DongGuan BG Precision Mold Parts CO., Ltd |

|

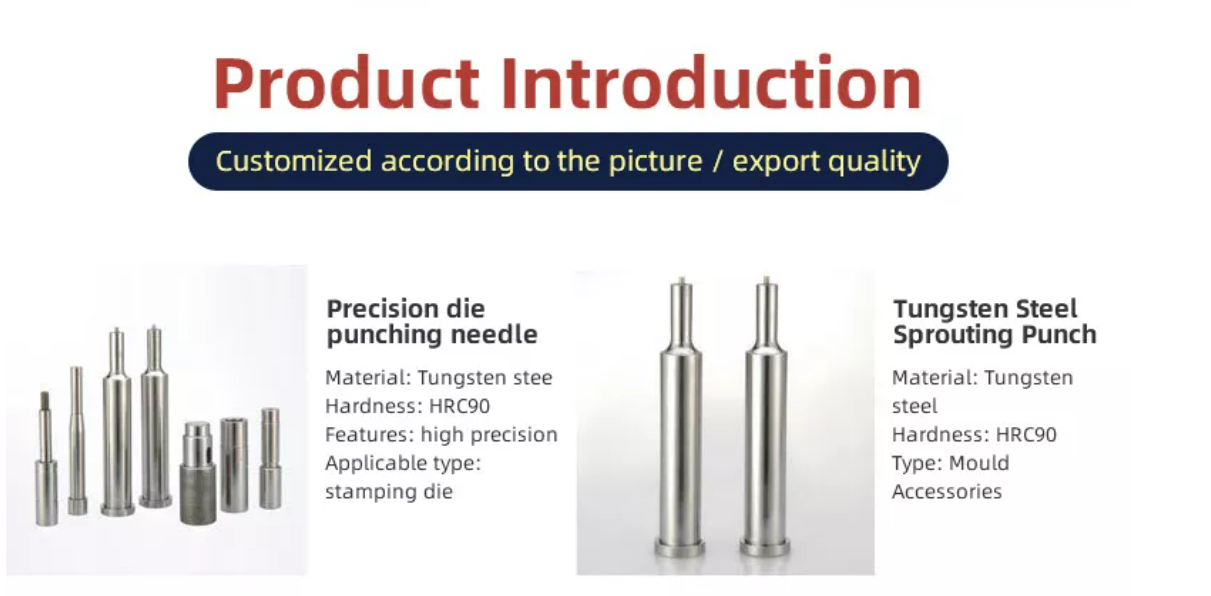

SKD61 High Precision mold parts injection mold parts sprue bush EN sprue bushing for plastic mould parts

BG is professional manufactory of precision mould parts,machine blades, special cutting tools, plastic moulds, auto mould parts, medical mould parts, packaging mould parts, cosmetic mould parts, connector mould parts, Packing Industry, Tobacco Industry, Food Industry, Plastic recycling Industry and other industries,etc...

BG has 13 years' experience,

With strong research and production capability, the products can meet the standards of superb quality and diversification,our experienced engineers are always here for backup.

Your Success, our Business!

Thanks for paying attention to us and we sincerely hope to have good business with you!

| Manufacturer | Dong Guan BG Precision Mold Parts Co., Ltd. |

| Product Name | punch pin |

| Materials | 45#,S50C,CR12/CR12MOV,SKD11,DC53,SKH-9,SKH-51,SKH-55,ASP23,ASP30,ASP60,CD650,2210,YG15,YG8,V30,KD20 etc |

| Standard | Standard Hardware/ Plastic Parts as per MISUMI, DME, HASCO, FIBRO,

CUMSA, STRACK, DAYTON NON-Standard parts can be designed or made customized |

| Hardness | HRC58-60,HRC64-66,HRC88-90 |

| Tolerance | ±0.001mm |

| Surface treatment method | Black-plated titanium, yellow-plated titanium, chrome-plated, nickel-plated |

| Heat treatment method | High frequency quenching, vacuum heat treatment, quenching and tempering treatment |

| Production address | Dong Guan,GuangDong,China |

| Lead Time | Sampling: 3-5 workdays Normal making: 5-10 workdays Complex design/making: 10-18 workdays Any urgent case,pls let us know,will try best to help. |

| Order Process | Customer inquiries → Provide Spec./CAD/3D drawing → Engineer check

and quote → Offer PI → Customer Send PO → 50% advanced payment(100% for First time cooperation) → Factory production process → QC passed → Packing and deliver at the first time → Fly to customers' hands soon! |

| After-sales service | If you have any questions about the samples or products, please contact us, our team will solve the problem for you |

● Support customized service, OEM service,small batch purchase,Fast reaction.

● High quality and guarantee,Using quality environmental protection material.

● Our product specifications are complete and diverse.

● Our products are well-known for its fine quality.

● Customer always first,We pay special attention to product quality and delivery.Fast response within one working day.

● Meet customer needs,Competitive price with high quality.

● Professional production team can provide you with logo, color, pattern custom.

● Can meet customers' invididual needs

1

Business Range

Manufacturing & inspection capacity in steel, stainless and copper materials for precision mould parts,Cavity pins, core pins,Punches,Ejector sleeve,CNC machining parts and all other precision non standard mould components, etc...

Services:CNC machining,CNC Milling,Sodick EDM,Sodick Wire-cut,OD grinding,ID grinding,Surface grinding,Thread grinding,Polishing etc..

Industries Served: Medical/Packaging/Aerospace/Electronic

If you have some questions about plastic moulds, or want to know more about auto mould parts, medical mould parts, packaging mould parts, cosmetic mould parts, connector mould parts etc. Welcome to contact us!

BG has strict quality control system from the raw material incoming to finished products outgoing. Our mould parts are guaranteed high precision,high polished and long service life.

Below are our main quality inspection items in the whole production process:

Material incoming: 100% inspection

Rough Finished:100% inspetion

Heat treatment: random inspection

Face grinding: 100% inspection

Center-less cylindrical grinding: 100% inspection

OD/ID grinding: 100% inspection

EDM:100% inspection

Wire-Cutting:100% inspection

Packing: the final 100% inspection before the formal shipment

![]()

Q1.When can I get the price?

A :We usually quote within 24 hours after we get your inquiry. If it is very urgent, please call us or tell us in your email so that we will regard your inquiry as priority.

Q2.How long is the lead time for mold?

A :It depends on the mold’s size and complexity. Normally, the lead time is 25-35 days. If the molds are very simple and not in big size, we can work out with 15 days.

Q3.I have no 3D drawing, how should I start the new project?

A :You can provide us a sample, we will help finish the 3D drawing design.

Q4.Before shipment, how to make sure the products quality?

A : We are specialized in high quality products. We have QC to inspect the products before each shipment. You can come to visit our factory or ask a third party for inspection. Or we can send you videos to show the production process.

Q5. How could I pay them?

A : Paypal, Western Union, T/T, L/C are acceptable, so just let us know which is convenient for you.

Q6.Can I get discounts?

A : Yes, for big order, old customer and frequent customers, we give reasonable discounts.

Q7.Which Shipment way is available?

A : By sea to your nearest port.

By air to your nearest airport.

By express (DHL, UPS, FEDEX, TNT, EMS) to your door.