Hubei Yideli Light Industry Technology Co., Ltd. |

|

5000L 4 Vessel Brewhouse Beer Making Machine Fermentation Tank With Dimple Plate Jacket

1. beer brewing equipment product brief instruction

This set of beer brewing equipment is generally adopted by household use beer brewing or laboratory use equipment,but also a good choice for resturant,barbecue and other small business;

The apperance of the Mash tun &fermenter tank can be made into red copper kinds,paractical and a kind of decoration;

2. beer brewing equipment product instructure

The complete set of beer equipment Includes Malt mill device, Saccharification system,Fermenting system,

CIP system, Refrigerator units,Electrical control cabinet and assorted pumps,valves etc.

We also can offer Turnkey Brewery Plant with filtering machine, filling line or bright beer tank if needed;

| Production Capacity | 100L/day | 200L/day | 300L/day | 500L/day | 1000L/day | 2000L/day |

| Floor space | ≥15 M2 | ≥25 M2 | ≥35 M2 | ≥50 M2 | ≥80 M2 | ≥120 M2 |

| Total power | 12 KW | 12 KW | 12 KW | 15/36 KW | 22/72 KW | 31/144 KW |

| Consumption of water(Max) | 0.2 M3/H | 0.4 M3/H | 0.5 M3/H | 1.0 M3/H | 1.5 M3/H | 2.0 M3/H |

| Total water consumption per day | 0.5 M3/D | 1.0 M3/D | 1.5 M3/D | 2.5 M3/D | 5.0 M3/D | 10 M3/D |

| Consumption of Malt | 20 KG | 40 KG | 60 KG | 100 KG | 200 KG | 400 KG |

Brewhouse:

3/4 vessels is also available if pub brewery space and operation needed

Hot water tank optional

Heating method:

Electricity heating/steam heating(electricity/LPG/diesel oil/nautral gas)

Material:

Interior stainless steel 2.5~3.0mm, exterior stainless steel/luxury red copper cladding 1.5~2.0mm

High quality materials

The raw materials is SUS304 and SUS316, which require materials quality certificate.

We’ll test the materials quality using chemical agent when we receive the materials.

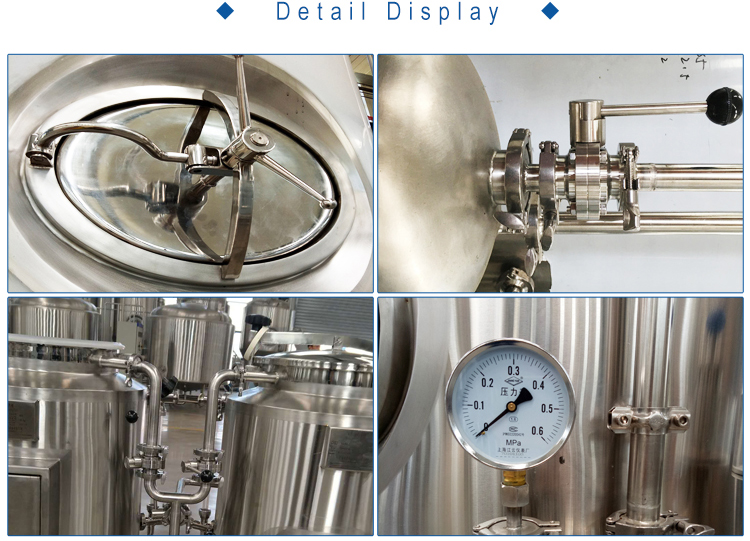

Excellent appearance

The polishing standard of welding seam is 240 um, 60mm width. All of connection required

turn up workmanship and all of welding seam required polishing, which is more smooth

tank surface. We’re very serious about the excellent appearance of tanks.

Insulation layer:

Polyurethane or rockwool, thickness 80~100mm

The Standard Of Tank:

We use plasma torch to cut the materials on the soft carpet, avoid to damaging the surface of

stainless steel, and then we adopt double argon protection welding

Volume: Working volume and 20%-30%additional space.

Inner Shell: SUS304 materials, thickness 3mm, acid washing and

passivation treatment, furthermore,polishing and mirror treatment are workable with different cost.

All of the inner surface connection using turnup workmanship and polishing round.

The normal pressure is 0.2Mpa, maximum test pressure is 0.4Mpa.

Cladding: SUS304, 2mmthickness, welding seam polishing, 60mm width.

All of the welding connection polishing treatment, more smooth

Polyurethane insulation and stainless steel cooling jacket, 60 or 72 degree bottom cone;

Single tank, single control.

Cooling: double stage cooling, cooling system for both heat exchanger and fermenter

Cleaning: 50L/100L/150L CIP cleaning, movable with wheel

BEER BREWING SYSTEM CONFIGURATION

| No. | Beer System | Components | Specification /Feature |

| 01 | Mill System | Miller | Double Roller,Noise<60db |

| 02 | Heating System | Boiler (steam heating) | Electric,Gas,Oil,Coal Type/CE certification |

| 03 | Brewhouse System | Mash/Lauter tun | Mashing Process:Decoction.Infusion.Multi-step infusion Heating source:Steam,Electric,Gas SUS304/Red copper |

| Brew Kettle/ Whirlpool Tank | |||

| Hot Water Tank | |||

| Heat exchanger | Stainless steel plate | ||

| 04 | Fermentation System | Fermentation Tank Bright Beer Tank | Top manway/Side manway Drying hop port to brew IPA Dimple Plate Cooling jacket Carbonation port to fill CO2 |

| Yeast Adding Tank | SUS304 Stainless Steel | ||

| 05 | Cooling System | Glycol Water tank | Equiped with PU level indicator |

| Chiller | UL/CE certified electric elements,Copeland compressor | ||

| Pump | |||

| 06 | Cleaning System | Disinfection Tank | SUS304 full welded |

| Alkali Tank | |||

| Pump | |||

| 07 | Control System | Control Cabinet | Manual/Semi-automatic/Automatic |

| 08 | Optional | Auger System | |

| Grain Case | |||

| Grist Hydrator | |||

| Piping flow panel for Brewhouse | |||

| Brewhouse Separate PLC Controller | |||

| Support equipments | |||