Active Member

|

[China]

Address: No.16 Jinggui West Road , Hudai Industrial Park, Wuxi, China

Contact name:Odelia Wu

Wuxi BioCell Environmental Technology Co., Ltd. |

Screw Filter Press Machine For Treating Sludge Dewatering

Features Of Sludge Dewatering Machine

Parameters

| Model | DS Standard Capacity(kg/h) | Sludge Treatment Capacity(m³/h) | ||||||

| Low Concentration | High Concentration | 2000mg/L | 4000mg/L | 10000mg/L | 20000mg/L | 25000mg/L | 50000mg/L | |

| MDS101 | 3 | 6 | 1.5 | 0.75 | 0.6 | 0.3 | 0.24 | 0.12 |

| MDS131 | 6 | 12 | 3 | 1.5 | 1.2 | 0.6 | 0.48 | 0.24 |

| MDS132 | 12 | 24 | 6 | 3 | 2.4 | 1.2 | 0.96 | 0.48 |

| MDS201 | 12 | 20 | 6 | 3 | 2 | 1 | 0.8 | 0.4 |

| MDS202 | 24 | 40 | 12 | 6 | 4 | 2 | 1.6 | 0.8 |

| MDS301 | 30 | 60 | 15 | 7.5 | 6 | 3 | 2.4 | 1.2 |

| MDS302 | 60 | 120 | 30 | 15 | 12 | 6 | 4.8 | 2.4 |

| MDS303 | 90 | 180 | 45 | 22.5 | 18 | 9 | 7.2 | 3.6 |

| MDS351 | 60 | 120 | 30 | 15 | 12 | 6 | 4.8 | 2.4 |

| MDS352 | 120 | 240 | 60 | 30 | 24 | 12 | 9.6 | 4.8 |

| MDS353 | 180 | 360 | 90 | 45 | 36 | 18 | 14.4 | 7.2 |

| MDS354 | 240 | 480 | 120 | 60 | 48 | 24 | 19.2 | 9.6 |

| MDS401 | 100 | 170 | 50 | 25 | 17 | 8.5 | 6.8 | 3.4 |

| MDS402 | 200 | 340 | 100 | 50 | 34 | 17 | 13.6 | 6.8 |

| MDS403 | 300 | 510 | 150 | 75 | 51 | 25.5 | 20.4 | 10.2 |

| MDS404 | 400 | 680 | 200 | 100 | 68 | 34 | 27.2 | 13.6 |

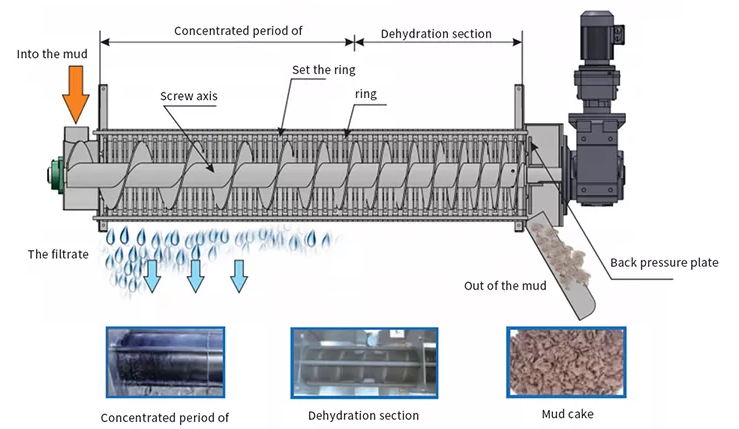

Working Process

1. Thickening: When the screw drive shaft rotates, the multiple solid and active laminations arranged on the periphery of the drive shaft move relative to each other. Under the action of gravity, water is filtered out of the relatively moving lamination gap to achieve rapid concentration.

2. Dewatering: The concentrated sludge moves forward with the rotation of the screw shaft; along the direction of the mud cake outlet, the pitch of the screw shaft gradually decreases, and the gap between the rings gradually decreases, and the volume of the spiral cavity Constantly shrinking; under the action of the back pressure plate at the outlet, the internal pressure gradually increases. Under the continuous continuous operation of the screw drive shaft, the water in the sludge is squeezed and discharged, and the solid content of the filter cake continues to increase, finally achieving sludge Continuous dehydration.

3. Self-cleaning: The rotation of the screw shaft pushes the moving ring to continuously rotate. The equipment relies on the movement between the fixed ring and the moving ring to achieve a continuous self-cleaning process, thereby cleverly avoiding the common blocking problem of traditional dehydrators.

FAQ

We always put the quality as the first consideration! If you need further information , feel free to contact Us! We are more than happy to help you with any inquiry. Call us or send us an email, and we’ll be ready to assist you.

1.Q:Are you a factory or trading company?

A: We are a factory, we have rich experience for manufacturing water processing equipment for more than 10 years.

2.Q:Where is your factory located? How can i visit there?

A: Our factory is located in Jinggui West Road No.16, Hudai Industrial Park, Wuxi, China, welcome to visit our factory.

3.Q: Do you have minimum order quantity request?

A: No minimum order, but it can get a discount if you order a large quantity.

4.Q: Do you have certificates?

A: Yes, we have ISO,SGS certificate.

5.Q: Can you meet my special requirements for my products?

A: Yes, we have a professional design team. We can provide drawings according to your requirements.

6. Q: How to buy your idea products?

A: You can provide us your water sources, water quality, flow rate and ground area (contact us for more details).

7. Q: How to pay?

A: TT and L/C are acceptable and TT will be more appreciated. 30% deposit before producing, 70% balance before loading by TT.

8. Q: What is the delivery time?

A: It depends on order quantities. Generally speaking, the delivery time will be within 4 to 6 weeks.

9. Q: How to pack the products?

A: We use standard package. If you have special package requirements, we will pack as required, but the fees will be paid by customers.

10. Q: How to keep your equipment from corrosion?

A: We use the world-famous paint, like SigmaCoatings, PainBow,etc. What's more, we paint strictly according to the standard process.

11. Q: How do you manufacture your equipment?

A: Our machining technology includes laser/plasma cutting, automatic welding, CNC cutting and bending.

12. Q: How to install after the equipment arriving destination?

A: We will provide detailed illustrations to you. If it is necessary, we will send technicians to help you. However, the visa fee, air tickets, accommodation, wages will be paid by buyers.