Allwin Machine & Equipment Co.,Ltd |

|

Verified Suppliers

|

|

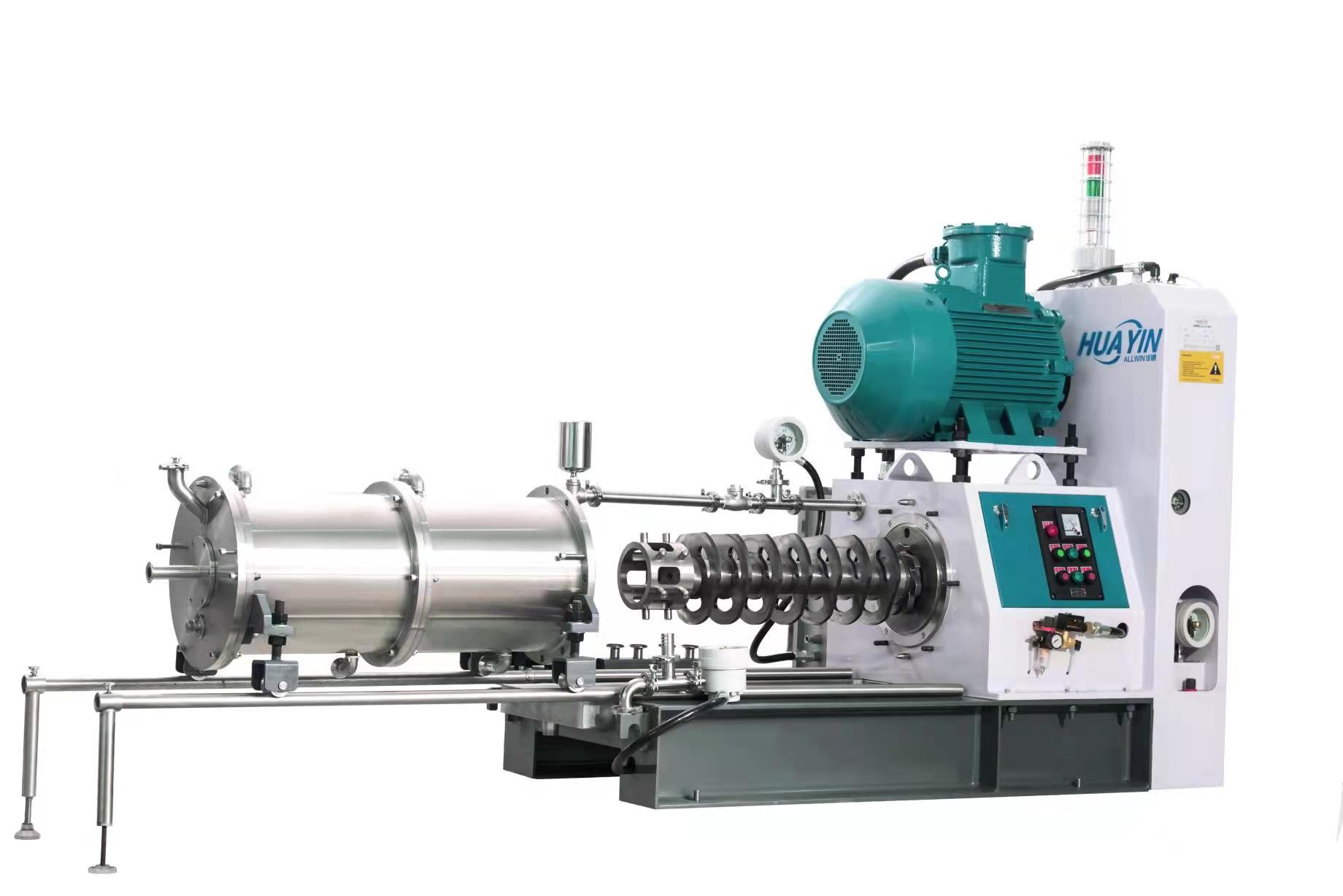

HZ PLUS50 Water Based Wet Grinding Horizontal Sand Mill In 3C,Car

Paint And Coating

Composite type bead mill machines are popular

in submicron grinding, especially suitable for car

paint, 3c coating,which requires that the finer the better.The

inner dispersing structers have different materials for

option, such as silicon carbide ceramics, Cr12Mov wearable

steel, 304 stainless steel, PU, etc.the operation manner can be

botton column or touching screen with PLC.

1. Technical data of sand mill

| No | Main Parameters | HZPLUS50 sand mill | Notes |

| 1 | Motor power (kW) | 37KW | Ex-proof/non ex-proof available |

| 2 | Effective volume of grinding chamber (L) | 50L | volume can be suggested according to different grinding materials and usages |

| 3 | Water pressure (MPa) | 0.3 | |

| 4 | Cooling water consumption (L/min) | 2.0-3.0 | Advision: Users offer the Cooling water less 10°C |

| 5 | Dimensions:L*W*H (mm) | 2050*1200*1850 | |

| 6 | Weight (kg) | About 1600 |

Main instructions:

| No | Main parts | HZ PLUS50 | Notes |

| 1 | Material of External vessel | SUS 304 stainless steel | |

| 2 | Material of Inner grinding vessel | SIC Ceramic,wearable steel,stainless steel,PU | different mateials for choice |

| 3 | Material of Dispersing shaft | 40Cr with hard chromium plating | |

| 4 | Material of dispersing system | Zirconia Ceramic,wearable steel.stainless steel,pu | Choose what you need |

| 5 | Feeding and discharging end covers on the cylinder | SUS 304 stainless steel | |

| 6 | dynamic discharge screen ring | Wire Wound screen ring with 304.Gaps: 0.5 mm. | dynamic scraper: alloy steel |

| 7 | Mechanical seal | Double end mechanical seal | |

| 8 | Feeding pump | 1" ARO diaphragm pump | IngersoII Rand |

The pictures of processing and inspection

The main processing equipment:

Packing and delivery: Wooden boxes and FUL or LCL container

The After sales service:

1. Video instructions for installation and commissioning, if need, we will arrange engineer to your factory.

2. 12-24H feedback any customers questions, firstly offer the video help you solving, if need, arrange maintenance engineer for you.

If need more detailed information and Price, please don't hesitate contact us, Also Warmly welcome to visit us.