Guangdong Saimai Industrial Equipment Co., Ltd. |

|

Verified Suppliers

|

|

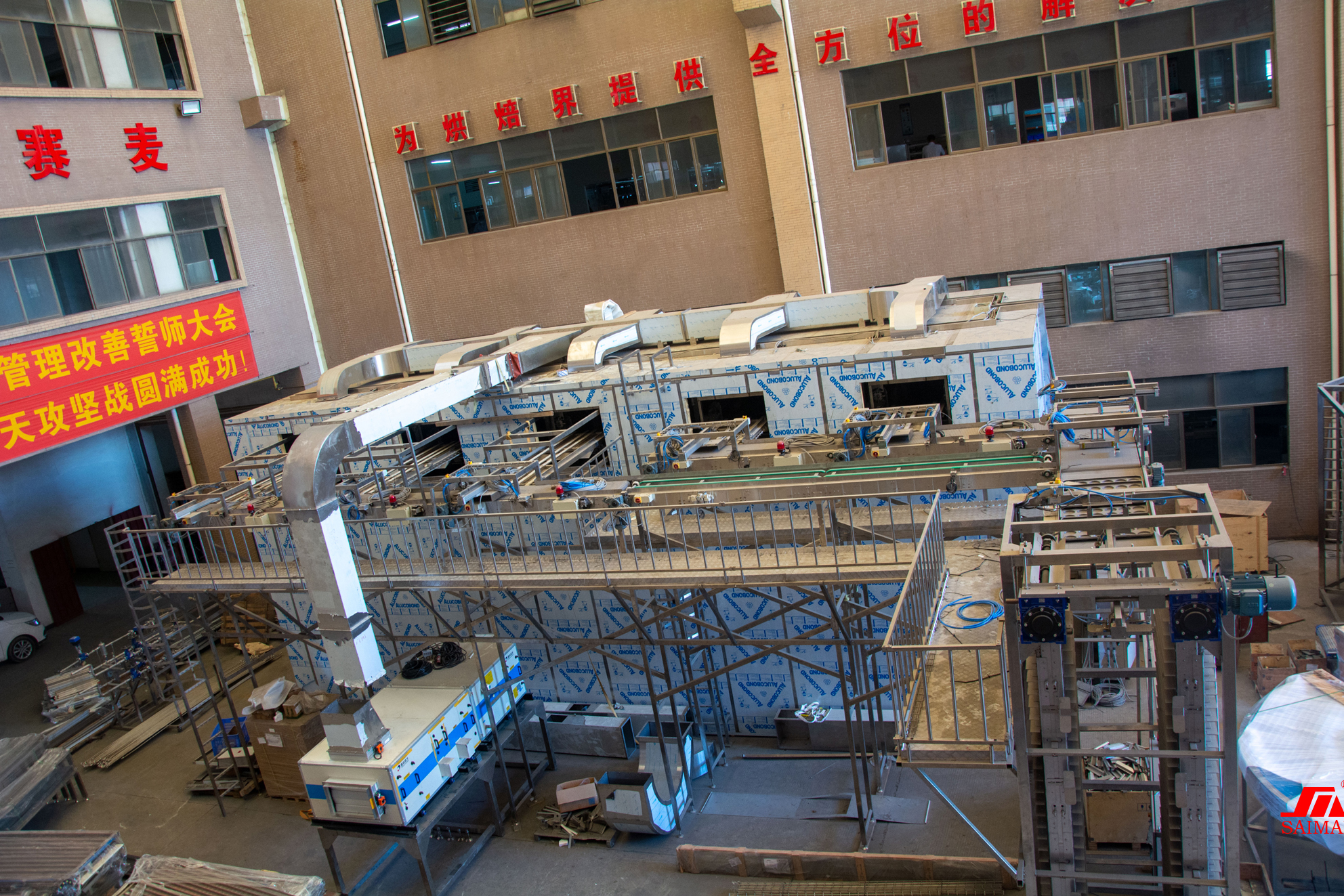

Bread Production Equipment Automated Danish Bread Production Line

The complete lines for producing the Danish bread are supplied by SAIMAI.

We can supply the machines that savings in the production costs and with high reliability, and thus then also to low demand for servicing.

For this type of production, the oven is generally equipped with bottom air circulation in the baking chamber, which aids in increasing the heat transfer using convection, creating a unified coloring of the product on all sides and in creating the lower crust of the bread.With regard to the client´s need, type of the production and the selected equipment we are capable to supply these lines as semi-automated and but also as fully automated for typical tin bread baked in pans without covers, which enable continuous automated operation.

Automatic or semi-automatic Proofing Room

Pans, trays can all be handled by the proofing room. Different tray types can be used as long as their outer dimensions are equal. The proofing room has several racks that consist of one or more levels, making the proofing time and capacity flexible without increasing the floor space.

The pans are fed into the proofer by conveyor and do not touch each other. Once a row is filled, it is lifted with an L-shape carrier. This process is repeated until the first dough has reached the top level. Then, the pans are moved out of the proofing room.

The proofing room is accommodated with a temperature and humidity control system and insulated housing.

Tunnel Oven

1: The oven is constructed gas-tight baking tunnel, divided into 2m/ section. Each section is connected on a frame, with a gas-tight connection between the sections.

2: the baking tunnel is insulated with 20CM-25CM layer of high-quality insulation material, in order to reduce heat loss to a minimum.

3. Inspection door on the control side

4. Stainless steel side and top outside panel.

5. The temperature is measured in each zone, both temperature underneath and above the product to be baked. PT-100 sensors are fitted in the baking tunnel for this purpose. The measured values for each zone can be read both on the central control panel (touch panel) and moisture instrument.

6. In the event of a driving motor failure, the belt can be driven by the hand device. This could send the product out of the oven.

7. OMRON PLC system is built into the control cabinet for the control of the oven.

Suction Depanner/ Needle Depanner

By means of a pick-and-place principle, a depanning head is positioned above pans; the (exchangeable) depanning head picks up the product and then transfers it to the cooling conveyor and releases it.

Spiral Cooling Tower

1. It can be customized to meet customer requirements and designed to be the most suitable size and structure for your product.

2. Reliably and practicability: It is in accord with ergonomics and durability.

3. Using SEW drive and SIEMENS DEIVE to ensure the stability of the equipment.

4. Strict food safety standard: Smooth and clean surface, opening design and stainless structure make it easy to be cleaned.

5. Its advantages as below: beautiful shape and good quality; transmit steadily and smoothly with low voice; easy operation and low maintenance cost.

6.Optional for the cleaning system, the cleaning system has circulating hot water, steam cleaning, residue removing, and strong wind function.

Conveyors

1. PLC systems can monitor faults and showing alarm information in English according to the customer’s requirement. It has an open communication interface for the internet and is free to connect with other controlled systems and computer systems.

2. Incorporated the design of Europe and Japan into our equipment. Maximum reduce the cost of labor and realize real automation.

3. According to the workshop area and the requirement of manufacturing to perfectly design the size and structure.

Our worksop:

Packaging and delivery: