SHANGHAI LWT INTELLIAENT TECHNOLOGY CO.,LTD |

|

Verified Suppliers

|

|

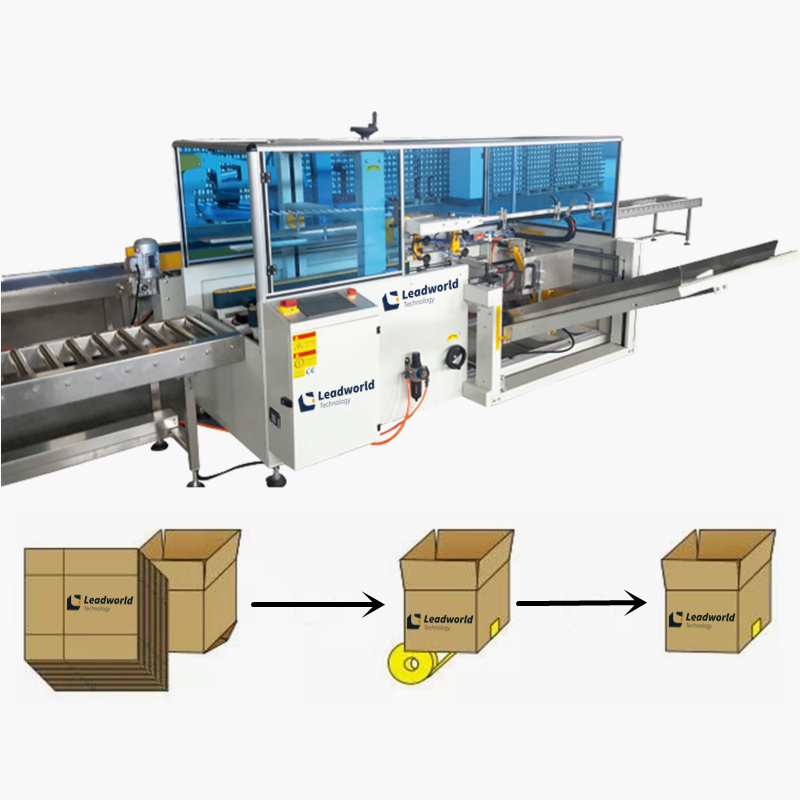

1.Vertical storage,cartons can be added at any time without stopping the machine.

Model | LW-EV18 | LW-EH30 | LW-EH50 |

Capacity | 18pcs/min | 30pcs/min | 50pcs/min |

Carton collecting | 100pcs(1000mm) | 80pcs(800mm) | 80pcs(1000mm) |

Carton size | L:250-400mm W:150-350mm H:100-350mm | L:240-510mm W:190-400mm H:120-400mm | L:250-450mm W:150-400mm H:100-300mm |

Power | 220V 1Φ 200W | 380V 3Φ 746W | 380V 3Φ 746W |

Air Consumption | 0.6Mpa 450NL/min | 0.5Mpa 300NL/min | 0.5Mpa 300NL/min |

Machine Size | L2400*W1200*H1450mm | L2372*W1210*H1820mm | L3120*W1250*H1740mm |

Belt Size | 48,60,75mm | 2'',2.5'' | 2'',2.5'' |

Our Service

Pre-sales: According to client-specific machinery or automatic product line requirement, supply reasonable machine sketch map, quotation, and similar video for client ref first.

During Sales:

1) Depends on the client's need to custom base on the standard machine.

2) Repeat 20 ongoing hours testing equipment operation stability.

3) Execute GMP certification for the equipment and materials used in the production process requirement and specification strictly.

After-Sale:

1. we will assign professional engineers to customer companies for installation or maintenance services according to customer needs;

2. Supply systematic operation training for client workers.

3. After client use the machine for several years, we can provide a detailed refurbishment program, the original equipment and replacement of hardware and software upgrades, extend machine service life for more than 3-4 years.

4. If quality problems arise, the supplier provide technical support and timely supply wearing parts.