|

|

[China]

Trade Verify

Address: Address: N0.1, Dongli Road, Donglai, Zhangjiagang City, Jiangsu Province, China

Contact name:Sandy Chen

Zhangjiagang HuaDong Boiler Co., Ltd. |

|

Verified Suppliers

|

|

Spiral Fin Heat Exchanger Tubes - Long Service Life

Typical materials for economizer tubes?

Carbon steel (SA-210C) for ≤300°C, alloy steel (SA-213 T11) for higher temps.

Product Description

Economizer coils are used in downstream of Boiler bank to preheat the feed water absorbing heat from hot exhaust gases. Economizers are always water tube type. Economizers have different types of Tubes depending upon the application. Bare tubes in Economizers are widely used in Industrial boilers and for applications like Heat recovery boilers in Sulfuric acid plants, gilled tubes are employed. Finned tubes are popular in HRSG applications. Feed water can be heated up to a level about 20 - 30 C below saturation temperature of the boiler.

Specifications

| Description | Economizer |

| Material | Alloy steel, Carbon steel, SA210C ,SA213T22, etc. |

| Material standard | ASTM, EN or ISO etc. |

| Dimension | Customization |

| Weight | Min: 10 ton Max.:1000 ton |

| Smelting Process: | EF+LF + VD |

| Process | Material→Ingot → Hot/Cold-Rolling→ Heat treatment (Normalizing+ tempering) → Inspection →rough machining→UT →2nd Heat treatment →finishing machining →Inspection |

| UT standard | ASTM A388 or EN10228, etc |

Application

During boiler operation in typical commercial and industrial applications, approximately 10-20% of the heating value of fuel is expelled with the stack gases to the atmosphere. Stack economizers are designed to recover significant amounts of this stack gas energy loss, thereby vastly improving boiler system efficiency. There are several considerations when selecting an economizer:

• Gas-side Pressure Drop. Added back-pressure on the boiler stack affects the combustion air fan throughput capability. The economizer and combustion air fan(s) must be sized properly in order to assure a suitable system operation and capacity.

• Feedwater Temperature. The feedwater to the economizer must be deaerated and the temperature setpoint minimally at 220oF to prevent tube corrosion.

• Water-side Pressure Drop. Feedwater pumps must be sized to accommodate the economizer pressure drop. Additionally, a continuous modulating feedwater system is required to ensure proper flow rates through the economizer.

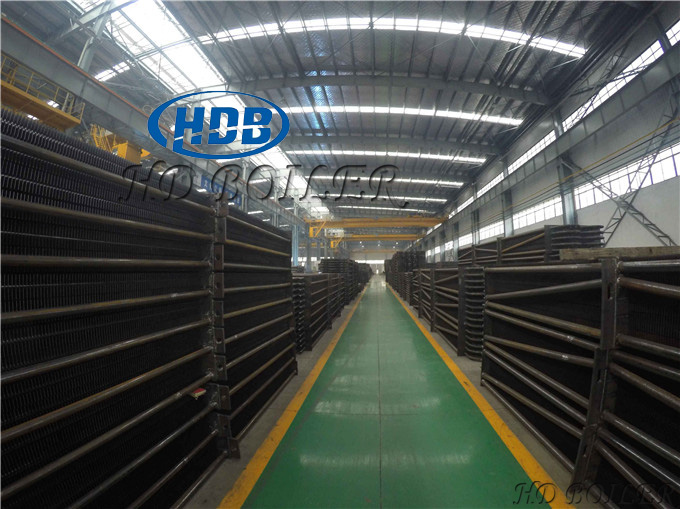

Economizer Workshop

Certificate

Company Introduction

Established in 1985,Zhangjiagang Hua Dong Boiler Co.,Ltd.(trading as HD Boiler),produces power plant; industrial; waste heat; waste incineration; biomass; organic heat carrier and electric steam boilers. Coupled with a comprehensive range of heating surfaces, HD Boiler brings to the market a unique service including boiler design , fabrication, installation, maintenance and replacement of boiler pressure parts.