Zhuzhou Aohua Tools Co.,Ltd. |

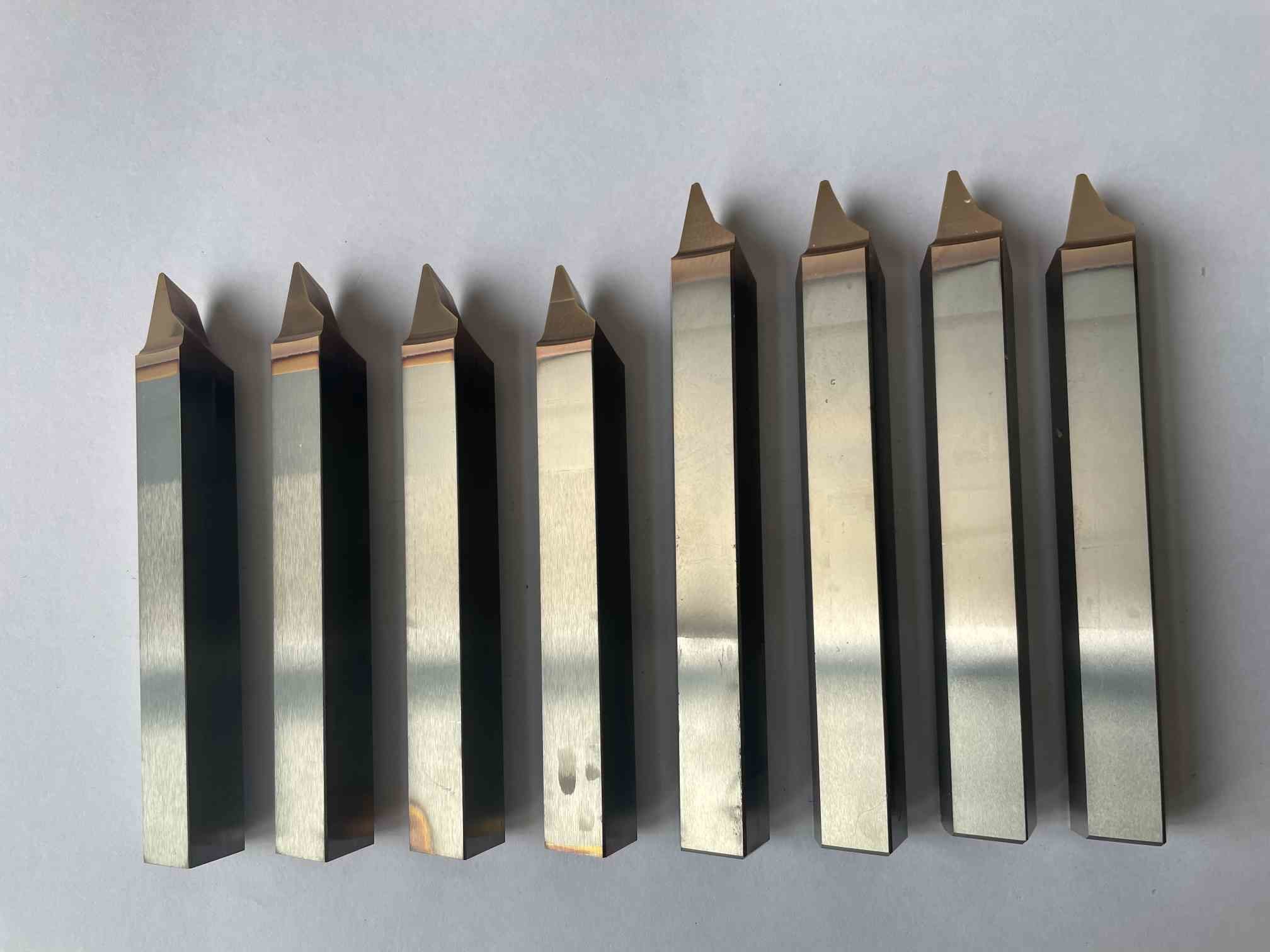

Chinese name: Coated tool

Foreign name: Coated tool

Category: Blades

Features: Coated

use: processing

There are two coating methods commonly used in production: physical vapor deposition (PVD) and chemical vapor deposition (CVD). The deposition temperature of the former is 500°C, and the coating thickness is 2~5μm; the deposition temperature of the latter is 900°C~1100°C, the coating thickness can reach 5~10μm, and the equipment is simple and the coating is uniform. Because the PVD method does not exceed the tempering temperature of the high-speed steel itself, the PVD method is generally used for high-speed steel tools, and the CVD method is mostly used for cemented carbide. When cemented carbide is coated by CVD method, due to its high deposition temperature, a brittle decarburized layer (η phase) is easily formed between the coating and the substrate, resulting in brittle fracture of the insert. In the past ten years, with the advancement of coating technology, cemented carbide can also use the PVD method. In foreign countries, a combination of PVD/CVD technology has also been used to develop a composite coating process, which is called PACVD (plasma chemical vapor deposition). That is to say, the use of plasma to promote the chemical reaction can reduce the coating temperature to below 400 °C (the coating temperature can be reduced to 180 °C ~ 200 °C), so that there will be no diffusion between the cemented carbide substrate and the coating material. The phase transition or exchange reaction can maintain the original toughness of the blade. This method was reported to be particularly effective for applying diamond and cubic boron nitride (CBN) superhard coatings.