Hubei Yideli Light Industry Technology Co., Ltd. |

|

1.5" SS304 Clamped Rotary Spray Ball For Water Tanks CIP Cleaning Ball Of Brewing Accessories

Stainless steel cleaning standard: DIN, SMS, ISO, IDF, 3A, RJT, DS, BS, BPE, API,JIS,GB material:SUS304, SUS304L, SUS316, SUS316L.

It is widely used in chemical industry, petroleum, electric power, pharmaceutical, beer, food, milk beverage, cosmetics and all kinds of engineering supporting pipelines.Professional production and sales of sanitary centrifugal pump, the health level of CIP return pump, rotor pump, high shear emulsifying machine (intermittent)/pipeline scattered high shear emulsifying machine and ISO, DIN, IDF and 3 grade a standard stainless steel joint, clamp, fast loading of bend and U tube, concentric reducer, tee, ball valve, diaphragm valve, quick quick butterfly valve, sight glasses, manhole covers, microporous membrane cartridge filter and diaphragm pressure gauge, cleaners, breathing apparatus, floor drain fluid equipment such as a full range of pipe fittings.It is widely used in the fields of brewery, dairy, beverage factory, pharmaceutical factory, biological engineering, supporting machinery supplier and so on.The company is responsible for the overall pipeline engineering design and installation business.Specializing in the production of health level and high shear emulsifying machine (intermittent)/pipeline scattered high shear emulsifying machine with the health pumps and high precision health level valve/pipe fittings, the products are widely used in food, pharmaceutical, dairy products, beer, beverage, chemical industry, etc.Comply with GMP, QS, HACCP requirements!

Hygienic level cleaning ball.

1. Grade: SUS304, SUS304L, SUS316, SUS316L.

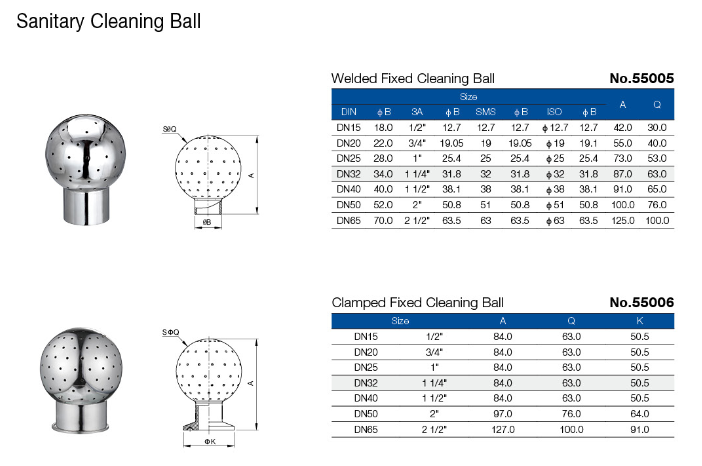

2. Size: DN15 - DN200

3. Type: Triclover, welding, threaded.

4. Standard: DIN/SMS/RJT/ISO

5. Certification: ISO9001, CE, SGS, CTI, ROHS

CAFER sanitary valve cleaning ball.

application

Fixed cleaning ball, rotating cleaning ball, horn type cleaning ball and so on the ball series of products, widely used in food, beverage, wine, dairy products, cosmetic, pharmaceutical, fine chemical industry field, including tanks, reactors, container, etc.

advantages

Meet DIN standards, triple-a standards, SMS standards, ISO/IDF standards and other production standards.

Applicable to different industrial site installation requirements.

Technical parameters

Fixed cleaning ball, rotary cleaning ball, ox horn cleaning ball and other cleaning ball series.

Weight: confirm weight according to specifications.

Lubrication: self-lubrication by cleaning liquid.

Working pressure: 1-3bar.

The highest working temperature: 95 ℃

The highest temperature: 140 ℃

Spray cleaning radius: the maximum effective radius is 2 meters.

Wetting radius: 3 m maximum.

Health grade material: SUS304, SUS316L;Diameter: dn40-50;Connection mode: thread, fast loading, cleaning in various tanks.The main purpose of the stainless steel fixed cleaning ball is to remove all the material accumulated on the tank wall so as to ensure the sterilization of the tank.Should be in the shortest possible time to use the most economic method of cleaning, chemical, power and manpower to achieve this purpose, the company cleaning device series, including fixed wash tank and rotation can washing ball, can match the import of alfa laval, APV, price was only about a third of the import price.Specification: 1-2.1/2;Connection: screw thread, clamp, bolt type;Material: the main purpose of stainless steel 304 and 316L stainless steel rotary cleaning is to remove all the material accumulated on the tank wall so as to ensure the sterilization of the tank.Should be in the shortest possible time to use the most economic method of cleaning, chemical, power and manpower to achieve this purpose, the company cleaning device series, including fixed wash tank and rotation can washing ball, can match the import of alfa laval, APV, price was only about a third of the import price.Gauge: 1-2.1/2;Connect: screw thread, clamp, bolt type;Material: stainless steel 304, 316L stainless steel rotary washer (double loop horn type drive washer)- health level 1, effective cleaning of 4.5m diameter containers;2. Maximum cleaning efficiency, low water consumption, energy consumption and chemical dosage;3. Sanitary structure: self-lubrication with cleaning fluid;4. The connection mode is threaded fastening or welding;5. Can wash cans in all directions at any Angle.Specification: 1-2;Connection: thread type, bolt type;Material: stainless steel 304, 316L.