Zhengzhou Zhengtong Abrasive Import&Export Co.,Ltd |

|

Verified Suppliers

|

|

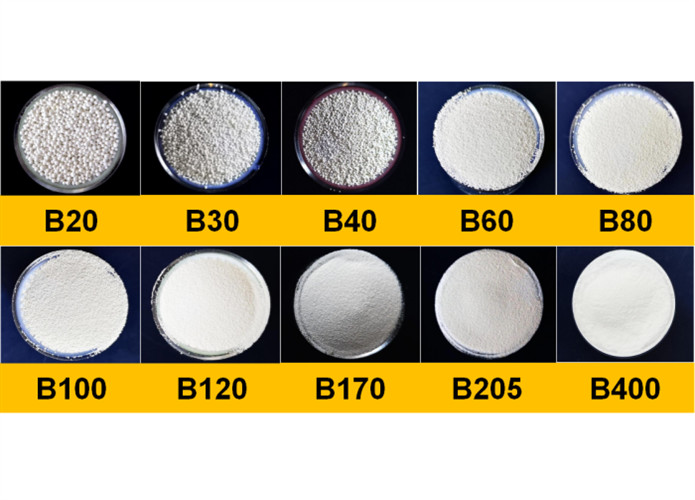

Ceramic Bead Blasting media B205 applicable equipment Automatic sandblasting machine

Ceramic beads is a spherical sandblasting media with smooth surface, good elasticity and concentrated granularity.

It is a sandblasting media used for sandblasting and surface finishing.

The fine grain part B120-B505 is often used for sandblasting finishing of stainless steel, aluminum alloy, titanium alloy, magnesium alloy and other workpiece surfaces, which can produce high-quality finish, eliminate bright light, restore the original color of the metal, and form a unique satin effect.

| ||||||

| Chemical Index | Production Process | True Density | Bulk Density | Hardness | ||

| Vickers | Mohs | Rockwell | ||||

ZrO2 : 60-66% SiO2: 25-30% Al2O3: 7-13% | Smelting | 3.85 | 2.3 | 700HV | 7 | 60HRC |

| ||||||

| B20: 0.600-0.850mm | B80: 0.125-0.212mm | B170: 0.045-0.090mm | ||||

| B30: 0.425-0.600mm | B100: 0.106-0.180mm | B205:0.000-0.063mm | ||||

| B40: 0.250-0.425mm | B120: 0.063-0.125mm | B400: 0.030-0.063mm | ||||

| B60: 0.150-0.300mm | B150: 0.053-0.106mm | B505: 0.010-0.063mm | ||||

| ||||||

| 1. Consistency of spherical shape and sizes provides smooth sating surface finish and consistent results from the first part to the last. | ||||||

| 2.Outstanding elasticity provides a high impact force. | ||||||

| 3. High wear resistance, high impact resistance, and low dust. | ||||||

4. Cost-effective compared to glass beads, media consumption reduced up to 90% Vs glass Beads. | ||||||

| ||||||

| 3C electronic products: Computers, mobile phones, cameras, tablets and other metal, plastic appearance and built-in parts, surface finishing treatment. | ||||||

| Mechanical: overall sandblasting and finishing of mechanical appearance, restore the original color of metal, improve visual effect and texture, such as medical equipment. | ||||||

| Hardware: Polishing of metal parts, deburring, descaling, derusting, degreasing, pre-painting. | ||||||

| Pipes: Copper pipes, steel pipes, and other metal pipes. The inner and outer walls are cleaned and polished. | ||||||

| Molds: glass bottles, tires and other molds to clean up and remove rust, dirt and impurities. | ||||||

| ||||||

| ||||||

| ||||||

25kgs /Barrel+Pallet or 12.5kgs/Barrel, 2 barrels / Paper carton+Pallet

| ||||||