Factop Pharmacy Machinery Company |

|

Verified Suppliers

|

|

NJP-7800C capsule filling machine 000 medicine powder capsule maker machine Features:

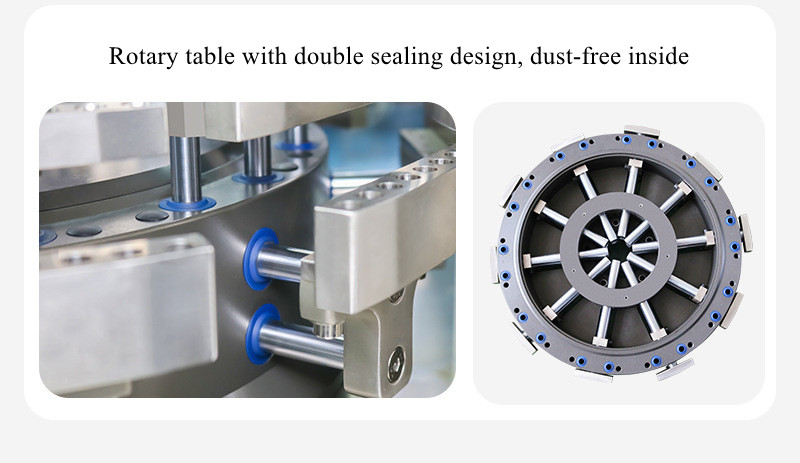

The capsule maker machine adopts a fully enclosed twelve station

turntable, and the upper and lower modules are designed with four

rows of 55 holes arranged in a row

1. The turntable uses airtight technology to fill the inside of the

turntable with gas, creating a pressure difference between the

inside and outside of the turntable, preventing the powder from

entering the inside of the turntable.

2. Lowering the center of gravity of the transmission mechanism

significantly reduces the vibration during equipment operation,

greatly improving the stability and service life of the machine.

3. The transmission camshafts are replaced by slot camshafts, which

increase the transmission force and reduce mechanical failures

caused by vibration and spring fatigue.

4. Automatic lubrication system, timed automatic lubrication of

various transmission components to reduce pollution caused by

manual operation.

5. Standard clamps are used for all interfaces of the feeding

section, making loading, unloading, and cleaning more convenient.

6. The cleaning and capsule extraction stations are equipped with

visual glass for easy observation of the machine's operating

status.

7. The intelligent remote control of the host allows for easy

operation and personnel safety by holding a remote control to

control the jog and trial operation after mold cleaning or

equipment maintenance.

Technical Parameter NJP-7800C capsule filling machine 000 medicine powder capsule maker machine

| Model | NJP-7800C |

| Production capacity | 468000pcs/hour |

| Machine weight | 3500kg |

| Dimension | 1880*1390*2400mm |

| Voltage | 220/380V 50HZ |

| Motor | 13kw |

| Holes number | 55 holes |

| Vacuum | -0.04 to -0.08MPa |

| Dust | 24.5Kpa, 210m3/h |

| Air compressure | 12m3/h, 0.3-0.4MPa |

| Noisy | 78dBA |

| Accuracy | Empty 99.99%, Full 99.98% |

| Suitable | 000#-5# |

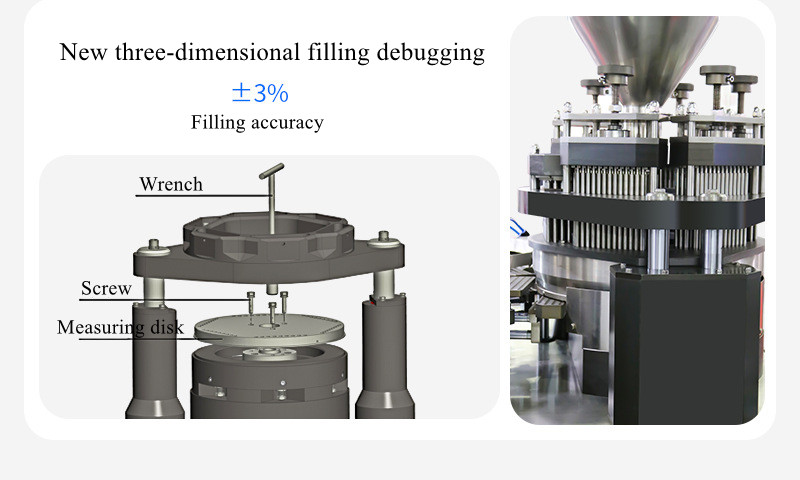

| Filling accuracy | West-medicine 3%, Chines-medicine 4% |

| Filling type | Powder, granule, pellets, tablets |

NJP-7800C capsule filling machine 000 medicine powder capsule maker

machine advantages:

1. Sowing bladder: Three groups of bladders, with the body bladder

at the lower end and the cap bladder at the upper end. With

pneumatic negative pressure, the upper and lower bladders are

successfully separated

2. Split the capsule: make the body capsule and cap capsule

misaligned;

3. Filling: The body capsule automatically enters the powder

filling mechanism and is filled with powder or pellets;

4. Reject: The problem capsules that have not been separated by 1

will be automatically rejected at the station;

5. Reserved space for microcapsules: when half is powder and half

is pellets, a pellet filling device needs to be added;

6. Capsule: cap and body sac merge;

7. Capsule release: Capsules leave the mold and are automatically

discharged;

8. Cleaning: Automatically clean the upper and lower molds so that

there is no dust in the mold holes and improve the effect of

sowing.

NJP-7800C capsule filling machine 000 medicine powder capsule maker machine wearhouse show:

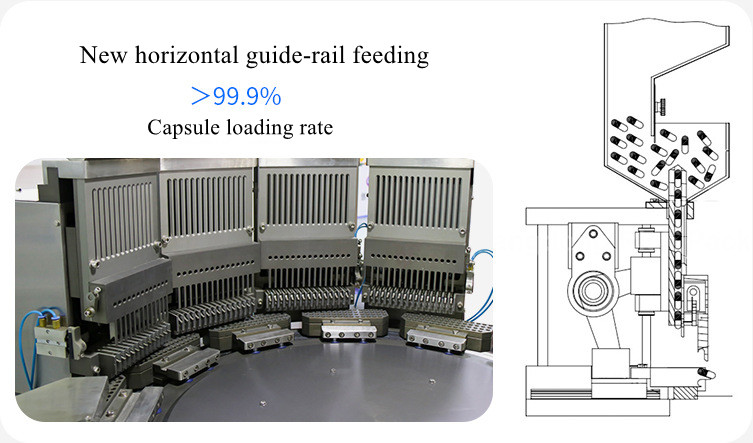

NJP-7800C capsule filling machine 000 medicine powder capsule maker machine detail show:

Detail photos show:

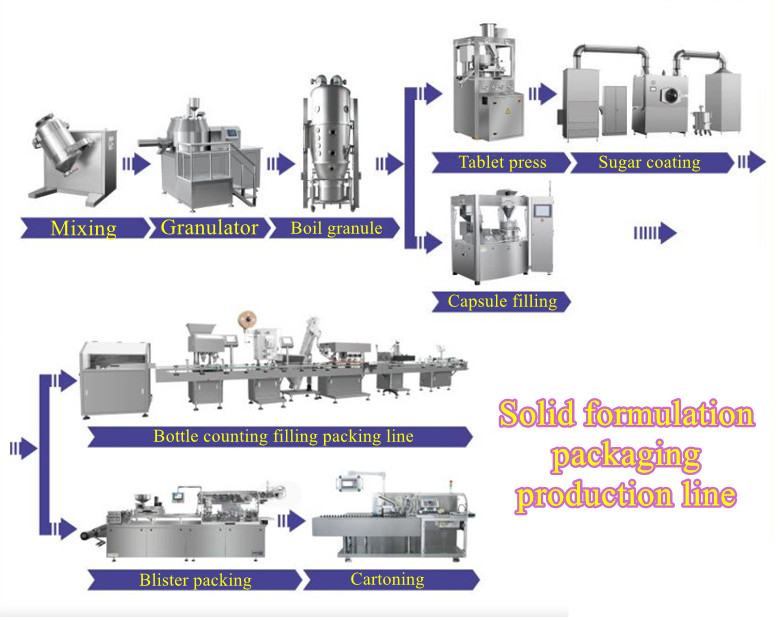

NJP-7800C capsule filling machine 000 medicine powder capsule maker machine Application:

Tags: capsule filling machine, automatic capsule filling machine, capsule filling machine pharmaceutical