Friendship Machinery Co., Ltd |

|

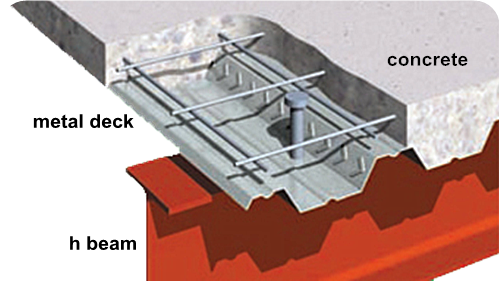

CE Approvals Double Layer Roll Forming Machine for Metal Deck And Steel Tile

1. Composition of machine

● Manual uncoiler: 1 unit

● Roll forming main machine: 1 unit

● Control panel: 1 unit

● Hydraulic station: 1 unit

● Manual out table: 2 units

2. Details of each composition

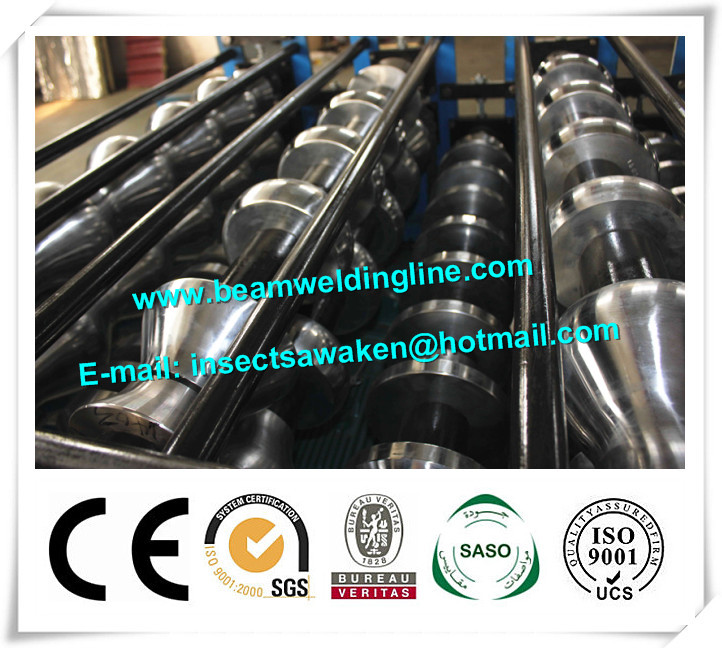

● Roll forming main machine

a. Coil width: 1220mm

b. Working speed: 10-12m/min (not contain cutting)

c. Roll station: upper is 20 stations and down is 22 stations

d. Material of roller: 45# forge steel, polished and coated with

chrome

e. Material of main shaft: 45# steel, diameter roller: Ф70mm

e. Main power: 7.5kw

f. Forming thickness: 0.3-0.8mm PPGL, G550MPA

g. Transmission: by single 1.5 inch chains

h. Size of machine: approve 8600*1500*1200mm and need one 40GP

container

i. Weight: about 8000Kgs

j. Color of machine: blue

k. Press and cutting:

- machine adopt hydraulic cutting

- hydraulic cutting after forming: cut the sheet

after roll forming to required length

- cutting motion: the main machine automatically

stops and the cutting will take place, after the cutting, the main

machine will automatically start

- material of blade: CR12with heat

treatment

- length measuring: automatic length measuring

- tolerance of length: 3m+/- 1.5mm

● Manual uncoiler

|  |

| ● Control panel Panasonic

|

● Hydraulic station

a. Hydraulic station power: 5.5kw

b. Hydraulic pressure: 10-12Mpa

● Manual out table

|  |

4. Technological process

● Uncoiling - Feeding - Roll forming - Cut to length - Product

packing manual