HUNAN CHARMHIGH ELECTROMECHANICAL EQUIPMENT CO., LTD. |

|

Verified Suppliers

|

|

CHM-T48VB Pcb Smt Pick & Place Machine Pick And Place Led Equipment

We have units in stock ready for immediate delivery!

Shops seeking to increase their in-house capabilities with a full-featured PnP machine will achieve better schedule management and cost control using the T48VB. It is the one machine that delivers best-in-class Yearly-Yield for fast payback. The low cost places the T48VB within reach for shops of all sizes that do not require PnP machine integration with an automated line. If you’re seeking alternatives to outsourcing prototypes and short runs with affordable and easy-to-implement in-house operations, the T48VB is the one solution to keep you on schedule and on budget.

Proven Technology

The Charmhigh T48VB is an evolutionary product that is a direct

result of many years of experience building a wide variety of PnP

machines for the electronics industry, universities, research labs,

and creative shops. We have applied our deep knowledge of machine

design and production best practices to deliver the kinds of

features and performance that enable even the smallest shops to

take the step into in-house prototyping and small-batch

manufacturing.

| CHM-T48VB Specifications | |

| Dimensions | 1310mm(L)×710mm(W)×340mm(H) |

| Weight | 49kg |

| Power Supply | AC220V (50Hz, single phase) /AC110V (60Hz, single phase); 300W |

| Air Supply | No external air supply required |

| Vacuum Generation | Built-in vacuum pump |

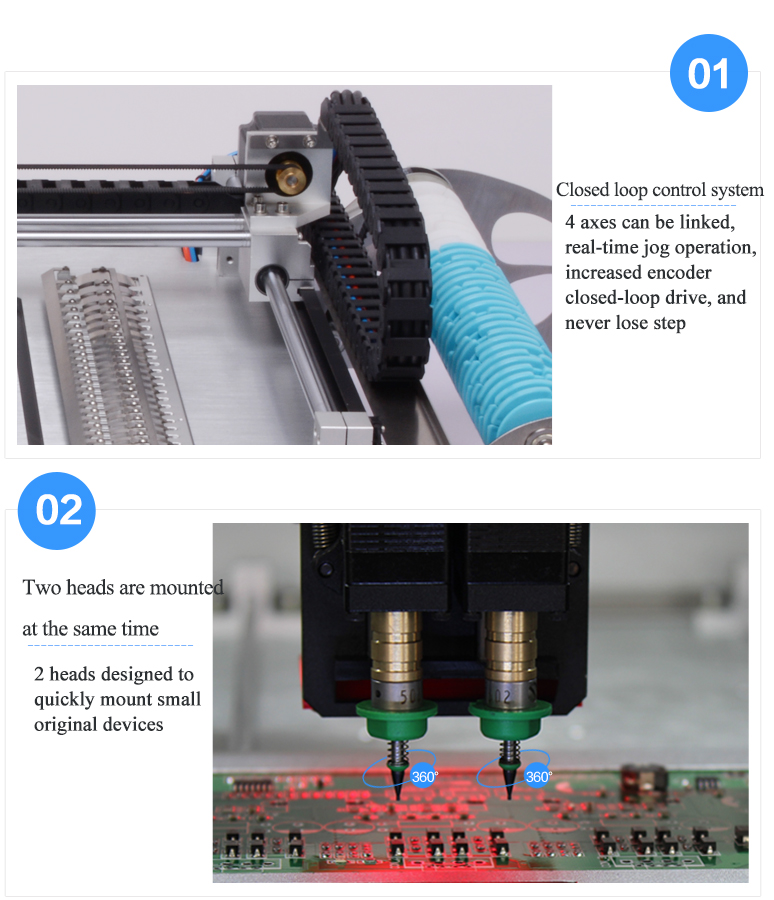

| Mounting Head Quantity | 2 |

| Mounting Speed | 6000cph(optimalwithout vision detection); 4000cph (optimal with vision detection) |

| Control Accuracy | 0.025mm |

| Component Type | 0402/0603~5050/SOT/SOP/QFP/QFN/BGA, etc. (resistor/capacitor/diode/triode/LED/IC, etc.) |

| PCB Thickness | 0.6mm~3.5mm |

| PCB Size | 10mm(L)×10mm(W)~345mm(L)×360mm(W) |

| PCB Conveying | Manual operation |

| Nozzle Change | Manual operation |

| Control System | Built-in computer(embedded Linux operating system), 7-inch touch screen |

| Drive System | X&Y-axisdriven by stepping motors in the way of closed-loop control realized by encoder; Z-axis capable of reset detection;all motors adopting flexible S-curve acceleration and deceleration; tape puller automatic reset supported |

| Transmission System | Synchronous belt + polished rod +linear guide |

| Feeding System | 58 tape feeding stacks(8mm:44,12mm:8;16mm:4,24mm:2;customization supported), 14 preset general IC stacks, worksurface custom IC trays and stick feeder supported |

| Vision System | Up-looking camara for component automatic calibration (component size applicable: 22mm×22mm); down-looking camera for PCB calibration via Mark Point and component positioning |

1. Manual machines are the least expensive form of machines, and as such, come with the least amount of features. They are a significant step up from hand-placing, but easily out-performed by most of the other forms of equipment. They are referred to as manual since the user manually moves the nozzle to the desired coordinates before allowing the system to place the component. Manual systems can be a good solution for people who are just starting out or having low volumes of PCBs.

2. A semi-automatic pick & place requires the user to hand-place each component before it's added to the PCB. Instead of placing components via measurements made by the eye, you can use a software that guides them toward the proper placement of each component.

3. An automatic pick and place machine is more typical for those who make large quantities of printed circuit boards that require consistency and reliability between each part made. They come with programmable interfaces that allow the user to program detailed instructions into the system.