Shenzhen Bwin Precision Tools Co., Ltd. |

Custom Cnc Lathe Carbide Turning Insert Dnmg 150608 Dnmg150404 Metal Machine Tool

Quick Detail:

Description:

Specifications:

| Brand | BWIN |

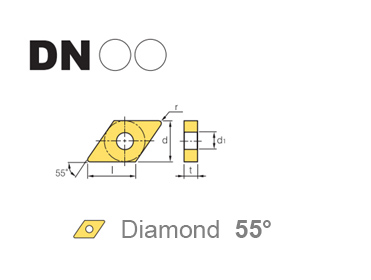

| Model | DNMG150404 DNMG150408 DNMG150412 |

| Color | Yellow/Brown/Fuchsia/Black/cermet/Uncoated |

| Workpiece | Cast iron/Steel/Stainless steel/Aluminium |

| Type | CNC Carbide lathe Insert |

| Material | Tungsten Carbide lathe Insert |

| Processing Type | Medium Cutting |

| Feature | Rhombic slotting |

| Sharp edge | |

| Wear resistant and durable | |

| Good heat resistance | |

Smooth cutting | |

| Standard | ISO |

| Quantity | 10pcs/box |

| Weight | 0.016kg |

| Package | Plastic Box |

| Customized Support | OEM, ODM |

Lead Time:

| antity(pieces) | 1 - 3000 | >3000 |

| Lead time (days) | 7 | To be negotiated |

I(mm) | d(mm) | t(mm) | d1(mm) |

11 | 9.525 | 3.18~4.76 | 3.81 |

15 | 12.7 | 4.76~6.35 | 5.16 |

Notice:

Applications:

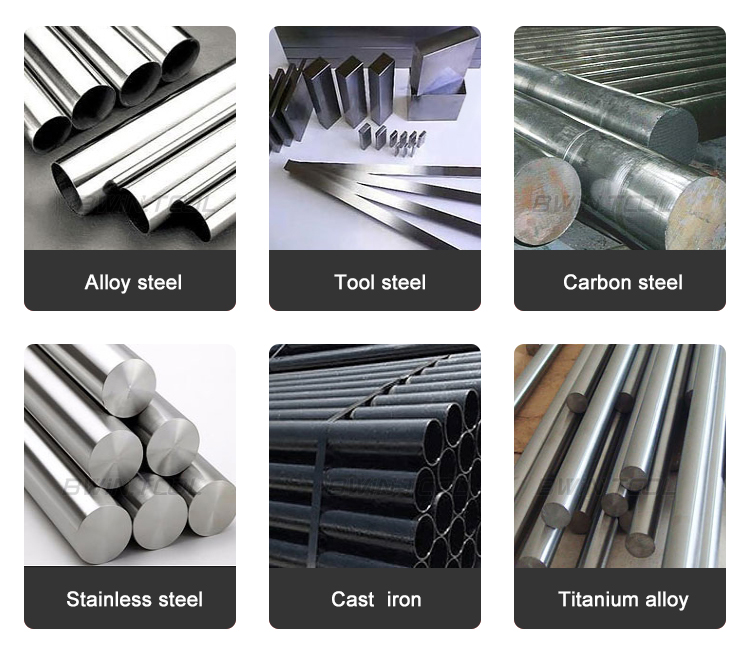

Our tungsten carbide inserts could to be processed Alloy steel, Tool steel, carbon steel, stainless steel, Cast iron and Titanium alloy. Working material as following: