Shaanxi Dewin Technology Co., Ltd. |

Product Specification

Product name | Aluminum Alloy Die Casting Parts for Motor Bracket |

Material | A360,ADC12,A380,ZL101,102,114,etc |

Surface Treatment | plating chrome or nickel, sandblasting,shotblasting,powder coating,painting etc |

Material Density | 2.73g/cm3-2.9g/cm3 |

Quality Assurance | ISO9001:2008 Certified/SGS/ROHS |

Casting Max Size | Aluminium die casting parts: Up to 80''*80''*50'' |

Finishing | Milling;Drilling |

File Formats | Solid Works, STP, IGS,DWG,SLD,PDF,TIF etc. |

Aluminum die casting Product Advantages

1. High load capacity and accuracy

2. High density and hardness

3. Wear and corrosion resistance

4. Precision reference point correction

5. It saves metal materials and labor costs

6. High thermal conductivity

7. Has good fluidity and plasticity

Aluminum die casting product feature:

1.Aluminum die casting has good fluidity and is suitable for the production of thin-walled parts. For example, Led lamp radiator shell, led street lamp shell, etc. Because the secondary processing of the die casting is less, the production efficiency is also faster.

2. It can produce metal parts with complex shapes, clear outlines and thin walls and deep cavities. Since the molten metal maintains high fluidity at high pressure and high speed, it is possible to obtain metal parts that are difficult to process by other processes.

Aluminum die casting Quality Control

Each product are carefully inspection from the blank to the finished.Customer satisfaction is our eternal pursuit.

1.Regularly scheduled dimensional production checks using the latest in applicable measuring technology

2.Complete customer-owned tooling maintenance program.

3.In-house Continual Improvement Team, which uses customer and company feedback to constantly increase our effectiveness in meeting or exceeding our customers' demands.

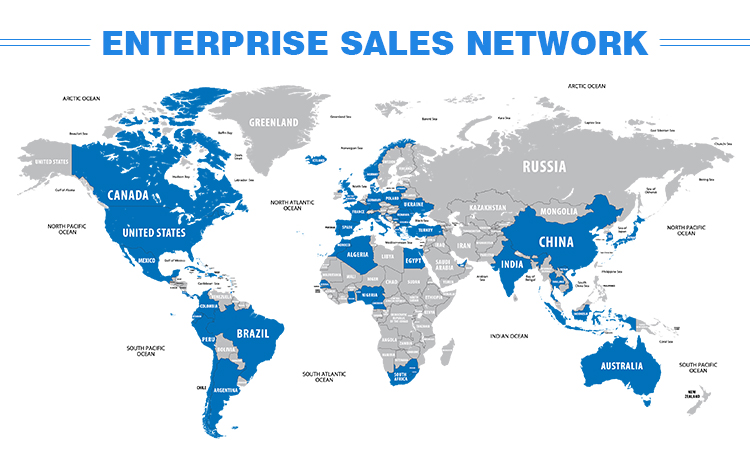

Our Clients

We are able to provide customers with a wide range of quality products that can be customized. Good reputation, reasonable price and perfect after-sales service are what we always insist on.

Our clients distribute widely, but most of them come from Europe and America, Such as, lGermany, Norway, Poland, Finland, Spain, UK, France, Russia,USA, Canada, Brazil, Mexico, and other continental many countries.

FAQ

Q: Are you trading company or manufacturer?

A: We are a factory main produce aluminum die casting, zinc die casting, cnc parts and tooling molds.

Q: How long is your delivery time?

A: Mold lead time: Within 30 days upon we receive the 50% of mold charges.

Batch production lead time: With 15 days upon we receive the 30% deposit.

Q: Can you make the parts based on the samples?

A: Yes, we could make measurement based on your samples and make the tooling die.

Q: What is your terms of payment?

A: Mold: 50% deposit + 50% after the samples is approved.