electrical controlling system. The working way adopts magnetic suction and moving type. It can match with magnetic lifting conveying system, can transport product in the air and can transport product among different height of floor.

SHANGHAI LWT INTELLIAENT TECHNOLOGY CO.,LTD |

|

Verified Suppliers

|

|

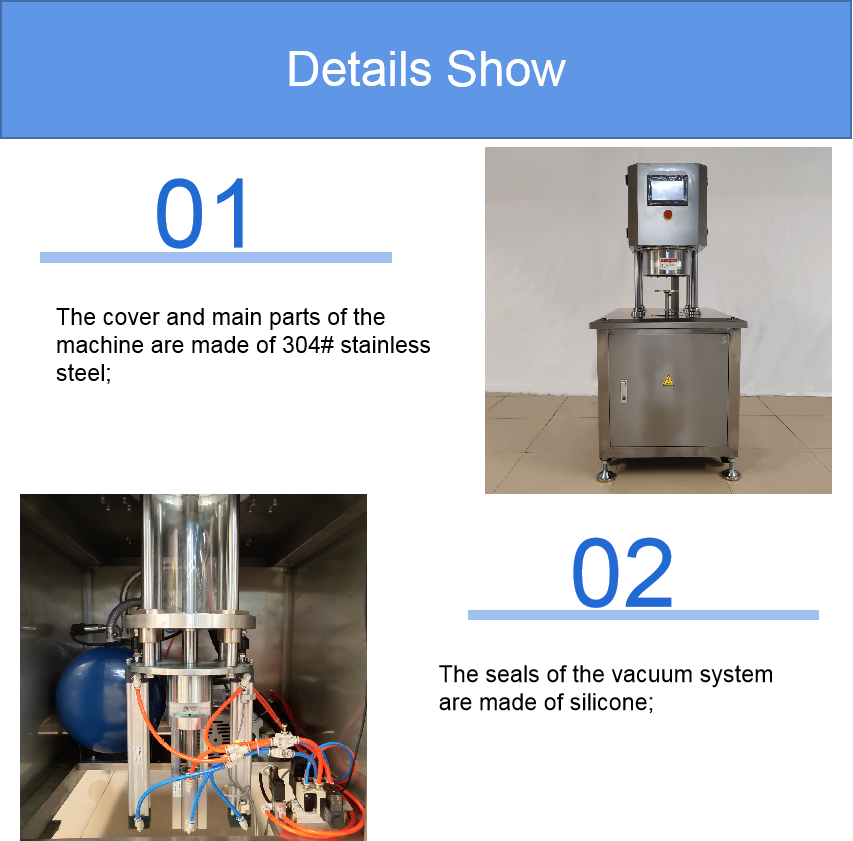

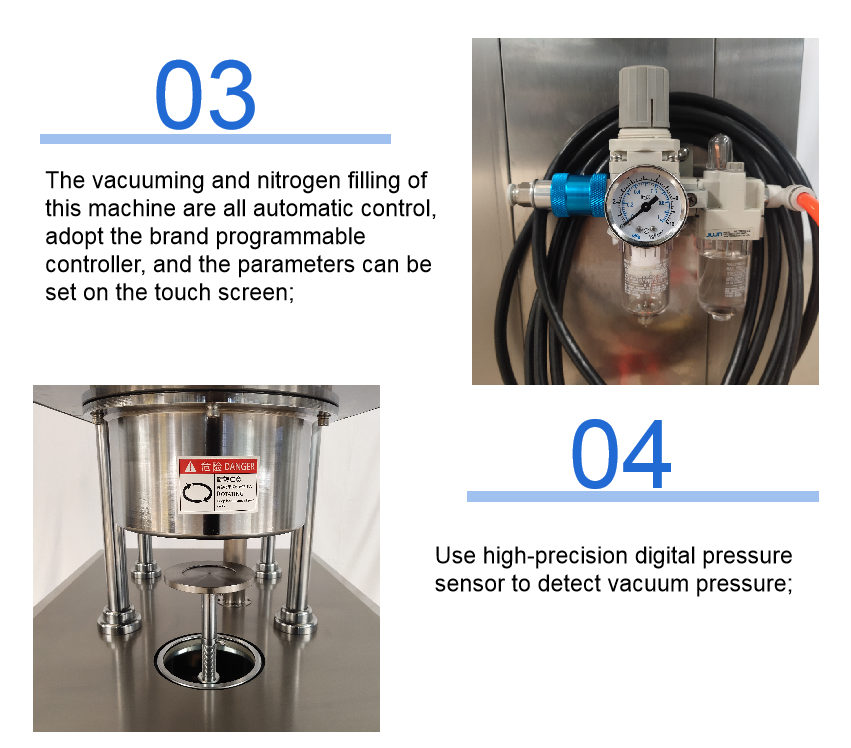

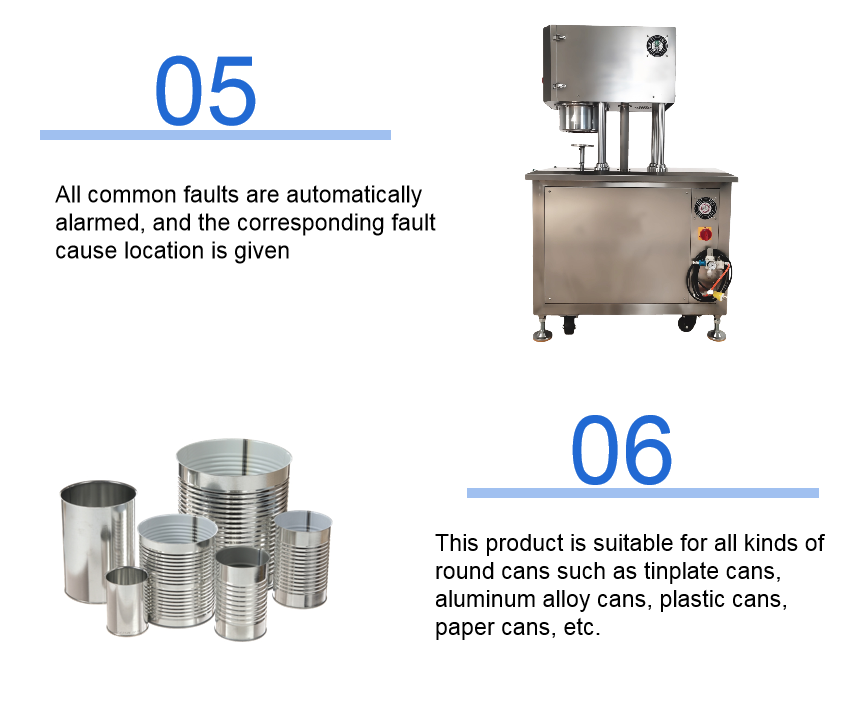

Product Name | LW-8000A Semi-automatic Vacuum Nitrogen Can Sealing Machine |

Material | 304# Stainless Steel |

Cans diameter | 50-140mm |

Cans height | 50-200mm |

Capacity | 4-8pcs/min(or OEM) |

Power | 1.5KW/50Hz/220V |

