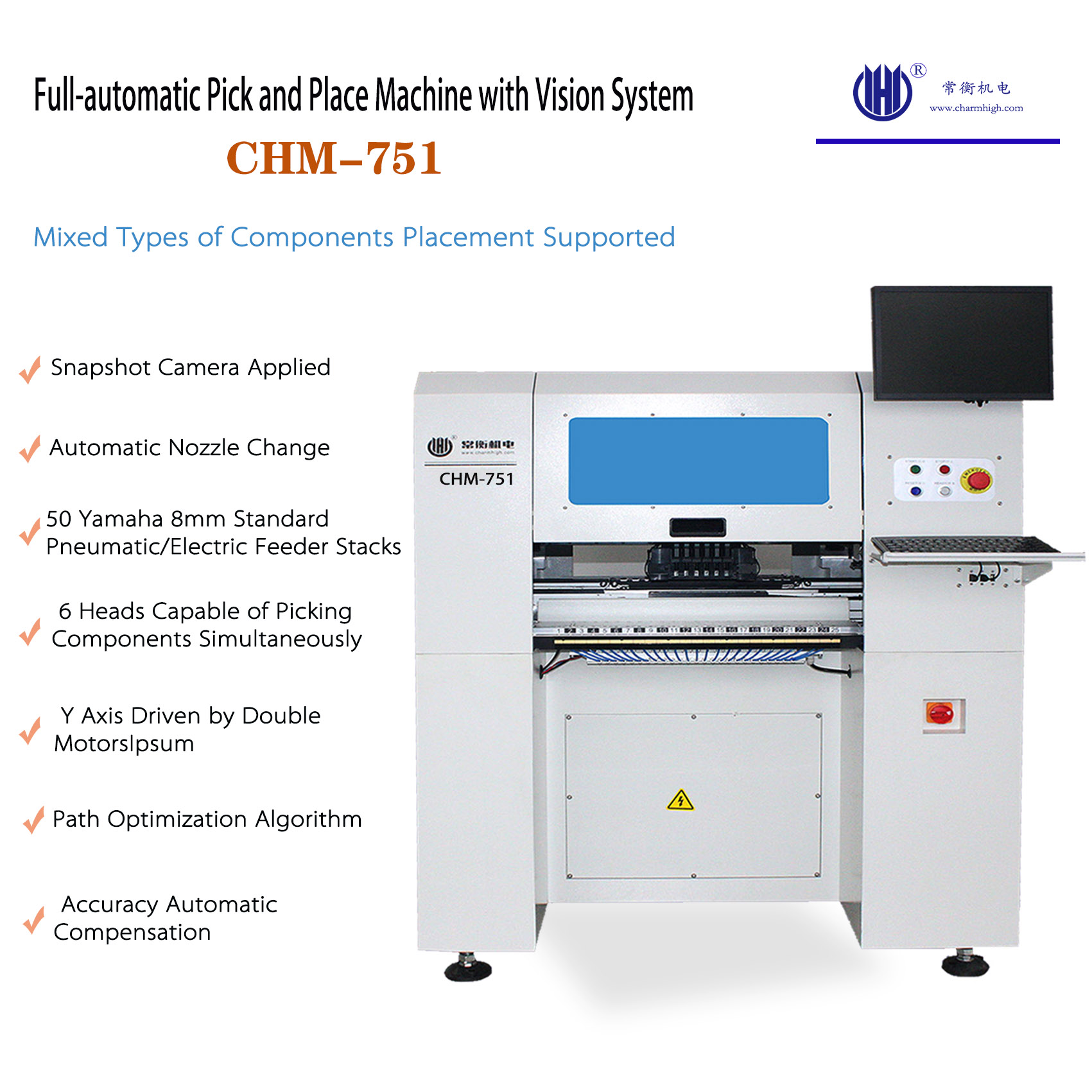

| CHM-751 Specifications | |

| Dimensions | 1280mm(L)×1190mm(W)×1470mm(H) |

| Weight | 540kg |

| Power Supply | AC220V (50Hz, single phase), 2.8kW |

| Air Supply | 0.5MPa ~0.7MPa |

| Vacuum Generation | Japan PISCO Vacuum generator |

| Mounting Head Quantity | 6 |

| Mounting Speed | 13000cph (optimal) |

| Mounting Accuracy | ±50μm@μ±3σ/chip |

| Control Accuracy | 5μm |

| Component Height | 12mm |

| Component Type | 0201/0402/0603~5050/SOT/SOP/QFP/QFN/BGA, etc. (resistor/capacitor/diode/triode/LED/IC, etc.) |

| PCB Thickness | 0.6mm~3.5mm |

| PCB Size | 400mm(L)×350mm(W) |

| PCB Conveying | 3-section-rail automatic conveying, PCB support |

| Nozzle Change | Automatic nozzle change (19-hole nozzle library) |

| Control System | Built-in industrial computer (Windows 7) equipped with monitor, keyboard, and mouse |

| Drive System | X&Y axis driven by servo motors (Y axis by double motors); adopting flexible S-curve acceleration and deceleration |

| Transmission System | Ground Ball screw + linear guide (Y axis with double screws) |

| Feeding System | 50 Yamaha 8mm standard pneumatic/electric feeder stacks (also suitable for IC tray and stick feeder) |

| Vision System | Snapshot camera×6 (component size applicable: 16mm×16mm); IC camera×1 (component size applicable: 36mm×36mm); Mark camera×2 |

Notes

1.Machines need keeping away from the humid environment and dust,

or which will get on electrical shock and fire.

2.Machines need lying stable platform, or which the shake may lead

to reduce the precision and even turn over and personal injury.

3.Don’t dismounting the machines casually, or the machine may be

broken.

4.Don’t touch the optical axis and the mounting head, or which may

damage the machine and hurt yourselves.

5.Make sure the machine engine accordance with the requirements of

the standard machine and make sure lie on the ground very well.

6.Make sure the machine away from the inflammables and explosives

to avoid the fire and getting the electric shock.

7.Take the small machine parts like suction nozzle at the place

where the babies can’t touch.

8.Don’t take the pulling needle stretch out for too long time, or

the pulling needle will be broken.

9.Don’t take the machine in the Sun or the highlight directly, or

which will reduce the machine precision and even broke the machine.

10.Please kindly contact us if any other questions.

Notes

1.Machines need keeping away from the humid environment and dust,

or which will get on electrical shock and fire.

2.Machines need lying stable platform, or which the shake may lead

to reduce the precision and even turn over and personal injury.

3.Don’t dismounting the machines casually, or the machine may be

broken.

4.Don’t touch the optical axis and the mounting head, or which may

damage the machine and hurt yourselves.

5.Make sure the machine engine accordance with the requirements of

the standard machine and make sure lie on the ground very well.

6.Make sure the machine away from the inflammables and explosives

to avoid the fire and getting the electric shock.

7.Take the small machine parts like suction nozzle at the place

where the babies can’t touch.

8.Don’t take the pulling needle stretch out for too long time, or

the pulling needle will be broken.

9.Don’t take the machine in the Sun or the highlight directly, or

which will reduce the machine precision and even broke the machine.

10.Please kindly contact us if any other questions.

Hunan Charmhigh Electromechanical Equipment Co., Ltd