SHANDONG SMART MACHINERY CO., LTD. |

|

1. Description: This industrial pasta making machine/line/plant/industry pasta making machine/macaroni pasta making machine/pasta production line is produced by single-screw extruder through extruding cooking; the macaroni pasta can be different shapes like shell, spiral, square tube, circle tube, and so on. After drying, the maxaroni pasta needs frying to get expanded.

2. Technical Advantages : Compact structure novel design and stable performance,developed on the base of like produces and requirements in the world market.It realizes high automation,convenient operation,low energy and small floor space,that assures all working procedures from feeding flour to finished once.The investment for this line is only one tenth of that larger size equipment ,especially suitable to small-size or self-owned enterprise.

3. Raw materials: adopts potato starch, corn starch, cassava starch, wheat flour, corn flour etc as raw materials

4. Products: This industrial pasta making machine/line/plant/industry pasta making machine/macaroni pasta making machine/pasta production line can be used to produce Shell, spiral, square tube, circle tube shapes

5. Capacity: 100-120kg/h,280-300kg/h

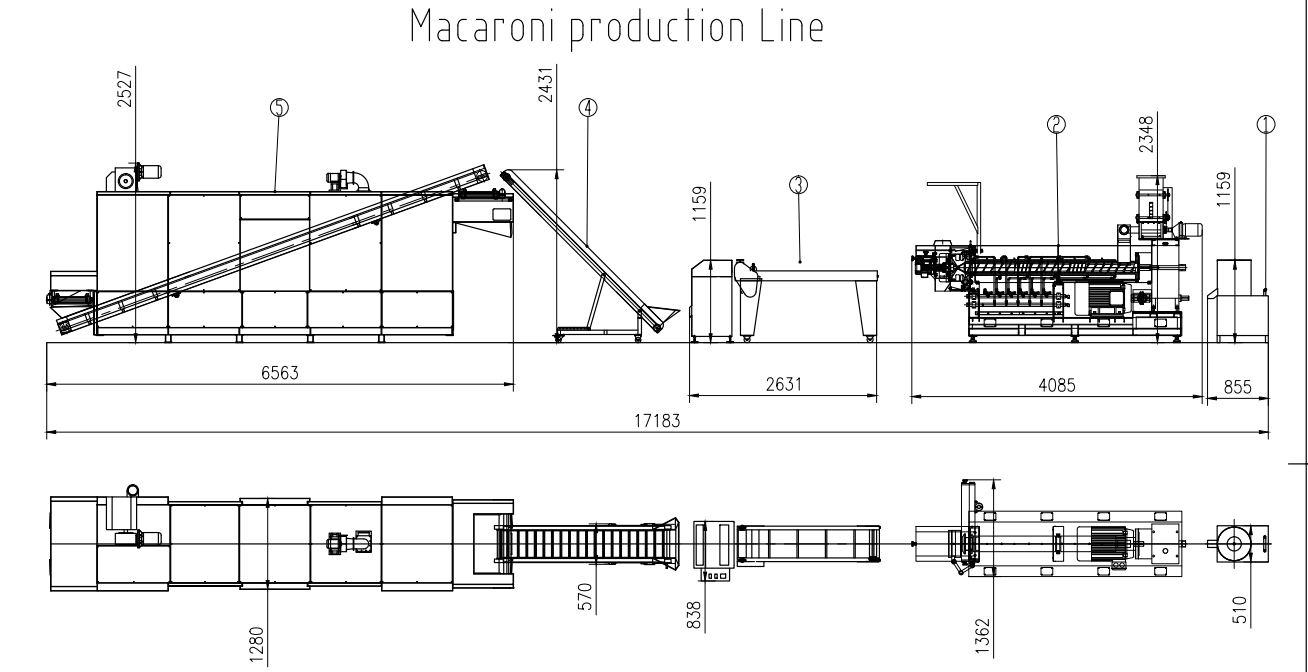

6. Flow chart:Mixing system---Extrusion system----Cutting system---Drying system---Frying system---Flavoring System --Packing system

1. Feeding System

Installed in the main machine, which feeds materials spirally, and the quantity can be adjusted. This system includes engine, screw, blender and machine shelf. The blending wing is used to prevent roller empty although the materials are inside. The speed should be better if the materials are neither accumulated nor stop.

2. Extruding System

Adopts the crafts what can make the materials ripe in the low temperature by blending, cutting and extruding. Temperature control is set strictly on the roller and screw to reach criteria the materials require, thus the stable production can be adjusted according to the food shapes, and enable the materials come out easily and not adhere to the cutter.

3. Cutting System

Includes engine, shelf, cutter and transmitting system. The shelf is fixed on the head of the moulds; and turns and cuts the materials motivated by the belt wheel, the speed of which should be subject to the type of products.

4. Heating System

Divides five areas, and the heating temperature of which can be adjusted separately.

5. Transmitting System

The motive power from the main engine is transmitted to the screw through the triangle belt and decelerator. This system adopts the frequency & speed technology with reliable adjustment.

6. Controlling System

Can control all the components of the main machine centrally. The operation is easy and auto protecting instruments and dashboard.

7.Besides above system,we also have new design with this machine--Vacuum Pump.For the pasta and macaroni,the big problem is with bubbles and air inside.With the vacuum pump,which can extract air from feeding part,so there will be no any air and bubbles inside the pasta and macaroni,and with the vacuum pump,the finished product will not easy broken and taste also very srong and good.