Anping Jiongcan Hardware Mesh Products Co., Ltd |

|

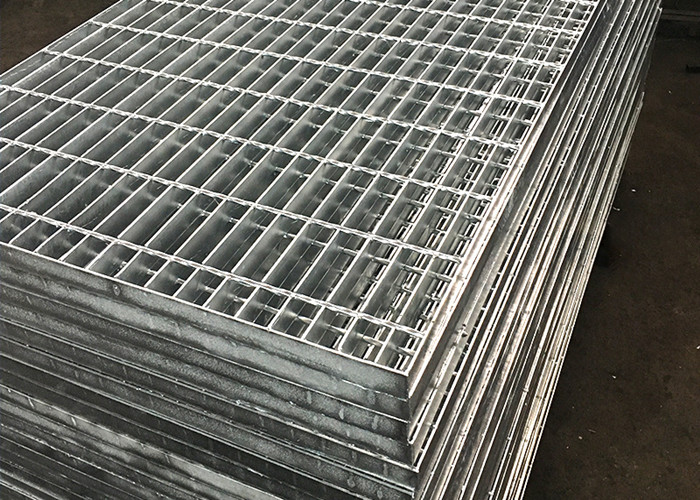

Steel grid plate is also called steel grid plate, grid plate is

made of flat steel in accordance with a certain distance and cross

bar arrangement, and welded into a kind of steel products with

square grid in the middle, mainly used to do ditch cover plate,

steel structure platform plate, steel ladder step plate, etc.

The bar is generally made of twisted square steel.

Steel grid plate is generally made of carbon steel, hot dip

galvanized surface, can play a role in preventing oxidation.

It can also be made of stainless steel.

Steel grille plate has ventilation, lighting, heat dissipation,

anti-skid, explosion-proof and other properties.

| Product name | Steel Grating |

| Finish | Hot galvanized ,Paint,Untreatment (black/slef color) |

| Weld way | Automatic pressure resistance welding |

| Usage | Industrial platform, Corridor laying, Ditch cover plate, Fence, etc |

| Thickness | 3-10mm |

| Bearing bar pitch | 20mm 30mm 40mm |

| Cross bar pitch | 50mm 100mm |

| Style | Plain sheet,Serrated sheet,I type sheet |

1. Generally used specifications are: 30/30, 30/50, 30/100, 40/100, etc.

2, steel grid size: 1000mm*1000mm, 1000mm*1200mm, 1200mm*1500mm, 1500mm*2000mm.

3. The steel grid plate is an open steel member which is composed of the bearing flat steel and the horizontal bar in accordance with a certain distance and is fixed by welding or pressing lock;The bar is generally made of twisted square steel, circular steel or flat steel. The material is divided into carbon steel and stainless steel.The steel grid plate is mainly used to make steel structure platform plate, ditch cover plate, steel ladder step plate, building ceiling and so on.

4, steel grid plate is made of load flat steel and bar according to a certain distance of latitude and longitude arrangement, using 200 tons of hydraulic resistance welding automation equipment welding into the original plate, after cutting, opening, packaging and other processes and products required by customers.

5, the loading flat steel spacing: two adjacent loading flat steel center distance, commonly used 30mm, 40mm two kinds.

The use of the stepping board is very wide, in the power plant,

water plant and other factories, and municipal engineering,

sanitation engineering and other fields of platform, walkway,

theater, visit platform, parking lot and other large places on the

ground platform, have a wide range of applications.

Material saving: the most material saving method under the same

load conditions, and accordingly, can reduce the material

supporting the structure.

Reduce investment: save material, save labor, save time limit, free

cleaning and maintenance.

Construction is simple: in the pre - installed support with bolt

clip fixed or welding fixed, one can be completed.

Time saving: no on-site reprocessing, quick installation.

Durable: hot dip zinc anticorrosive treatment before delivery,

strong impact resistance and heavy pressure ability.

Modern style: beautiful appearance, standard design, ventilation

and light, give people with the overall smooth modern feeling.

Light structure: less material, light structure, and easy to lift.

Anti-sedimentation: no rain, snow, ice and dust.

Reduce wind resistance: due to good ventilation, wind resistance is

small in case of strong wind, reduce wind damage.

Simple design: no need for small beams, simple structure, simple

design;

No need to design detailed steel grid plate, only indicate the

model, the factory can be on behalf of customers to design the

layout map.

Ventilation, lighting, heat dissipation, explosion-proof, anti-skid

performance is good: acid and alkali corrosion ability: within the

range of pH 6 to pH 12.5, the surface of zinc layer forms a stable

protective film, good corrosion resistance.

Can choose welding and installation clamping two ways.

The advantage of welding is that it is permanently fixed and will

not be loosened. The specific position is on the first flat steel

at each corner of the steel grid plate. The weld length is not less

than 20mm and the height is not less than 3mm.

The advantages of the mounting clip are the destruction of hot dip

zinc layer and easy disassembly. Each plate needs at least 4 sets

of mounting clips. The number of mounting clips increases with the

increase of the length of the plate.

The safest method is not to clamp the screw head directly welded to

the beam, to ensure that the steel grid plate will not slip from

the beam due to the loosening of the mounting clip.

Delivery when will we have a professional inspectors to check the

quality of the product is unqualified, such as qualified will paste

the qualified product certificate, and then fixed by shipping

packaging, packaging with the steel plate on the metal tray, and

then fixed with metal packing tape, finally wrapped by plastic film

packaging, general each pallet packing 1-2 tons of cargo, in order

to convenient for unloading and storage after the arrival of the

goods. The unqualified products will be recalled by our quality

inspector.

After the customer orders, we will have professional technical

personnel to contact with the customer, in order to meet the

customer's technical inquiry and production schedule.

After the goods are shipped, we will have professional technical

personnel to docking with customers, so that when the goods arrive,

there will be unloading problems, storage and installation

problems. Our technical personnel will reply online within 24

hours. If there is a problem, we will docking within 2 hours and

help customers solve the problem within 5 hours.