Shenzhen Bwin Precision Tools Co., Ltd. |

|

Quick Detail:

Exquisite workmanship

Stable performance

Durable

Strong universality

High cost performance

Description:

JOMW/JDMW milling carbide insert belongs to rough milling blade, which is most suitable for large feed cutting and rough machining. The products are made of cemented carbide powder, which is pressed and sintered at high temperature. The CNC peripheral grinder is used for fine grinding. Later, the heat resistance, oxidation resistance and wear resistance of the products are consolidated by coating, which can effectively enhance the basic wear resistance of cemented carbide and achieve stable processing under different working conditions.

Specifications:

Brand | BWIN |

Model | JOMW06T215 JOMW080320 JDMW09T320 JDMW120420 |

Color | Fuchsia |

Workpiece | Steel/Stainless steel |

Type | CNC Grooving Cutting Tool |

Material | Tungsten Carbide Grooving Insert |

Processing Type | Medium Cutting |

Feature | Exquisite workmanship |

Stable performance | |

Durable | |

Strong universality | |

High cost performance | |

Standard | ISO |

Quantity | 10pcs/box |

Weight | 0.015kg |

Package | Plastic Box |

Customized Support | OEM, ODM |

Notice:

1.The milling carbide insert shall not be collided or dropped on the ground and must be handled with care.

2.Before installing the milling carbide insert, the performance and purpose of the saw table must be confirmed to ensure that the cutting direction indicated by the blade arrow is consistent with the rotation direction of the saw table. It is strictly prohibited to install in the opposite direction. Wrong installation direction may cause the blade sawtooth to fall off, so as to prevent accidents.

3.After installation, it is necessary to confirm whether the central hole of the milling carbide insert is firmly fixed on the flange plate of the saw table. If there is a gasket, the gasket must be sleeved; Then, gently push with your hand to confirm whether the blade rotates eccentrically.

4.When using, do not exceed the specified high speed

5.When the milling carbide insert is not used, hang the blade vertically on the dry shelf.

Applications:

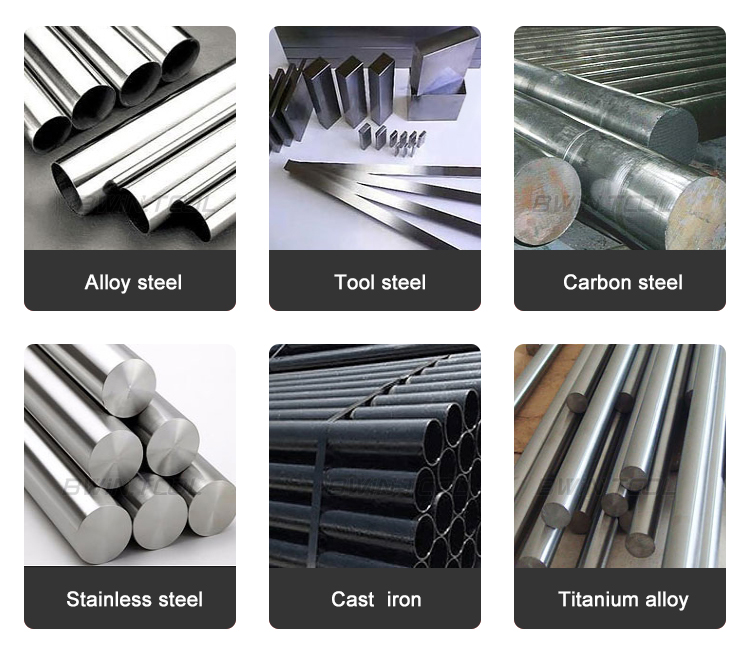

Our milling carbide insert could to be processed Alloy steel, Tool steel, carbon steel, stainless steel, Cast iron and Titanium alloy. Working material as following:

1. Flank Wear? Higher cutting resistance,Notch wear on flank,Poor roughness of surface, or deterioration of accuracy.