TOBO STEEL GROUP CHINA |

|

Verified Suppliers

|

|

Stainless Steel 304 / 316L Pipe Elbows 90Degree LR Mirror Finished

|  |  |

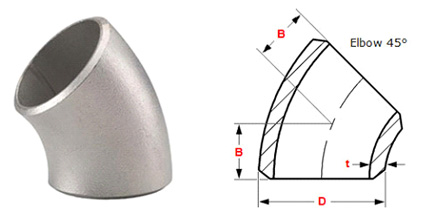

| 45 degree | 90 degree | 180 degree |

a comparison the thickness of our 8 gauge forged stainless elbows compared to the average exhaust manifold material- 16 gauge 304 tube

cross sectioned tube that was purged to show the exact inner surface of the weld, and zero chance of cracking

Size:

Seamless elbow: 1/2"~24"DN15~DN600

Welding elbow: 6"~72" DN150~DN1800

Wall Thickness :

sch10, sch20, sch30, std, sch40, sch60, xs, sch80, sch100, sch120,

sch140, sch160, xxs, sch5s, sch20s, sch40s, sch80s

Max wall thickness: 200mm

Materials

SS304, SS316L

Finishment :

acid clean, line polish, mirror polish, sandblast.

Standards

GB/T12459-2005 GB/T13401-2005 GB/T10752-2005 SH/T3408-1996

SH/T3409-1996

SY/T0609-2006 SY/T0518-2002 SY/T0510-1998

DL/T695-1999 GD2000 GD87-1101

HG/T21635-1987 HG/T21631-1990

ASME B16.9-2007 ASME B16.25-2007

MSS SP 75-2008 MSS SP 43-2008

CSA Z245.11-05-2005

EN10253-1-1999 EN10253-2-2007 EN10253-3-2008 EN10253-4-2008

DIN2605-1-1992 DIN2605-2-1995

BS1640-1-1962 BS1640-2-1962 BS1640-3-1968 BS1640-4-1968

BS1965-1-1963

GOST17375-2001

AFNOR NF A 49-289-1990 AFNOR NF A 49-170-1-1999 AFNOR NF A

49-170-2-2009 AFNOR NF A 49-170-3-2009 AFNOR NF A 49-170-4-2009

ISO3419-1981 ISO5251-1981

JIS B2311-2009 JIS B2312-2009 JIS B2313-2009

Industrial Processes

Bending, squeezing, pressing, forging, machining and more

Industries Served

Our pipe elbows are widely used in many industries, such as power

generation, petroleum, natural gas, chemicals, shipbuilding,

heating, papermaking, metallurgy and so on.

| NPS | O.D. D | 90 degrees Long Radius Center-to-End A | 45 degrees Long Radius Center-to-End B | 90 degrees 3D Center-to-End A | 45 degrees 3D Center-to-End B |

| 1/2 | 21.3 | 38 | 16 | - | - |

| 3/4 | 26.7 | 38 | 19 | 57 | 24 |

| 1 | 33.4 | 38 | 22 | 76 | 31 |

| 1¼ | 42.2 | 48 | 25 | 95 | 39 |

| 1½ | 48.3 | 57 | 29 | 114 | 47 |

| 2 | 60.3 | 76 | 35 | 152 | 63 |

| 2½ | 73 | 95 | 44 | 190 | 79 |

| 3 | 88.9 | 114 | 51 | 229 | 95 |

| 3½ | 101.6 | 133 | 57 | 267 | 111 |

| 4 | 114.3 | 152 | 64 | 305 | 127 |

| 5 | 141.3 | 190 | 79 | 381 | 157 |

| 6 | 168.3 | 229 | 95 | 457 | 189 |

| 8 | 219.1 | 305 | 127 | 610 | 252 |

| 10 | 273 | 381 | 159 | 762 | 316 |

| 12 | 323.8 | 457 | 190 | 914 | 378 |

| 14 | 355.6 | 533 | 222 | 1067 | 441 |

| 16 | 406.4 | 610 | 254 | 1219 | 505 |

| 18 | 457 | 686 | 286 | 1372 | 568 |

| 20 | 508 | 762 | 318 | 1524 | 632 |

| 22 | 559 | 838 | 343 | 1676 | 694 |

| 24 | 610 | 914 | 381 | 1829 | 757 |

| 26 | 660 | 991 | 406 | 1981 | 821 |

| 28 | 711 | 1067 | 438 | 2134 | 883 |

| 30 | 762 | 1143 | 470 | 2286 | 964 |

| 32 | 813 | 1219 | 502 | 2438 | 1010 |

| 34 | 864 | 1295 | 533 | 2591 | 1073 |

| 36 | 914 | 1372 | 565 | 2743 | 1135 |

| 38 | 965 | 1448 | 600 | 2896 | 1200 |

| 40 | 1016 | 1524 | 632 | 3048 | 1264 |

| 42 | 1067 | 1600 | 660 | 3200 | 1326 |

| 44 | 1118 | 1676 | 695 | 3353 | 1389 |

| 46 | 1168 | 1753 | 727 | 3505 | 1453 |

| 48 | 1219 | 1829 | 759 | 3658 | 1516 |

| DIMENSIONAL TOLERANCES - ELBOWS | |||||||

| For all fittings | Elbows 90/45 deg | 180° Returns | |||||

| Nominal Pipe Size (NPS) | Outside Ø at Bevel | Inside Ø at End | Wall Thickness t / t1 | Center to End Dim. A-B-C-M | Center to Center Dim. O | Back to Face Dim. K | Align- ment of Ends U |

| 1/2 a 2 1/2 | 1 | 0,8 | Not | 2 | 7 | 7 | 1 |

| 3 a 3 1/2 | 1 | 1,6 | less | 2 | 7 | 7 | 1 |

| 4 | +2 -1 | 1,6 | than | 2 | 7 | 7 | 1 |

| 5 a 6 | +3 -1 | 1,6 | 87,50% | 2 | 7 | 7 | 1 |

| 8 | 2 | 1,6 | of nominal | 2 | 7 | 7 | 1 |

| 10 | +4 -3 | 3,2 | tickness | 2 | 7 | 7 | 2 |

| 12 a 18 | +4 -3 | 3,2 | 3 | 10 | 7 | 2 | |

| 20 a 24 | +6 -5 | 4,8 | 3 | 10 | 7 | 2 | |

| 26 a 30 | +7 -5 | 4,8 | 3 | ..... | ..... | ..... | |

| 32 a 48 | +7 -5 | 4,8 | 5 | ..... | ..... | ..... | |

| Angularity Tolerances | ||

| ND | Max off angle | Max off plane |

| Q | P | |

| 1/2 a 4 | 1 | 2 |

| 5 a 8 | 2 | 4 |

| 10 a 12 | 3 | 5 |

| 14 a 16 | 3 | 7 |

| 18 a 24 | 4 | 10 |

| 26 a 30 | 5 | 10 |

| 32 a 42 | 5 | 13 |

| 44 a 48 | 5 | 20 |