Dongguan Drow Precision Alloy Co., Ltd. |

|

Verified Suppliers

|

|

Application Field:

Tungsten solid carbide saw blades with its high hardness widely use in cutting, grooving and milling, involving in parts manufacturing, mold industry, 3C communication, automotive industry, aerospace, medical machinery etc.

For safety and reliability, solid carbide circular saw blades should only be used on stable and low-vibration machines (preferably milling machines). For steel machining, a particularly greasy cooling is recommended. In the case of machining of non-ferrous metals, spray lubrication can also be used. Gray cast iron and plastics can be machined dry.

How to Choose Teeth Number?

By processed materials.If working on steel part, try to use item with more teeth number, which lead to higher wear-resistance.

But if working on aluminum or copper parts, try to use item with less teeth. It will benefit to remove the chips and not let them affect saw blade's working.

How to Apply Saw Blade by Materials?

| Milled Materials | Ordinary Steel | Titanium Alloy | Brass | Stainless Steel |

| Vc(m/min) | 70 - 160 | 20 - 60 | 200 - 350 | 80 - 150 |

| Milled Materials | Chilled Steel | Aluminium Alloy | Cast Iron | |

| Vc(m/min) | 50 - 80 | 200 - 400 | 110 - 130 |

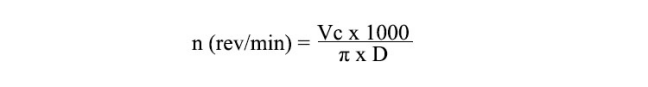

Above are tooth milling line speed (Vc, m/min) of solid carbide slitting saw according to sever different milled materials. Once the Vc of diameter of saw blade (D, mm) was confirmed. The rotate speed (n, rev/min) of milling cutter arbor can be calculated

And if cutter speed (St, mm/T) was required, with tooth number of cutter (T). The cutting feed speed (Vf) can be calculated:

Product Details---High Hardness Saw Blades

1.Material: Tungsten Carbide, 100% New Material with high wear resistance and hardness.

2.Usage:Suitable for metal cutting, such as aluminum, aluminium alloy, copper metal, stainless steel, Easy Car Iron, PVC, etc.

3.Specification:D10~180mm,Thickness0.2~6.0mm,6~280T.

4.Customization: It's available to specialize your order according to your drawings. Kindly provide us

some necessary parameter include Outer diameter, thickness, inner

hole diameter, number of teeth, as well as the material you require

to process.

Product Features:

1. High-precision mirror treatment for every saw blade

2. High-precision air-avoidance grinding, make cutting fast and smooth, the incision surface is smooth and burr-free

3. Imported machine tool precision grinding

4. Due to the latest tool technology and the highest quality standards, Drow solid carbide circular saw blades achieve greatest cutting speeds.

Product Specification:

Specification example as below shows, other specifications can be supported if you need to customize.

Outside Diameter mm | Thickness mm | Inner Diameter mm | Teeth Number |

| 10 | 0.2~4 | 4/5 | 6~24 |

| 12 | 0.2~4 | 4/5/6 | 6~30 |

| 16 | 0.2~4 | 5/6/8 | 6~40 |

| 20 | 0.2~4 | 5/6/8 | 6~45 |

| 22 | 0.2~5 | 5/6/8 | 8~50 |

| 25 | 0.2~5 | 6/8/10 | 10~56 |

| 30 | 0.2~5 | 6/8/10 | 10~60 |

| 32 | 0.2~6 | 6/8/10/12.7 | 10~60 |

| 35 | 0.2~6 | 8/10/12.7 | 10~60 |

| 40 | 0.2~6 | 8/10/12.7 | 10~80 |

| 45 | 0.2~8 | 10/12.7/16 | 10~80 |

| 50 | 0.2~8 | 10/12.7/16 | 10~100 |

| 55 | 0.2~8 | 12.7/16 | 24~120 |

| 60 | 0.2~8 | 12.7/13/16 | 24~120 |

| 70 | 0.3~8 | 16/22/25.4 | 28~120 |

| 75 | 0.5~8 | 16/22/25.4 | 30~120 |

| 80 | 0.5~8 | 22/25.4 | 30~128 |

| 85 | 0.5~8 | 22/25.4 | 30~128 |

| 90 | 0.5~8 | 22/25.4 | 30~160 |

| 95 | 0.5~8 | 22/25.4 | 30~160 |

| 100 | 0.5~8 | 22/25.4/27 | 30~160 |

| 105 | 0.8~8 | 22/25.4/27 | 30~160 |

| 110 | 0.8~8 | 22/25.4/27/32 | 30~180 |

| 115 | 0.8~8 | 22/25.4/27/32 | 30~180 |

| 120 | 1~10 | 22/25.4/27/32 | 30~240 |

| 125 | 1~10 | 22/25.4/27 | 30~240 |

| 130 | 1~10 | 22/25.4/27/32 | 30~240 |

| 150 | 1~10 | 22/25.4/27/32 | 40~240 |

| 160 | 1~10 | 22/25.4/27/32 | 40~240 |

| 180 | 1.5~12 | 25.4/27/32/40 | 60~280 |

Why Choose Us

1.Consistent Quality: Continuous production of carbide slitting saw

blade over 10 years.Total production quantity of carbide slitting

saw blade up to hundreds of tons.We’ve received many good feedback

or reviews from lots of customers.

2. On-time Delivery: Our products widely exported to

UK,USA,Australia,Russia, Southeast Asia etc. Punctual delivery is

one of our competitive advantages in current fierce global market.

3. Comprehensive Service: We,Drow Carbide Tools,is capable of

quotation your order with 24 hours and help you select adaptive

products per your application requirements.

4. Attractive Price and Long Tool Life

If you have any questions about metal saw blades, welcome to inquiry! Or if you have interest to join us , welcome to be our agents.

Production Machinery:

| Machine Name | Brand & Model No. | Condition |

| Surface Grinding Machine | Confidential | Available |

| Grinding Wheel Dressing Machine | Confidential | Available |

| Grinding Wheel Pre Setter | Confidential | Available |

| Cylindrical Grinding Machine Internal | Confidential | Available |

| Centerless Grinding Machine | Confidential | Available |

| 5-Axis CNC Grinding Machine | Confidential | Available |

| Edge Preparing Machine | Confidential | Available |

| Cylindrical Grinding Machine | Confidential | Available |

| Laser Marking Machine | Confidential | Available |

| Sand Blasting Machine | Confidential | Available |

| Cutting Off Machine | Confidential | Available |

Quality Control Machine:

| Machine Name | Brand & Model No. | Condition |

| Runout Tester | Confidential | Available |

| Balance Tester | Confidential | Available |

| Projector | Confidential | Available |

| Image Measuring Machine | Confidential | Available |

| Height Hauge | Confidential | Available |

| Tooling Inspection and Inspection Machine | Confidential | Available |

| Micrometer | Confidential | Available |

| Electronic Microscope | Confidential | Available |

FAQ

Q1: How can we trust your product quality?

A: 100% products quality inspection for first batch, and casual

inspection for the coming batch.Raw material will be tested before

bulk production and we will check the physical properties, shape

and tolerance for ensuring qualified products before shipping

Q2: What else can you buy from us?

A: Carbide insert,carbide end mill,carbide drill,carbide

boring,cutting tools&customized carbide precision molds.

Q3: Can we get a discount if our ordered quantity is big enough ?

A: Yes. If your ordered quantity is big enough , we can offer you our best price and will give you a discount.

Q4. Could you offer OEM and ODM service?

A:It’s okay , we have more than 10 years experience in OEM

service.Our professional R&D team is dedicated to design

products to fit various demands of customers. They can always offer

the professional advice and solutions for you!

Q5:Do you accept low volume for sample order? And what’s your MOQ for

special tools?

A: Yes, we do. For sample order, MOQ one piece is accepted, and the

sample lead time is 2-3 days. It can be negotiated for special

requirement.