Shijiazhuang Minerals Equipment Co. Ltd |

|

Verified Suppliers

|

|

10 Inch Mining Slurry Pump Horizontal 560kW With High Chrome Impeller

The 10 Inch Slurry Pumps are widely used to transport corrosive/ abrasive and high concentration slurry in many industries. such as Gold, Silver, Iron ore, Tin, Steel, Coal, Titanium, Copper, Mineral sands, Lead and Zinc. Various other industries include Molybdenum, Electric Utilities, Oil Shale, Water & Sewage Utilities, Building areas, Sand & Gravel, Tobacco and Agriculture (hog, poultry, dairy manure), Mining & Minerals, Grinding and screening, Hydrocyclone separation, Magnetic separation, Flotation, Thickening, Filtration, Leaching, solvent extraction and electrowinning, Pelletizing, Tailings, Metallurgy, Roasting, Annealing and pickling, Coke quenching, Hot strip milling, Neutralisation, Mud handling and waste treatment.

Seal Method:

Packing Seal

As one of the most commonly used seals for rotating shafts, the packing seal can come with low-flush or full flush arrangement which uses flushing water to prevent media from escaping the pump housing. This kind

of seal is suitable for use under all pumping conditions. In situations where corrosive solids or high temperature might be encountered, Teflon or aramid fiber is used as the packing material for the gland. For

high abrasion conditions, a ceramic shaft sleeve is available.

Centrifugal Seal - Expeller

The combination of impeller and expeller creates the pressure needed to seal against leakage. Together with the gland seal or lip seal which is used as the shut-down seal, this type of seal can handle sealing requirements for applications where full-flush gland seal is impractical due to lack of water on the site, or sealing water is allowed to enter inside the pumping chamber to dilute the slurry.

Mechanical Seal

R rubber lined heavy duty slurry pump utilizes a leak-proof mechanical seal design which allows easy installation and replacement. Other types of mechanical seal are among options to suit the slurry pump for

various pumping applications.

We also utilize special ceramic and alloys of high strength and hardness on parts that are subjected to friction. Unique design of and seamless fit between the mechanical seal and seal chamber provides excellent resistance to abrasion and shock that ensures its effectiveness under the toughest conditions.

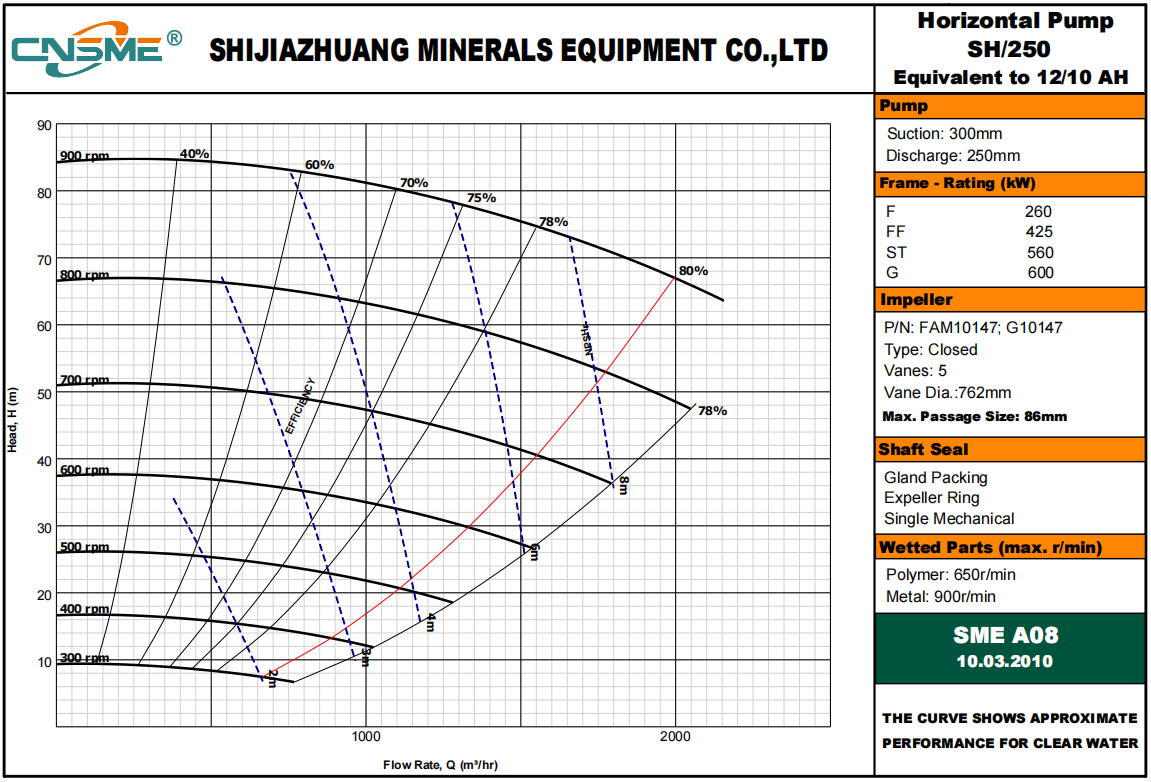

Performance Curve: