SHANGHAI LWT INTELLIAENT TECHNOLOGY CO.,LTD |

|

Verified Suppliers

|

|

Shampoo filling production line is suitable for filling various bottles of shampoo, shampoo, shower gel, conditioner, facial cream, etc. Niwei provides you with a fully automatic shampoo filling production line to help you arrange your production layout more reasonably and make your shampoo production line management more convenient. It is an ideal choice for shampoo companies.

Automatic Filling Production Line

1. Qty of filling head: 2~12 heads (depending on the design).

2. Filling capacity: 50ML-5000ML (Compatible filling capacity tolerance for a single machine is one time. To be determined by customer requirements).

3. Filling method: Equal-liquid level self-flowing type.

4. Filling speed: 6~8 times/min. Custom Filling head

5. Filling accuracy: ±1%.

6. Program control: PLC + touch screen.

7. Main materials: #304 stainless steel, PVC used in food industry.

8. Air pressure: 0.6-0.8Mpa.

9. Conveyer belt: Stainless steel chain belt of 82mm in width. Speed: 0-15m/min. Distance away from the ground: 750mm±25mm.

10. Conveyor motor: 370W frequency conversion speed regulation motor.

11.Power: 1KW/220V single phase.

12. Capacity of material tank: 200L (with liquid level switch).

13. Protective device: Outage alarm on shortage of liquid in the reservoir tank.

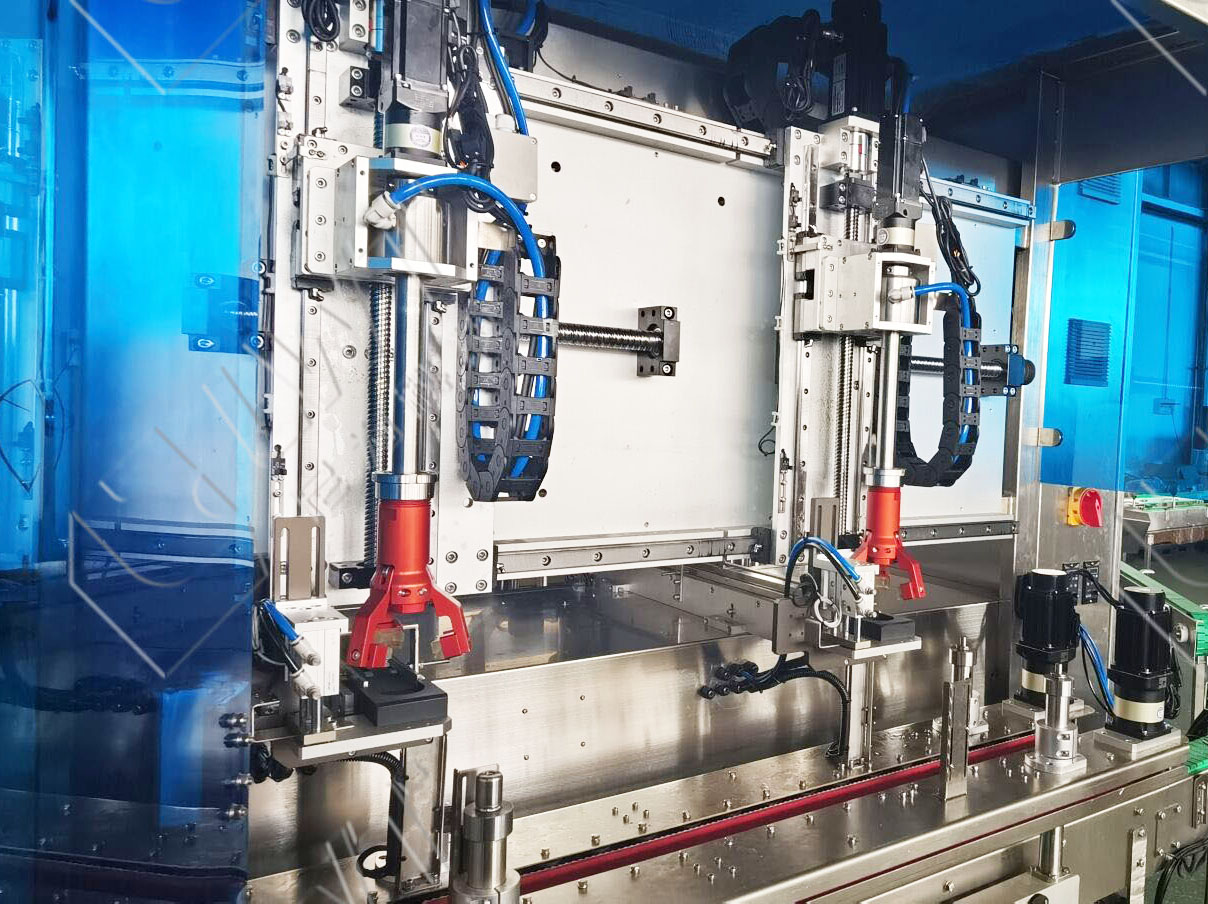

Capping Machine

Automatic capping machines, specifically servo capping machines, utilize a servo system to automatically track the position of the bottle and cap the cap. This servo system ensures accurate and precise capping, improving efficiency and reducing errors in the capping process.

Case Packer

The fully automatic case packer is widely used in industries such as food, daily chemicals, and chemicals. It is mainly used for packaging bucket-packed jams, concentrates, beverages, and various canned products.

The fully automatic case packer is composed of a frame, bottle feeding conveyor, box feeding conveyor, bottle suction unit, box opening mechanism, and electrical cabinet.

Palletizing Machine

| Model | Filler volume | Air consumption | Filling accuracy | Total power | Machine size(mm) |

| LW-FPP-4A | 10-60g | 120L/Min | liqud≤±0.5%Paste≤±1% | 3P 380V,50/60Hz 1.369KW | L2200*W1020*H2250 |

| LW-FPP-6A | 30-100g50-250g | 140L/Min | liqud≤±0.5%Paste≤±1% | 3P 380V,50/60Hz1.69KW | L2500×W1020×H2250 |

| LW-FPP-8A | 100-500g | 160L/Min | liquid≤±0.5%Paste≤±1% | 3P 380V,50/60Hz 2.07KW | L2500×W1020× H2250 |

| LW-FPP-10A | 200-1000g500-2500ml | 180L/Min | liquid≤±0.5%Paste≤±1% | 3P 380V,50/60Hz 2.82kw | L3000×W1020×H2250 |

| LW-FPP-12A | 1000-5000ml | 300L/Min | liquid≤±0.5%Paste≤±1% | 3 P 380V,50/60Hz 2.82kw | L3000×W1020×H2250 |