Zhuzhou Gold Sword Cemented Carbide Co., Ltd. |

|

Verified Suppliers

|

|

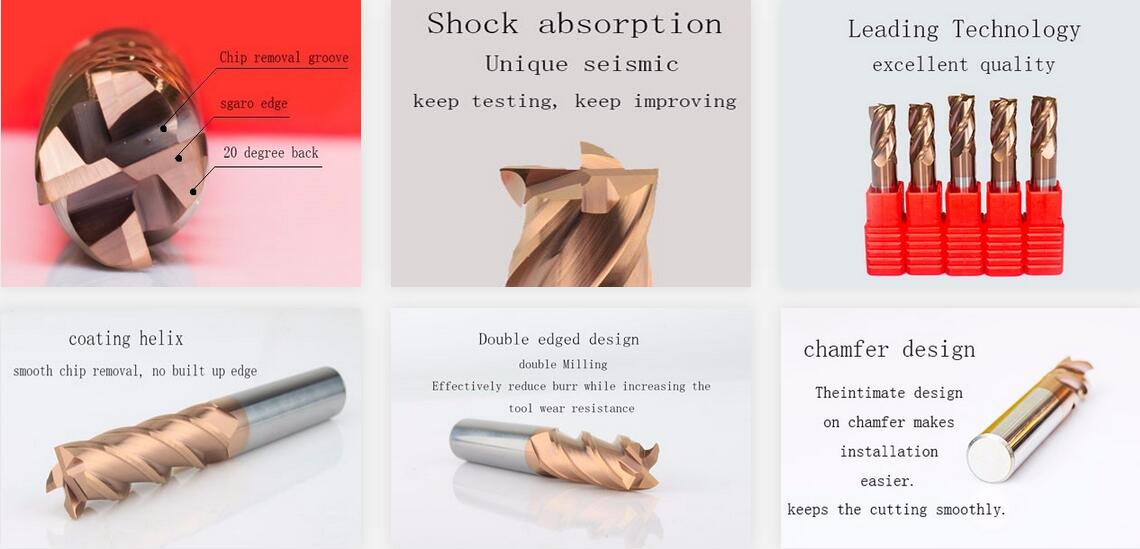

Carbide End Mills for metal cutting,solid round tools

Description of Carbide End Mills

| Item | Carbide End Mill | Brand | GW | Materials | tungsten carbide |

| Flutes | 2/3/4/6 flutes | HRC | 45/50/55/65 | Coating | AlTiN /TiAIN/TiSiN/Nano |

| Choice | square, ball nose, aluminum, corner radius, roughing, micro and long neck from 1T to 6T | ||||

| Helix Angle | 35/45 | Suitable materials | 45 steel, cast iron, tool steel | ||

| Suitable Machne | CNC center, Engraving machine, High speed machine, Grinding machine | ||||

| Unique sharp edge with 20 degrees back angle, to achieve the effect

of shock absorption, cutting process stability. cutting process stability. The deep chip removal groove and the big spiral angle ensure the smooth chip removal. Using the new ultra-fine particle tungsten carbide rod with high hardness and strength which make the end mills in perfect performance. | |||||

Coating Sheet

| AlTiN | TiAIN | TiSiN | Nano | |

| Hardness(HV) | 3200 | 2800 | 3600 | 42(GPA) |

| Thickness(UM) | 2.5-3 | 2.5-3 | 3 | 3 |

| Oxidation Temp(°) | 900 | 800 | 1000 | 1200 |

| Friction Coeffient | 0.3 | 0.3 | 0.45 | 0.4 |

| Color | Black | Violet | Copper | Blue |

Applicable

Applicable materials: steel, stainless steel, alloy steel, quenched

and tempered steel, carbon steel, cast iron, heat-treated quenched

steel.

The new ultra-fine tungsten steel substrate has high wear

resistance and strength. As a versatile milling cutter, it is

specially designed for high hardness and high speed cutting

applications. The blade is covered with TiIN coating, which can

directly perform high-speed rough machining on heat-treated

materials below 45°. When performing fine machining, the number of

tool changes is reduced and the machine is moved ahead of time,

thereby saving manufacturing time and focusing on surface/side

milling for fine cutting.

Detall Information