Shenzhen Bwin Precision Tools Co., Ltd. |

|

Quick Detail

Description:

Specifications:

| Brand | BWIN |

| Model | SEKT1204ATFN-XM |

| Color | Black |

Workpiece | Cast iron |

Type | Milling |

| Material | Carbide Milling Blade |

| Processing Type | Medium Cutting |

| Feature | Special process manufacturing |

| Stable performance | |

| Good toughness | |

| Strong impact resistance | |

Longer life | |

| Standard | ISO |

| Quantity | 10pcs/box |

| Weight | 0.015kg |

| Package | Plastic Box |

| Customized Support | OEM, ODM |

Lead Time:

| antity(pieces) | 1 - 3000 | >3000 |

| Lead time (days) | 7 | To be negotiated |

Notice:

Applications:

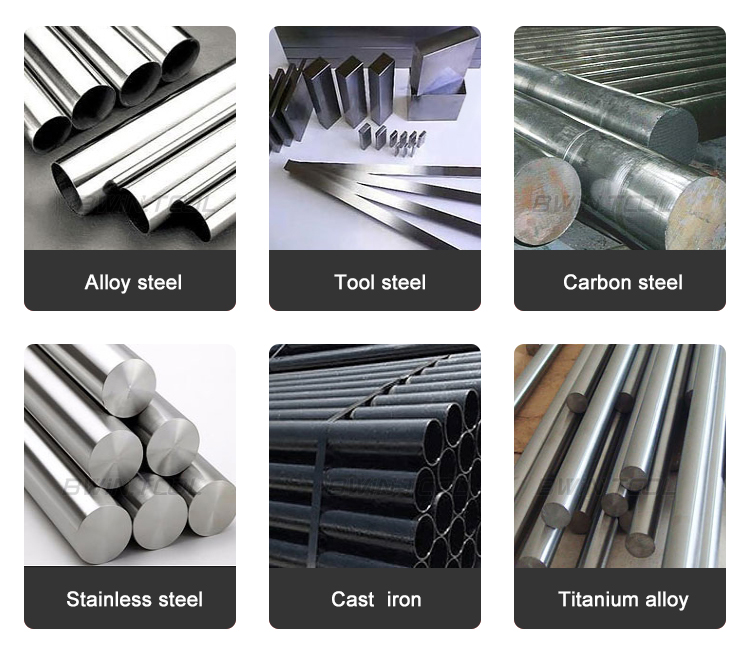

Our milling carbide insert could to be processed Alloy steel, Tool steel, carbon steel, stainless steel, Cast iron and Titanium alloy. Working material as following:

Advantage

1. Honest merchants, reasonable price and quality assurance

2. Large inventory, sufficient supply and high cost performance

3. Customer service responds in time and delivers goods quickly

4. Provide after-sale guarantee to make your after-sale service free