Active Member

|

[China]

Address: No.508 Jinshan Road, Jinshan Industrial Park, Hetang District,Zhuzhou City, China

Contact name:Bonnie

ZHUZHOU JINTAI CEMENTED CARBIDE CO., LTD. |

|

Yg6x Tungsten Carbide Rod Composite Rod Welding Rods Raw Material K10 Tungsten Carbide Rod

We Guarantee:

1. produced with advanced equipments and process.

2. high quality durable tungsten carbide rod blanks/cemented rods

for milling for router bits made from 100% virgin raw material.

3. all products go through in-process and final inspection.

4. Quality Control System and strict inspection.

5. stable and continuous production ability.

6. free online technical service available.

7. OEM and ODM are accepted as well.

8. Our solid carbide rods are known for constantly providing

maximum quality. You can rely on our products as a basis for

consistent performance capacity of your tools.

9. Undertake orders of non-standard sizes at customer's requests.

Material composition:

1.Physical Properties:

A) Hardness greater than or equal to 92.8 HRA;

B) Density greater than or equal to 14.2 g/cm³;

C) TRS greater than or equal to 4200 N/mm²;

D) Free of ETA phase condition;

E) No contamination by other materials;

F) Porosity = A00 / B00 / C00 ;

G) Uniform and consistent grain size. No grain size can be larger

than specified.

H) Chromium carbide grain growth inhibitor only.

2.All the production, coatings are used in Germany, Switzerland,

processing equipment;

3.It's proposed cutting less than 60HRC;

Properties of cemented carbide grades recommended rods | |||||||

Grade | Chemical composition | Physical data | Grain size of WC(um) | ||||

| WC | Co | Others | Density(g/cm³) | Hardness(HV3) | TRS(MPa) |

|

YL10.1 | 93.5% | 6.0% | 0.5% | 14.88-15.04 | 1580±50 | 2500 | 1.2-1.7 |

YL10.2 | 89.5% | 10.0% | 0.5% | 14.4-14.55 | 1600±50 | 4000 | 0.8 |

YL10.5 | 89.7% | 9.5% | 0.8% | 14.4-14.55 | 1550±50 | 3800 | 0.7-0.9 |

YL50 | 85.0% | 15.0% |

| 13.86-14.10 | 1095 | 2060 | 0.4-0.6 |

YU06 | 93.0% | 6.0% | 1.0% | 14.7-14.8 | 2050 | 3000 | 0.2-0.4 |

YU08 | 91.0% | 8.0% | 1.0% | 14.56-14.65 | 1900 | 4000 | 0.2-0.4 |

YU09 | 89.8% | 9.0% | 1.2% | 14.36-14.50 | 1950 | 3900 | 0.2-0.4 |

YU12 | 87.0% | 12.0% | 1.0% | 14.05-14.15 | 1750 | 4000 | 0.2-0.4 |

YF06 | 93.5% | 6.0% | 0.5% | 14.86-14.96 | 1800 | 3800 | 0.4-0.6 |

YF08 | 91.4% | 8.0% | 0.6% | 14.55-14.65 | 1800 | 3900 | 0.4-0.6 |

YG6X | 93.5% | 6.0% | 0.5% | 14.8-15.10 | 91 | 1560 | 1.0 |

YG8 | 92.0% | 8.0% |

| 14.6-14.9 | 89.5 | 1840 | 1.2-1.6 |

~ Customized Tungsten carbide products are available!

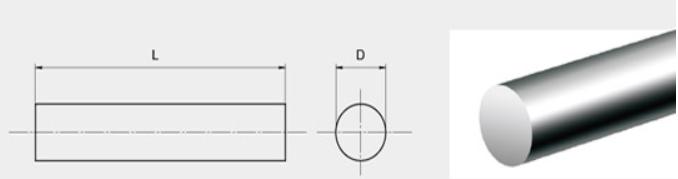

| Type | D(mm) | Tol. Of diameter(mm) | L(mm) | Tol. Of diameter(mm) |

| ¢1.0*330 | 1.0 | +0.2~+0.45 | 330 | 0~+5.0 |

| ¢2.0*330 | 2.0 | +0.2~+0.45 | 330 | 0~+5.0 |

| ¢3.0*330 | 3.0 | +0.2~+0.45 | 330 | 0~+5.0 |

| ¢4.0*330 | 4.0 | +0.2~+0.45 | 330 | 0~+5.0 |

| ¢5.0*330 | 5.0 | +0.2~+0.45 | 330 | 0~+5.0 |

| ¢6.0*330 | 6.0 | +0.2~+0.45 | 330 | 0~+5.0 |

| ¢7.0*330 | 7.0 | +0.2~+0.45 | 330 | 0~+5.0 |

| ¢8.0*330 | 8.0 | +0.2~+0.45 | 330 | 0~+5.0 |

| ¢9.0*330 | 9.0 | +0.2~+0.45 | 330 | 0~+5.0 |

| ¢10.0*330 | 10.0 | +0.2~+0.5 | 330 | 0~+5.0 |

| ¢11.0*330 | 11.0 | +0.2~+0.5 | 330 | 0~+5.0 |

| ¢12.0*330 | 12.0 | +0.2~+0.5 | 330 | 0~+5.0 |

| ¢13.0*330 | 13.0 | +0.2~+0.5 | 330 | 0~+5.0 |

| ¢14.0*330 | 14.0 | +0.2~+0.5 | 330 | 0~+5.0 |

| ¢15.0*330 | 15.0 | +0.2~+0.6 | 330 | 0~+5.0 |

| ¢16.0*330 | 16.0 | +0.2~+0.6 | 330 | 0~+5.0 |

| ¢17.0*330 | 17.0 | +0.2~+0.6 | 330 | 0~+5.0 |

| ¢18.0*330 | 18.0 | +0.2~+0.6 | 330 | 0~+5.0 |

| ¢19.0*330 | 19.0 | +0.2~+0.6 | 330 | 0~+5.0 |

| ¢20.0*330 | 20.0 | +0.2~+0.7 | 330 | 0~+5.0 |

| ¢21.0*330 | 21.0 | +0.2~+0.7 | 330 | 0~+5.0 |

| ¢22.0*330 | 22.0 | +0.2~+0.7 | 330 | 0~+5.0 |

| ¢23.0*330 | 23.0 | +0.2~+0.7 | 330 | 0~+5.0 |

| ¢24.0*330 | 24.0 | +0.2~+0.7 | 330 | 0~+5.0 |

| ¢25.0*330 | 25.0 | +0.2~+0.7 | 330 | 0~+5.0 |

| ¢26.0*330 | 26.0 | +0.2~+0.8 | 330 | 0~+5.0 |

| ¢27.0*330 | 27.0 | +0.2~+0.8 | 330 | 0~+5.0 |

| ¢28.0*330 | 28.0 | +0.2~+0.8 | 330 | 0~+5.0 |

| ¢29.0*330 | 29.0 | +0.2~+0.8 | 330 | 0~+5.0 |

| ¢30.0*330 | 30.0 | +0.2~+0.8 | 330 | 0~+5.0 |