CHARMHIGH TECHNOLOGY LIMITED |

|

Verified Suppliers

|

|

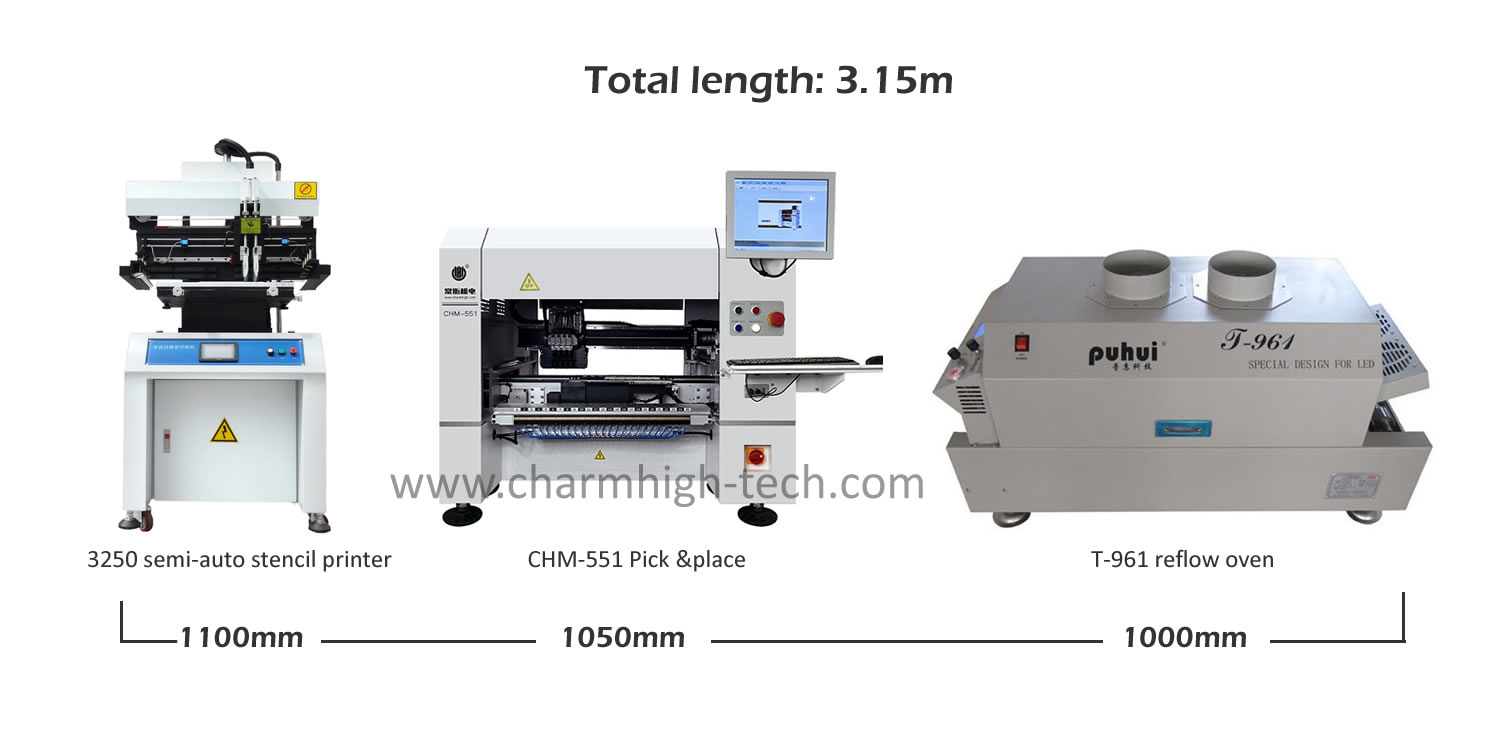

High Precision & Economical SMT Production Line:

3250 semi-auto stencil printer, CHM-551 SMT Chip Mounter, Reflow Oven T961

Small SMT Production Line , high configuration, CPK test passed, min component 0201

1. Stencil Printer 3250 Technical Parameters

| Model | 3250 |

| Dimension | 850x670x1550(mm) |

| Table size | 320x500(mm) |

| PCB size | 250x400(mm) |

| Stencil size | 550x680(mm) |

| Printing speed | 0~8000(mm)/Min |

| PCB thickness | 0~100(mm) |

| PCB slightly adjust range | Front/ Side +10mm |

| Voltage | 1PAC220V 50/60HZ |

| Printing table height | 850±20(mm) |

| Repeat accuracy | ±0.01mm |

| PCB positioning way | Outside/Reference hole |

| Weight | Approx. 250Kg |

2. CHM-551 SMT Pick and place machine

| CHM-551 Specifications | |

| Dimensions | 980mm(L)X 1050mm(W) X 880mm(H) |

| Weight | 190kg |

| Power Supply | AC220V (50Hz,single phase) 1.5kw |

| Air Supply | 0.5MPa ~0.7MPa |

| Vacuum Generation | vacuum pump |

| Mounting Head Quantity | 4 |

| Mounting Speed | 11500CPH (optimal) IPC9850: 8850cph |

| Mounting Accuracy | (XY)±0.06mm; CPK≥1.0 |

| Component Height | 12mm |

| Component Type | 0201/0402/0603~5050/SOT/SOP/QFP/QFN/BGA, etc. (resistor/capacitor/diode/triode/LED/IC, etc.) |

| PCB Thickness | 0.6mm~3.5mm |

| PCB Size | 350mm(L)x270mm(W) (Standard); 600mm(L)x350mm(W) (Optional) |

| Nozzle Change | Automatic nozzle change (13-hole nozzle library) |

| Control System | Built-in industrial computer (Windows 7) equipped with monitor, keyboard, and mouse |

| Drive System | X&Y axis driven by servo motors; adopting flexible S-curve acceleration and deceleration |

| Transmission System | Ball screw + linear guide |

| Feeding System | 50 Yamaha 8mm standard pneumatic/electric feeder stacks (also suitable for IC tray and stick feeder) |

| Vision System | Snapshot camera×4 (component size applicable: 14mm×14mm); IC camera×1 (component size applicable: 25mm×25mm); Mark camera×2 |

3. T961 parameters:

| Model | T-961 |

| The heating zone quantity | upper3/down3 |

| The length of the heating zone | 730mm |

| The heating type | intelligent level sirocco and rapid infrared heating |

| The cooling zone quantity | 1 |

| Maximum width of PCB board | 230mm |

| The operation direction | left→right |

| Delivery options | Net transmission&chain transmission |

| The speed of conveyer belt | 0-290mm/min |

| The power supply | 220V 50/60Hz |

| Peak power | 3.5KW |

| Heating up time | Around 7mins |

| Temperature control range | Room temperature-300 |

| Temperature control mode | PID closed-loop control |

| Temperature control accuracy | ±1 |

| PCB temperature distribution deviation | ±2 |

| Overall dimensions | 1000×466×445mm |

| Machine weight | 70KG |

1. Semi-auto solder paste printer 3250

2. CHM-551 four heads full automatic SMT pick and place machine, highlight:

1. Support CPK test, CPK≥1.0

2. Automatic nozzle change (13 sets nozzle library)

3. Thermal Compensation

4. Automatic PCB conveying

5. Optimal speed:11500CPH, IPC9850:8850CPH

6. Min 0201 supported

7. Ball screw + linear guide

8. Servo motors

Very precice for fine pitch IC:

3. T961 lead-free reflow oven, bigger heating size 730x230mm, for double layer PCB:

Best combination SMT line, we recommend it! Please purcahse with confidence.

Charmhigh factory supply, with quality assurance.

Please send us E-mail or give us a call if you have more questions.

Kindly note:

The CHM-551 smt pick and place machine only need to connect external air source which is prepared by yourself, no need other stuff.

The machine has passed QC passed before ship out.

We provide timely after-sales service, each machine 100% tested well before ship out. Please purchase it with confidence.

Enjoy with your pick and place machine!

Service & Warranty:

The complete machine has a warranty period of 1 year from the time of purchase and lifetime service.

We always provide spare parts of machine, factory reliable direct supply.

We provide online Q/A and troubleshooting support and technical advice service.

Provide one to one after-sale service. Each machine 100% tested well before ship out.

Tech support & Contact:

Kimi Liu

Charmhigh Technology Limited

Mob/ WhatsApp: 0086 135 106 75756

Skype: kimiliu89

E-mail: kimi@charmhigh-tech.com

Welcome to follow us inYouTube: www.youtube.com/c/KimiLiuCharmhigh/videos

If you want to see more information and videos, please contact us by E-mail.

We will response you at the first time.