Shenzhen Bwin Precision Tools Co., Ltd. |

|

Quick Detail:

Description:

Specifications:

| Brand | BWIN |

| Model | Wcmx030208 Wcmx040208 |

| Color | Fuchsia/Black |

| Workpiece | Stainless steel/Steel |

| Type | Tungsten CNC Carbide U Drill Insert |

| Material | Tungsten U Drilling Insert |

| Processing | Medium Cutting |

| Feature | Precision machining |

| High quality coating | |

| Sharp and wear-resistant | |

| Stable performance | |

| High efficiency | |

| Standard | ISO |

| Quantity | 10pcs/box |

| Weight | 0.015kg |

| Package | Plastic Box |

| Customized | OEM, ODM |

Lead Time:

| antity(pieces) | 1 - 3000 | >3000 |

| Lead time (days) | 7 | To be negotiated |

Notice:

Applications:

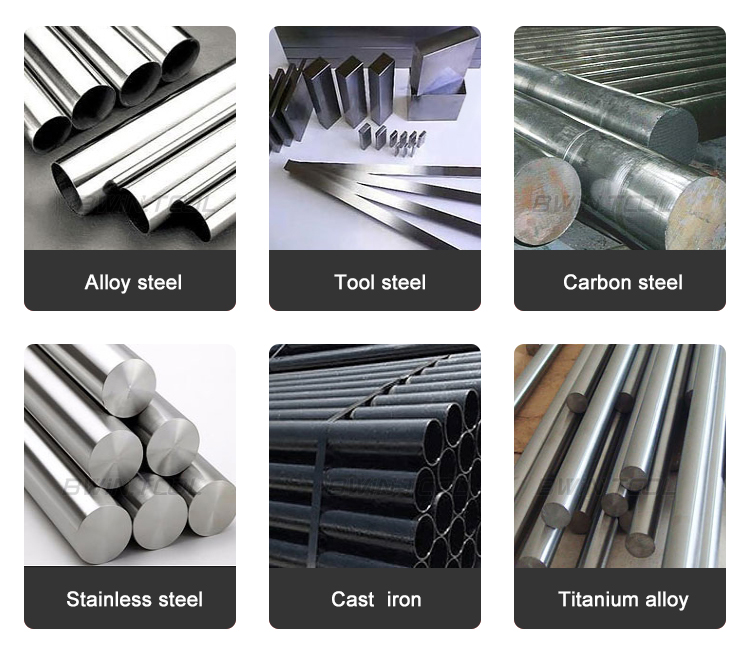

Our CNC carbide U drill insert could to be processed Alloy steel, Tool steel, carbon steel, stainless steel, Cast iron and Titanium alloy. Working material as following:

Advantage

1. Distribution and wholesale, complete in variety

Large quantity is preferred, product specifications are complete, and the pattern is subdivided into processing technology levels to meet your processing needs for different angles and different workpieces;

2. Carefully selected materials with reliable quality

Every detail has been strictly checked, and better products have been meticulously created. They are cheap, stable, durable and have a long service life

3. Sufficient supply and large inventory

We have our own factory, with a large amount of inventory to provide you with sufficient supply, so you don't need to worry about the shortage crisis, so that you can use it with confidence. Support customization, large quantity and price can be discussed, welcome to consult.

4. After sales service

We have a complete after-sales system. Cooperation is not the end, it is the beginning. If you have after-sales problems, please contact us at any time, and we will solve them for you as soon as possible.

1. Flank Wear? Higher cutting resistance,Notch wear on flank,Poor

roughness of surface, or deterioration of accuracy.

Soft grades,Excessive cutting speed,Small flank angle,Low feed.

Select a higher,wear-resistant grade,Reduce cutting speed,Increase

flank angle,Increase feed.

2. Crater Wear? Uncontrolled chip,Poor surface quality,when

finishing High speed processing carbon steel

Soft grades,Excessive cutting speed,Excessive feed,The strength of

chip breaker Insufficiet.

Change to a higher wear-resistant grade,Reduce cutting speed,Reduce

feed,Select a higher strength chip breaker.

3. Chipping? Sudden fracture of cutting edge(rake face and

flank),Instability insert life

Toughness insufficient,Excessive feed rate,Strength of cutting edge

insufficient,Instability of the tool.

Select a tougher grade,Decrease feed rate,Increase honing of

cutting edge(chamfering to rounding),Increase the stability and

setting angle

4. Insert Fracture? Cutting resistance increased Poor surface

roughness.

Toughness insufficient,Excessive feed rate,Strength of cutting edge

insufficient,Instability of the tool.

Select a tougher grade,Decrease feed rate,Increase honing of

cutting edge(chamfering to rounding),Increase the stability and

setting angle.

5. Plastic Deformation? Variation of dimension Nose wear,cutting

edge drape or passivating.when processing alloy steel Poor surface

roughness

Soft grade,Excessive cutting speed,Excessive cutting depth and feed

rate,Overheat on cutting edge.

Select a higher red hardness cutting material,Decrease cutting

speed,Decrease cutting depth and feed rate,Select a higher thermal

conductivity cutting material(CVD+sufficient coolant).

6. Build-Up-Edge? Workpiece dissove with Cutting edge Poor surface

roughness when finishing,Cutting resistance increased,Cutting soft

materials.

Cutting speed too low,Cutting edge obtuse,Unsuitable tool material.

Increase cutting speed,Increase rake angle,Select small sticking

force.