Zhengzhou Zhengtong Abrasive Import&Export Co.,Ltd |

|

Verified Suppliers

|

|

Ceramic blasting media B20 in barrel for Electroplating paint surface pretreatment

DESCRIPTION

The ceramic beads blasting media also called zirconia blasting

sand, zirconia micro blasting beads, is made from zirconium sand,

melting and blending in the high temperature mine heat furnace,

then made to micro beads by special technology. Since its unique

internal crystal phase structure, very fine Zro2 (diameter

generally 1-2um) distributed SiO2 on the substrate, ensuring its

strength and hardness, so that ceramic beads has good wear

resistance and impact resistance performance.

SPECIFICATION

| ZrO2 | SiO2 | Al2O3 | Other |

| 60-66%, | 25-30% max. | 7-13% max. | 5-8% |

| Color | Bulk Density | True Specific Density | Vickers Hardness |

| White | 2.3g/cm3 | 3.85g/cm3 | 700 HV |

Sizes | ||||||

B20: 0.600-0.850mm | B80: 0.125-0.212mm | B170: 0.045-0.090mm | ||||

B30: 0.425-0.600mm | B100: 0.106-0.180mm | B205:0.000-0.063mm | ||||

B40: 0.250-0.425mm | B120: 0.063-0.125mm | B400: 0.030-0.063mm | ||||

B60: 0.125-0.250mm | B150: 0.053-0.106mm | B505: 0.010-0.063mm | ||||

FEATURES

1. Density of ceramic beads is between glass beads and steel shot, the hardness is relatively large, in the range of sand blasting strength, can properly fill the upper and lower limits of the impact strength of glass bead and steel shot.

2. The ceramic bead is light, but the hardness is high, which is very suitable for metal sandblasting strengthening and forming of titanium alloy, aluminum alloy and high temperature alloy.

3. It is more environmentally friendly, has no iron pollution to the processed parts; produces less dust, cleans the working environment, has no hidden dangers to the lungs, and is harmless to the human body.

4. The ceramic bead is not deformed during the recycling process, and the wear is low, which can ensure the consistency of the surface blasting effect in mass production.

5. Ceramic bead has high sphericity, smooth surface and low equipment loss

6. Ceramic bead has a wider range of particle sizes to meet more application needs.

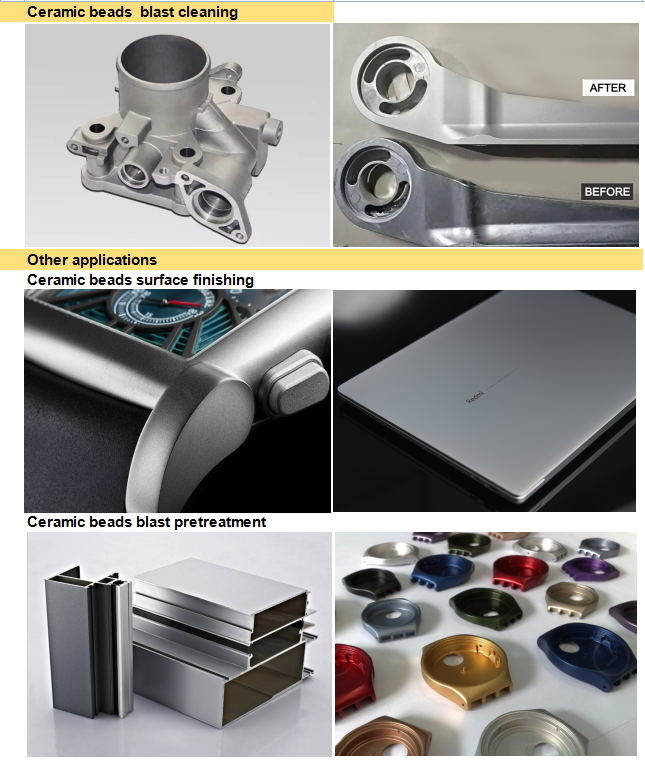

APPLICATIONS

Electroplating, painting, anode-Surface Pretreatment

The ceramic sand blasting process utilizes the impact of high velocity sand flow to clean and roughen the metal surface. The aluminum surface treatment of this method can achieve a certain degree of cleanliness and different roughness of the surface of the workpiece, increase the adhesion between it and the coating, prolong the durability of the coating film, and also facilitate the flow of the coating. Peaceful decoration.

The surface roughness of the part affects the adhesion, appearance, moisture resistance and corrosion resistance of the coating. The pre-treatment work is not done well, and the rust will continue to spread under the coating, causing the coating to fall off. The carefully cleaned surface and the generally cleaned workpieces can have a life difference of 4-5 times. There are many methods for surface cleaning. The more common methods are: solvent cleaning, pickling, and manual tool blasting.

The most practical choice is to choose sandblasting technology, the effect is good, the price is reasonable, and the site is suitable.

With the development of the sandblasting process manufacturing industry, sandblasting can ensure that the basic dimensional accuracy of metal parts does not change; the abrasive does not chemically react with the parts; the surface of the sandblasted parts is not polluted and does not pollute the environment, eliminating the need for Environmental management costs; harmless to the surrounding environment. It can easily handle the difficult parts such as grooves and recesses, and the abrasives of various sizes can be used selectively; the processing cost is greatly reduced, which is mainly reflected in the improvement of work efficiency and can meet various surface finishing requirements. Low cost, energy saving and sandblasting.

Other applications including

3C products ,Aerospace industry, Automotive industry, Kitchen Industry, Machinery, Medical Instrument Sandblast finishing, Casting and forging parts, welded parts, heat-treated parts - Sandblast Cleaning

Pipes, molds - Sandblast cleaning, Electroplating, painting, anode-Surface Pretreatment, Hardware parts - Sandblasting to improve lubrication conditions

APPLICABLE EQUIPMENT

Suitable sand blasting machine:

Manual sand blasting machine, Automatic sand blasting machine,

Open type series of sand blasting machine, and Blasting room series.

CONTACT US

Caroline Cui

Export Director

Zhengzhou Zhengtong Abrasive Imp.&Exp. Co., Ltd

Address: Ximazhuang, Liuzhai Town, Xinmi City, Henan, China

Tel.:+371 86592608

Mob.: +86 15003865330

Email: caroline@zzztabrasive.com