Active Member

|

[China]

Address: NO 123 Suzhou Dadao East Road Suzhou Jiangsu China

Contact name:Tina

Suzhou Kiande Electric Co.,Ltd. |

|

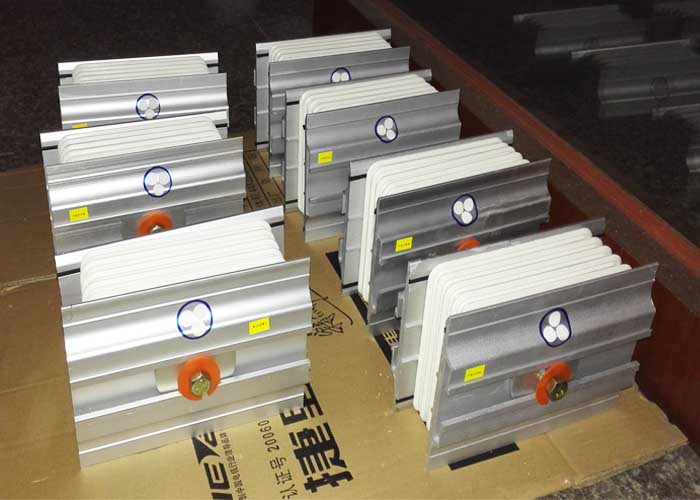

630A Busbar Joint Block for Sandwich Busway System Connection

Busduct joint is used to connect two elements of the busbar systems, it can be fitted or removed in installed condition without removal of the adjacent sections or elements .The torque nut ensures tigthness of joints at desired torque and eleminates the need of torque wrench during installation. Heavy duty side plates and Belleville washers insures uniform distribution of pressure. Joints can be tightened easily with the help of a spanner on one side only.

No. | Parameter |

Product name | Busbar Joint |

Current rating | 400A-4000A |

Material | Copper or aluminum |

Busduct joint

This joint stack design has taken into the consideration of a bigger contact surface of the conductors in order to reduce power loss and improve cooling performance.

Double headed joint bolts together with Belleville washer ensure a sufficient pressure required to secure each joint connection.

The double headed joint bolt is also designed with a specific torque value whereby the outer head of the joint bolt (which acts as

tightness indication) will shear off when it reaches the limit and this will prevent over tightening of the joint section.

Installation Guidence of Busduct Joint

Step1:dentify the correct joint stack (either 4W or 5W) and its

phase orientation before Busduct joint pack installation

Step2: Align and connect both busduct terminal with joint stack connector.

Step3:Joint stack stopper acts a guideline to ensure a full contact surface of the overlapping conductors.

Step4: Tighten the double headed bolt by using socket wrench untile the outer head shear off.

Step5:Place joint pack covers on both sides of the busduct joint section and tighten all the bolts and nuts with socket wrench.