Machine size | L1050*W800*H1650 mm |

Weight | 300kg |

Support bottle type | Tinplate cans, aluminum alloy cans, plastic cans, paper cans |

Name | Empty Bottle Washing Machine | LW-WM100 | |

Capacity | 50-300 bottle/min | 50-100 cans/min | |

Washing Section | 1-2 Section washing | 1 Section washing | |

can diameter | 40-150mm | 40-150mm | |

Power | 1.5KW | 1.1KW | |

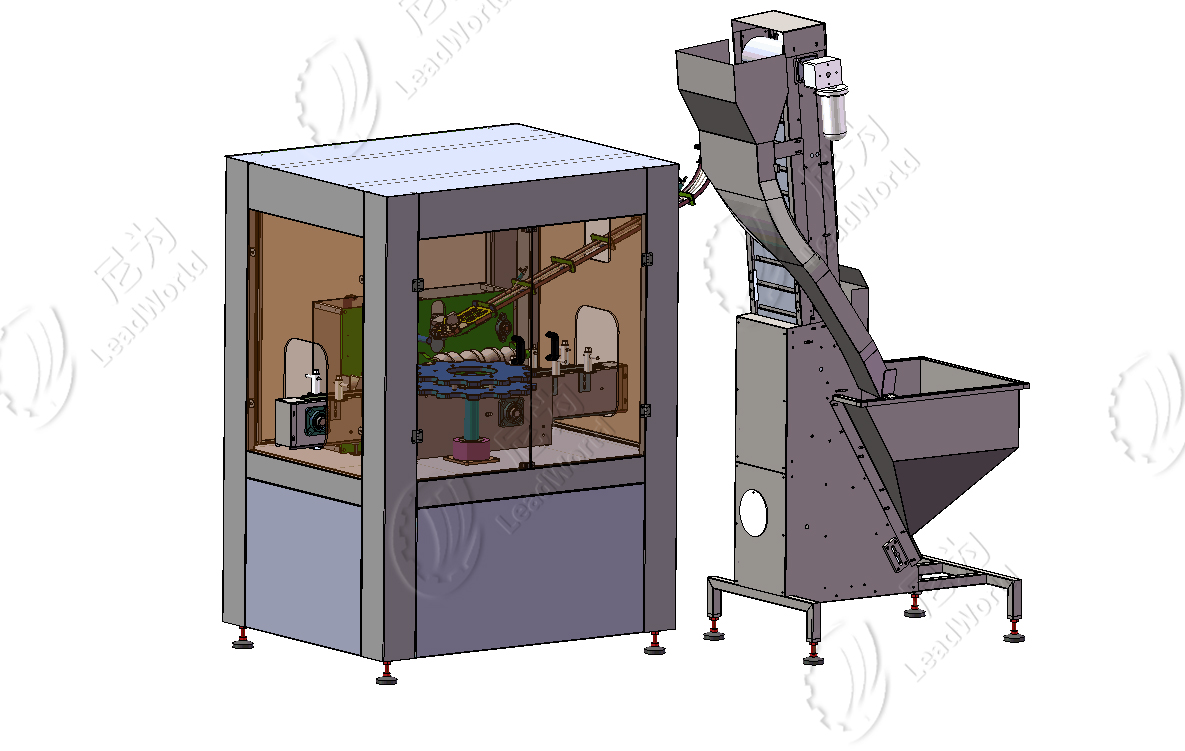

Moldel | Capacity | Filling volume |

LW-FPP-4A | 480bph-720bph | 10-60g 30-100g 50-250g 100-500g 200-1000g 500-2500g 1000-5000g |

LW-FPP-6A | 960bph-1920bph | |

LW-FPP-8A | 1440bph-2880bph | |

LW-FPP-10A | 1920bph-3840bph | |

LW-FPP-12A | 2400bph-4800bph |