Shenzhen Bwin Precision Tools Co., Ltd. |

|

Quick Detail:

Description:

Specifications:

| Brand | BWIN |

| Model | 16ER/16IR 16UN |

| Color | Black/Yellow |

| Workpiece | Stainless steel/Cast iron/Steel |

| Type | Metal CNC Carbide Lathe Cutting Tool |

| Material | CNC Carbide Threading Insert |

| Processing Type | Medium Cutting |

| Feature | Good red hardness |

| High bending strength | |

| Thermal shock | |

| Efficient processing | |

| Efficient processing | |

| Standard | ISO |

| Quantity | 10pcs/box |

| Weight | 0.015kg |

| Package | Plastic Box |

| Customized Support | OEM, ODM |

Lead Time:

| antity(pieces) | 1 - 3000 | >3000 |

| Lead time (days) | 7 | To be negotiated |

Notice:

Carbide thread insert is characterized by large cutting resistance, easy tool vibration, difficult chip removal, difficult cooling, and complex programming. Therefore, the following matters should be paid attention to during processing:

Applications:

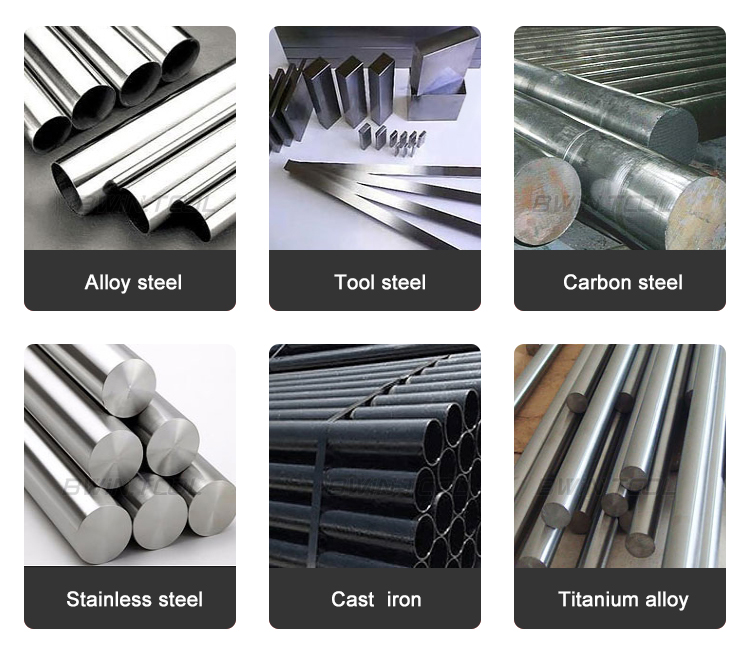

Our carbide threading insert could to be processed Alloy steel, Tool steel, carbon steel, stainless steel, Cast iron and Titanium alloy. Working material as following:

Advantages:

1. Honest merchants, reasonable price and quality assurance

2. Large inventory, sufficient supply and high cost performance

3. Customer service responds in time and delivers goods quickly

4. Provide after-sale guarantee to make your after-sale service free

Q1. Can you give me a carbide threading insert sample?

A: Yes, we welcome ordering samples to test and check the quality. Mixed samples are acceptable.

Q2. How about the delivery date?

A: Sample preparation lasts for 3-5 days and batch production lasts for 8-10 working days.

Q3. Does your company have a minimum order quantity limit for cemented carbide threading insert?

A: The minimum order quantity is low, and one sample can be provided for inspection.

Q4. How do you ship the goods and how long will it take to arrive?

A: Ship via DHL, UPS, FedEx or TNT. It takes 3-5 days to arrive. Air and sea transportation are also optional.

Q5. How to continue to order cemented carbide threading insert?

A: First let us know your request or application.

Secondly, we will quote according to your requirements or suggestions.

Third, the customer confirms the sample and makes a deposit for the formal order.

Fourth, we arrange production.

Q6. Can I print my logo on cemented carbide insert products?

A: Yes. Please inform us formally before production.