Zhengzhou Zhengtong Abrasive Import&Export Co.,Ltd |

|

Verified Suppliers

|

|

ZrO2 62% Ceramic blasting media B60 Factory supply

DESCRIPTION OF CERAMIC BEADS B60

Ceramic beads blasting media is a spherical micro bead produced by electro-fusion process at a very high temperature. It is extremely tough and fracture resistant, ensuring consistent peening intensities and surface finishes. Also, it is wonderfully useful for cleaning mechanical parts and cost effective because it can be recycled. At the same time, it is one of the most durable media for cleaning thicker items with minimal material removal. This ceramic media for deburring, shot peening is high cost performance abrasive blasting media.

| Product | Process | Specific Density | Bulk Density | Vickers Hardness |

| Ceramic beads | Electro-fusing | 3.85 (g/cm³) | 2.3 (g/cm³) | 700 HV |

| Chemical Components | ZrO2 62-68% | SiO2 25-30% | Al2O3 7-13% | Other 1% Max. |

| Size Available (mm) | Blasting-clean/Surface finish | Shot peening | ||

| B20: 0.600-0.850mm | Z150: 0.150-0.210mm, | |||

| B30: 0.425-0.600mm | Z210: 0.210-0.300mm | |||

| B40: 0.250-0.425mm | Z300: 0.300-0.425mm, | |||

| B60: 0.125-0.250mm | Z425: 0.425-0.600mm, | |||

| B80: 0.180-0.250mm | Z600: 0.600-0.850mm | |||

| B100: 0.128-0.18mm | Z850:0.850-1.180mm | |||

| B120: 0.063-0.125mm | Other sizes can be customized against customers’ requirement. | |||

| B170: 0.045-0.090mm | ||||

| B205 : 0.000-0.063mm | ||||

| B400: 0.000-0.063mm | ||||

FEATURES OF CERAMIC BEADS B60

(1) Surface treatment consistency

Consistency of metallic light, the blasting strength is as good as steel balls processing effect, much higher than

the glass beads strength. And can achieve adequate metal depth.

(2) Environmental Friendly

Low crushing rate, no dust, uniform particle size, high wear resistance, re-elasticity, no hidden danger of silicosis,

it is harmless to the human body.

(3) Low equipment loss

Ceramic sand has smooth surface, high sphericity, good elasticity and low wear, can protect the equipment,

whether it is dry spray or wet spray.

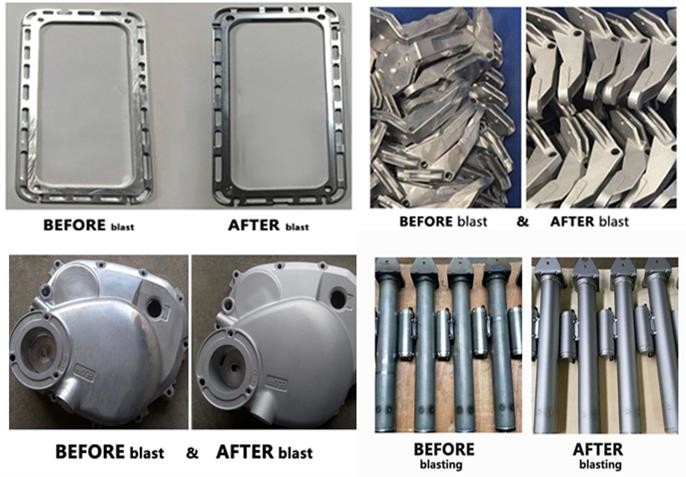

APPLICATION OF CERAMIC BEADS B60

Removal of carbon deposits and other impurities from glass making and ubber tire moulds, without damaging the surface or critical edges.

Deburring

Stainless steel for food and pharmaceutical industries, Medical intrument surface finishing.

Shot peening ferrous and non ferrous items including aircraft engine blades, blisks, turbines etc.

Ceramic beads are easy to handle in all categories of air or wet pressure blasting equipment including pneumatic blasting rooms.

Also well suited for working in most kinds of wheel turbine blasting machines.