Jiaxing Jingkai Qixing Machinery Manufacturing Factory |

|

Verified Suppliers

|

|

Blister Machine for Food Container Making Disposable Biodegradable

Blister Machine for Food Container Plate Bowl Box Tray Equipment Eco Friendly Disposable 100% Biodegradable Compostable Food Container Making Machine Production Line

Product Description

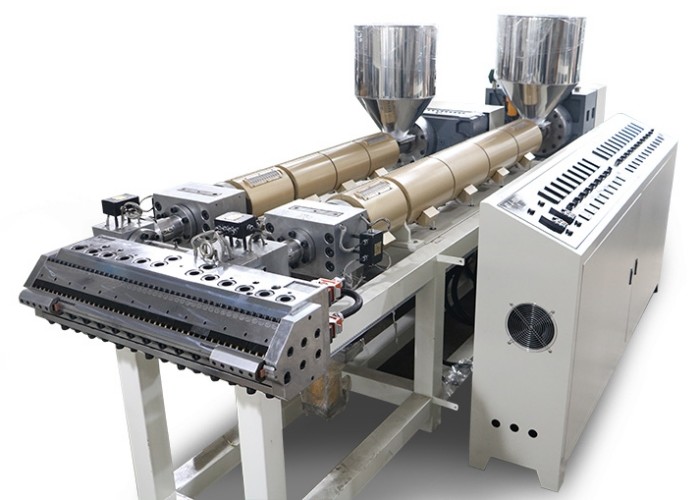

Qixing blister machines (sheet extrusion and blister forming all in one machine) produce a wide variety of packaging types, e.g. trays, containers, hinged boxes, food boxes, plates, bowls, blisters, lids, technical applications, and much more.

The machine connects the extruder with vacuum blister forming machine in one line, and completes all the steps of sheet extrusion and blister forming in one stop, for plastic vacuum products or disposable degradable material products like meal lunch boxes, Burger Box, biscuit trays, bowls, plates, etc., one time heating only, save power and labor cost.

Product Advantages

• High Automation and Easy Operation

Two workers are able to operate the full line each shift. One worker for packing and one for side material re-usage, saves labor costs.

• Cut costs

Sheet extrusion and blister forming all in one machine, that can produce products directly from raw material pellets (including leftover materials, fillers, etc.), with one step in place to complete the extrusion sheet and plastic molding all the processing processes, which may be the equipment with the least investment, the lowest production cost and the highest production efficiency.

• Increase productivity

Our fully automatic production line Integrates extrusion, forming, cutting, stacking and counting, which can bring you more productivity.

• Low Machinery Investment

Each line comes with all associated equipment that clients need to produce products: sheet extruding machine, forming machine, automatic punching machine and cutting machine, one set of customized mold and punching knife.

• Low Energy Consumption

The sheet extruding machine produces sheets directly for product forming and punching. one-time heating only, No secondary heating requires, saves power.

• Adapt Multi-Material

PP, PS, PE, EVOH, PLA, PBAT, plant straw, rice husk, rice bran, bamboo powder, starch and other compostable plant fiber.

• Multi-Application

By changing mold, the machine line is able to produce takeaway boxes, fast food boxes, burger boxes, cake box, bread box, sandwich box, various food containers, clamshell boxes, takeout boxes, fruit and vegetable packaging boxes, supermarket food tray, bowl, plates, etc. All molds can be customized according to the client's needs.

• Wide range of applications

This machine is particularly advantageous for food lunch box products, and can also be widely used in the production of food, electronics, toys, hardware and other packaging products, as well as the inner tray of industrial packaging products.

• Durable and Reliable

The machine line is able to be running 24 hours without problem, Only Requires basic maintenance.

• No material wastage

Side material can be smashed and re-mixed to be used again. There is no material wastage, no gas pollution, and no water pollution during the production process.

• Save money

The machine reduces investment by about 50%, saving 30% of electricity, improving efficiency by 30%, reducing labor intensity, and enhancing economic benefits.

2 - 5 Compartment Tray With Lid

Scope of Application

Our machines are suitable for the following materials :

1. Thermoplastics: PP, PS, PE, EVOH, etc.

2. Thermoplastic biodegradable plastics: PBAT and PLA, etc.

3. Bio-based degradable environmentally friendly materials, fully biodegradable plant fiber materials: grain fiber, corn starch, plant straw, rice husk, rice bran, bamboo powder, wood powder, bagasse, etc.

4. Bio-based composite materials, biodegradable plant fiber blend materials: talcum powder, calcium carbonate, etc.

5. Multilayered materials, Mineral-filled materials.

Our machines are not suitable for the following materials : PET, PVC, ABS

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: Do you accept customized orders?

A: Yes, we do. ODM/OEM business partner will be warmly welcome.

Q: What is your MOQ?

A: We accepts 1 unit as trial order.

Q: What's the payment terms? / Q: What are your payment methods?

A: Payment<=2000USD, 100% in advance. Payment>=2000USD.

T/T, 30% in advance, 70% balance before delivery(Most of customers choose).

Western Union(for small amount only).

XTransfer(for small amount only).