Shenzhen Bwin Precision Tools Co., Ltd. |

|

Quick Detail:

Description:

Specifications:

| Brand | BWIN |

| Model | HSS Drill Bits For Machine Tools |

| Workpiece | Cast iron/Steel /Stainless steel /Aluminum /copper |

| Type | Nail HSS Drill Bit |

| Material | High Speed Steel |

| Processing Type | Medium Cutting |

| Feature | High hardness |

| Wear resistance | |

| Alignment | |

| Good chip removal | |

| High efficiency | |

| Standard | ISO |

| Quantity | 1pcs/box |

| Surface Finish | Black Oxide (Black White, Gray Bright) |

| Package | Plastic Box |

| Customized Support | OEM, ODM |

Lead Time:

| antity(pieces) | 1 - 3000 | >3000 |

| Lead time (days) | 7 | To be negotiated |

Parameter:

3D/5D External Cooling Cutting Parameters

| Processed

| Mild steel HB≤180 | Prehardened steel -40HRC | stainless steel | cast iron | aluminium alloy | heat-resisting alloy | ||||||

| vc/(m/min) | 60~120m/min | 40~70m/min | 25~40m/min | 60~120m/min | 60~14m/min | 15~25m/min | ||||||

| D(mm) | N (min) | F (mm/r) | N (min) | F (mm/r) | N (min) | F (mm/r) | N (min) | F (mm/r) | N (min) | F (mm/r) | N (min) | F (mm/r) |

| 2 | 14000 | 0.06~ 0.08 | 9500 | 0.06~ 0.08 | 5500 | 0.02~ 0.05 | 14000 | 0.06~ 0.08 | 16000 | 0.06~ 0.08 | 3200 | 0.02~ 0.04 |

| 3 | 9500 | 0.09~ 0.12 | 6300 | 0.09~ 0.12 | 3700 | 0.03~ 0.07 | 9500 | 0.09~ 0.12 | 10600 | 0.09~ 0.12 | 1200 | 0.03~ 0.06 |

| 4 | 7000 | 0.10~ 0.15 | 4700 | 0.10~ 0.15 | 2700 | 0.04~ 0.08 | 7000 | 0.10~ 0.15 | 8000 | 0.10~ 0.15 | 1600 | 0.04~ 0.07 |

| 5 | 5700 | 0.12~ 0.18 | 3800 | 0.12~ 0.18 | 2200 | 0.05~ 0.10 | 5700 | 0.12~ 0.18 | 6400 | 0.12~ 0.18 | 1250 | 0.05~ 0.09 |

| 6 | 4700 | 0.14~ 0.20 | 3100 | 0.14~ 0.20 | 1850 | 0.06~ 0.12 | 4700 | 0.14~ 0.20 | 5300 | 0.14~ 0.20 | 1050 | 0.06~ 0.11 |

| 8 | 3600 | 0.16~ 0.24 | 2400 | 0.16~ 0.24 | 1400 | 0.08~ 0.16 | 3600 | 0.16~ 0.24 | 4000 | 0.16~ 0.24 | 800 | 0.08~ 0.14 |

| 10 | 2800 | 0.18~ 0.27 | 1900 | 0.18~ 0.27 | 1100 | 0.18~ 0.27 | 2800 | 0.27~ 0.18 | 3200 | 0.18~ 0.27 | 600 | 0.10~ 0.16 |

| 12 | 2400 | 0.20~ 0.3 | 1600 | 0.20~ 0.3 | 930 | 0.12~ 0.20 | 2400 | 0.20~ 0.3 | 2700 | 0.20~ 0.3 | 500 | 0.12~ 0.18 |

| 14 | 2100 | 0.22~ 0.35 | 1400 | 0.22~ 0.35 | 800 | 0.13~ 0.22 | 2100 | 0.22~ 0.35 | 2300 | 0.22~ 0.35 | 450 | 0.13~ 0.2 |

| 16 | 1800 | 0.25~ 0.36 | 1200 | 0.25~ 0.36 | 700 | 0.25~ 0.36 | 1800 | 0.25~ 0.36 | 2000 | 0.25~ 0.36 | 400 | 0.14~ 0.23 |

| 18 | 1600 | 0.28~ 0.38 | 1100 | 0.28~ 0.38 | 620 | 0.28~ 0.38 | 1600 | 0.28~ 0.38 | 1800 | 0.28~ 0.38 | 350 | 0.15~ 0.25 |

| 20 | 1400 | 0.30~ 0.4 | 950 | 0.30~ 0.4 | 550 | 0.30~ 0.4 | 1400 | 0.30~ 0.4 | 1600 | 0.30~ 0.4 | 320 | 0.16~ 0.28 |

3D/5D internal cooling cutting parameter

| Processed materials

| Mild steel HB≤180 | Prehardened steel -40HRC | stainless steel | cast iron | aluminium alloy | heat-resisting alloy | ||||||

| vc/(m/min) | 60~120m/min | 40~70m/min | 25~40m/min | 60~120m/min | 60~14m/min | 15~25m/min | ||||||

| D(mm) | N (min) | F (mm/r) | N (min) | F (mm/r) | N (min) | F (mm/r) | N (min) | F (mm/r) | N (min) | F (mm/r) | N (min) | F (mm/r) |

| 3 | 12700 | 0.09~ 0.12 | 7400 | 0.09~ 0.12 | 6300 | 0.03~ 0.07 | 12700 | 0.09~ 0.12 | 15000 | 0.09~ 0.12 | 1200 | 0.03~ 0.06 |

| 4 | 9600 | 0.10~ 0.15 | 5600 | 0.10~ 0.15 | 4700 | 0.04~ 0.08 | 9600 | 0.10~ 0.15 | 11000 | 0.10~ 0.15 | 1600 | 0.04~ 0.07 |

| 5 | 7600 | 0.12~ 0.18 | 4500 | 0.12~ 0.18 | 3800 | 0.05~ 0.10 | 7600 | 0.12~ 0.18 | 9000 | 0.12~ 0.18 | 1250 | 0.05~ 0.09 |

| 6 | 6400 | 0.14~ 0.20 | 3700 | 0.14~ 0.20 | 3200 | 0.06~ 0.12 | 6400 | 0.14~ 0.20 | 7400 | 0.14~ 0.20 | 1050 | 0.06~ 0.11 |

| 8 | 4800 | 0.16~ 0.24 | 2800 | 0.16~ 0.24 | 2400 | 0.08~ 0.16 | 4800 | 0.16~ 0.24 | 5600 | 0.16~ 0.24 | 800 | 0.08~ 0.14 |

| 10 | 3800 | 0.18~ 0.27 | 2200 | 0.18~ 0.27 | 1900 | 0.18~ 0.27 | 3800 | 0.27~ 0.18 | 4500 | 0.18~ 0.27 | 600 | 0.10~ 0.16 |

| 12 | 3200 | 0.20~ 0.3 | 1900 | 0.20~ 0.3 | 1600 | 0.12~ 0.20 | 3200 | 0.20~ 0.3 | 3700 | 0.20~ 0.3 | 500 | 0.12~ 0.18 |

| 14 | 2700 | 0.22~ 0.35 | 1600 | 0.22~ 0.35 | 1350 | 0.13~ 0.22 | 2700 | 0.22~ 0.35 | 3200 | 0.22~ 0.35 | 450 | 0.13~ 0.2 |

| 16 | 2400 | 0.25~ 0.36 | 1400 | 0.25~ 0.36 | 1200 | 0.14~ 0.25 | 2400 | 0.25~ 0.36 | 2800 | 0.25~ 0.36 | 400 | 0.14~ 0.23 |

| 18 | 2100 | 0.28~ 0.38 | 1200 | 0.28~ 0.38 | 1050 | 0.15~ 0.28 | 2100 | 0.28~ 0.38 | 2500 | 0.28~ 0.38 | 350 | 0.15~ 0.25 |

| 20 | 1900 | 0.30~ 0.4 | 1100 | 0.30~ 0.4 | 950 | 0.16~ 0.30 | 1900 | 0.30~ 0.4 | 2300 | 0.30~ 0.4 | 320 | 0.16~ 0.28 |

Notice:

Applications:

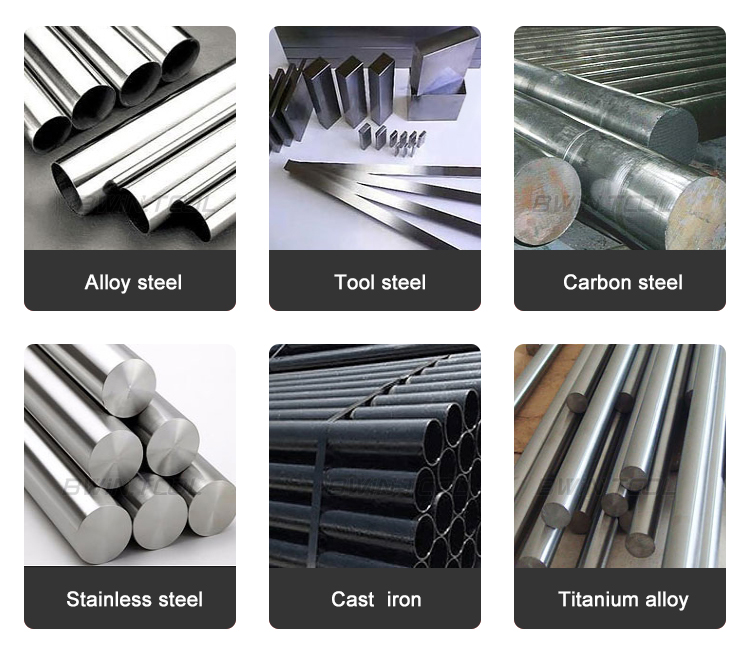

Our HSS drill bits could to be processed Alloy steel, Tool steel, carbon steel, stainless steel, Cast iron and Titanium alloy. Working material as following:

FAQ

Q1. Excessive aperture

Reasons: 1. The cemented carbide drill is not well clamped, and the runout of the spindle itself is too large

2. Asymmetrical sharp angle, excessive blade height difference, eccentric cross blade

Solution: 1. select high-quality tool handle and fixture, calibrate the spindle, and carefully measure and adjust each time the drill is clamped

2. Re sharpen and correct, and check the accuracy after sharpening

Q2. Poor consistency of aperture

Reasons: 1. Asymmetrical sharp angle, too large difference in blade height, eccentric transverse edge, and too much wear on edge surface

2. The cemented carbide drill bit is not properly clamped, the runout of the spindle itself is too large, and the workpiece is not firmly clamped

3. Excessive feed speed

4. Insufficient cutting fluid supply

Solution: 1. Re sharpen the drill and check the accuracy after sharpening

2. Select a good tool handle and fixture, calibrate the spindle, and carefully measure and adjust each time the drill is clamped

3. Reduce the feed speed of cemented carbide drill

4. Change the cutting fluid supply method and increase the flow).

Q3. Poor hole straightness and verticality

Reasons: 1. Excessive tool wear

2. Asymmetrical sharp angle, excessive blade height difference, eccentric cross blade

3. Insufficient rigidity

4. Uneven cutting plane

Solution: 1. Re sharpen

2. Re sharpen and correct, and check the accuracy after sharpening

3. Improve the rigidity of machine tools, jigs, cemented carbide drills, etc

4. Check the levelness of the pre machined surface

Q4. Poor hole location and poor consistency of center distance

Reasons: 1. The drill bit is not properly clamped, and the spindle itself has excessive runout

2. Deviation during cutting

3. Machine tool accuracy loss

4. The centering effect of cemented carbide bit is poor, and the cross edge is eccentric

Solution: 1. select a good tool handle and fixture, calibrate the spindle, and carefully measure and adjust each time the drill is clamped

2. Improve the rigidity of the cutter and machine tool, and the rigidity of the workpiece and fixture. Use the drill type with good cutting performance, and check the levelness of the cutting surface

3. Check the accuracy of the machine tool

4. Re sharpen the carbide bit, and check the accuracy after sharpening