Waste Plastics Recycling PP PE Film Compacting Granulator Machine Recycling Granulator pe pp film flakes pelletizing line plastic granules making machine pp pe granulating machine pelletizing line for PE film Double Stage Recycled PE PP HDPE LDPE Plastic Pelletizing Making Machine Granulator Plastic Pelletizing Machine Pellet Recycling Machines Plastic Granulator For Pp Pe Film pellet recycling machines plastic granulator for pp pe film

| Model | Screw Diameter | Screw L/D | Second Screw L/D | Main Motor Power | Capacity |

| SJ85 | 85mm | 28-33:1 | 10-12:1 | 55KW | 150-200kg/hr |

| SJ100 | 100mm | 28-33:1 | 10-12:1 | 75KW | 200-300kg/hr |

| SJ130 | 130mm | 28-33:1 | 10-12:1 | 90KW | 300-400kg/hr |

| SJ150 | 150mm | 28-33:1 | 10-12:1 | 110KW | 400-500kg/hr |

| SJ160 | 160mm | 28-33:1 | 10-12:1 | 132KW | 500-600kg/hr |

| SJ180 | 180mm | 28-33:1 | 10-12:1 | 160KW | 600-800kg/hr |

| SJ200 | 200mm | 28-33:1 | 10-12:1 | 200KW | 800-1000kg/hr |

| | | First stage extruder (kw) | second stage extruder (kw) | |

| | | | | |

| | | | | |

| | | | | |

| | | | | |

wet film or woven bags pelletizing line:

1. Material: different type of PE film ,which can process PE film /PP woven bag withmoisture below 25%

2. Capacity: 500kg/hour

3. Total install power: around 330kw, when machine run stable, the extruder and mold just need keeping temperature, no need heating again, so the actual power consumption 70-80% less.

4. Voltage:380V/3phase/50HZ

5. Workshop Dimension: 15m (length)×5m(width)×3m(height)

6. Water consumption: around 5m3/hour (it can be recycled by water chiller)

7. Air consumption: no need

8. Temperature environment: ≤40℃ 9. Manpower: 1-2 people

The flow chart as following:

Belt Conveyor→ Force feeder→ SJ200 Single screw extruding machine→ High speed Net exchanging system with its die-heads→ SJ180 Single screw extruding machine→ High speed Net exchanging system with its die-heads→water cooling bath→ Air dryer→ cutting machine→ vibrator sieve →Air Blower → Silo

| Model | Screw Diameter | Screw L/D | Second Screw L/D | Main Motor Power | Capacity |

| SJ85 | 85mm | 28-33:1 | 10-12:1 | 55KW | 150-200kg/hr |

| SJ100 | 100mm | 28-33:1 | 10-12:1 | 75KW | 200-300kg/hr |

| SJ130 | 130mm | 28-33:1 | 10-12:1 | 90KW | 300-400kg/hr |

| SJ150 | 150mm | 28-33:1 | 10-12:1 | 110KW | 400-500kg/hr |

| SJ160 | 160mm | 28-33:1 | 10-12:1 | 132KW | 500-600kg/hr |

| SJ180 | 180mm | 28-33:1 | 10-12:1 | 160KW | 600-800kg/hr |

| SJ200 | 200mm | 28-33:1 | 10-12:1 | 200KW | 800-1000kg/hr |

| | | | | | |

Description

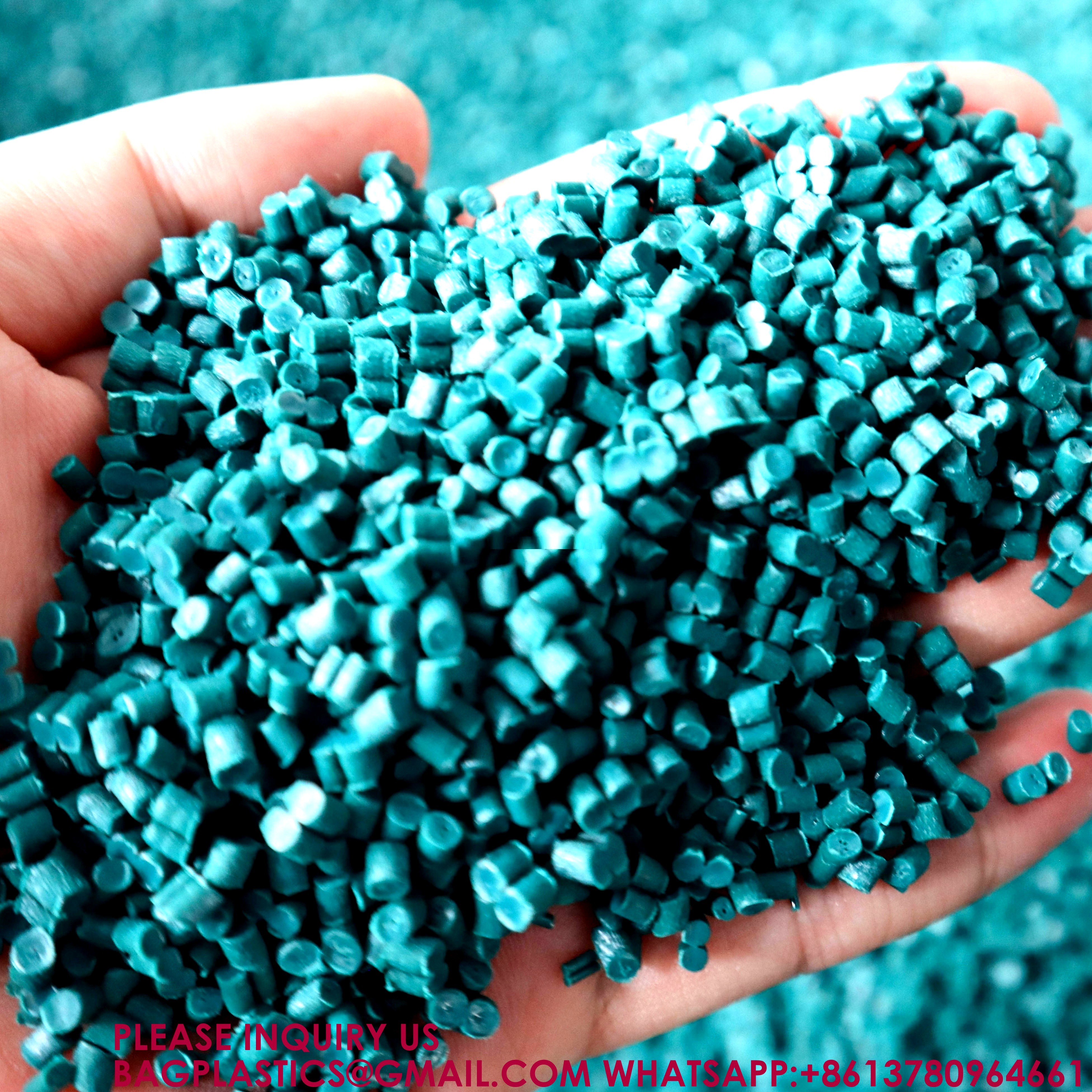

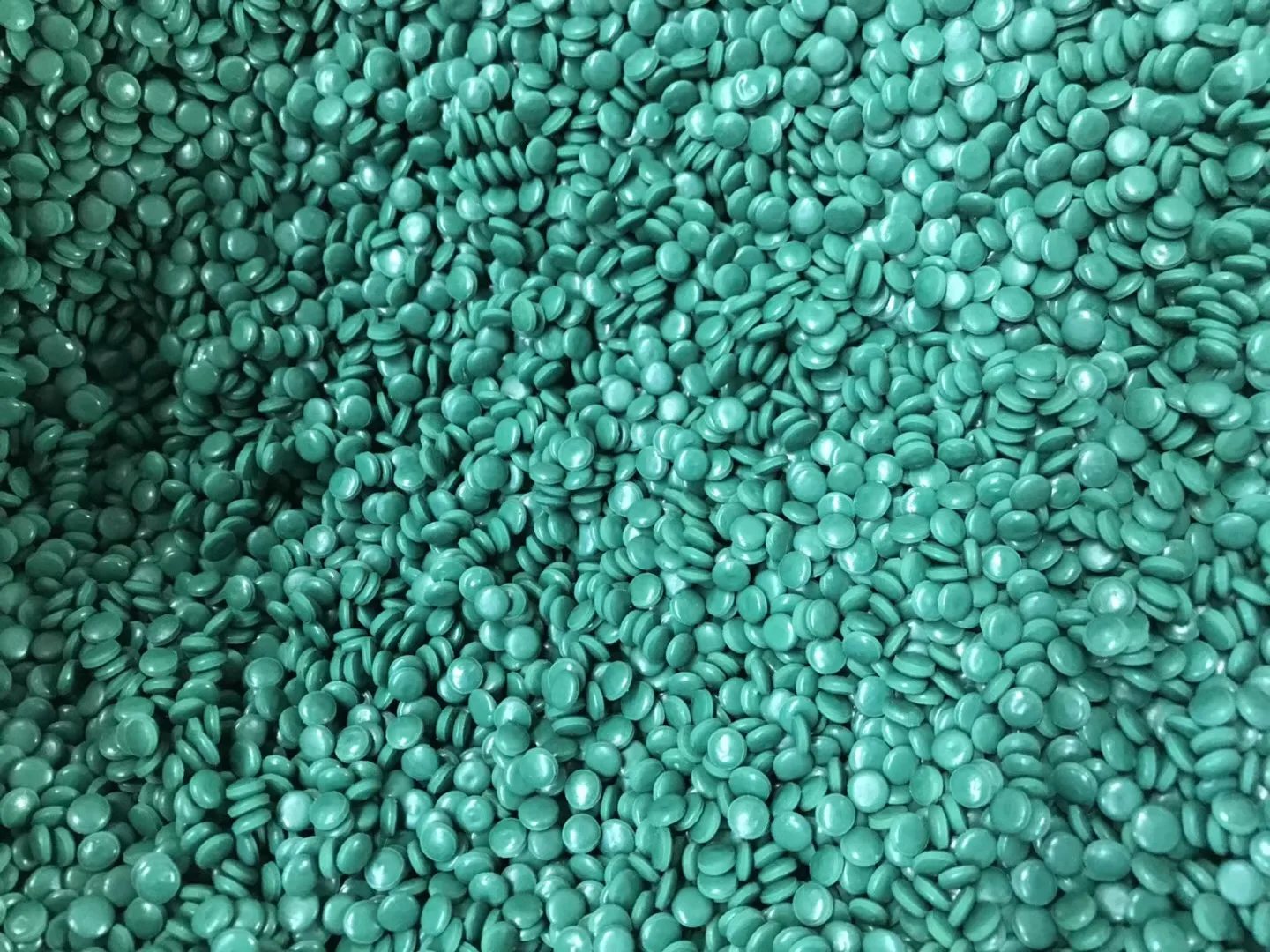

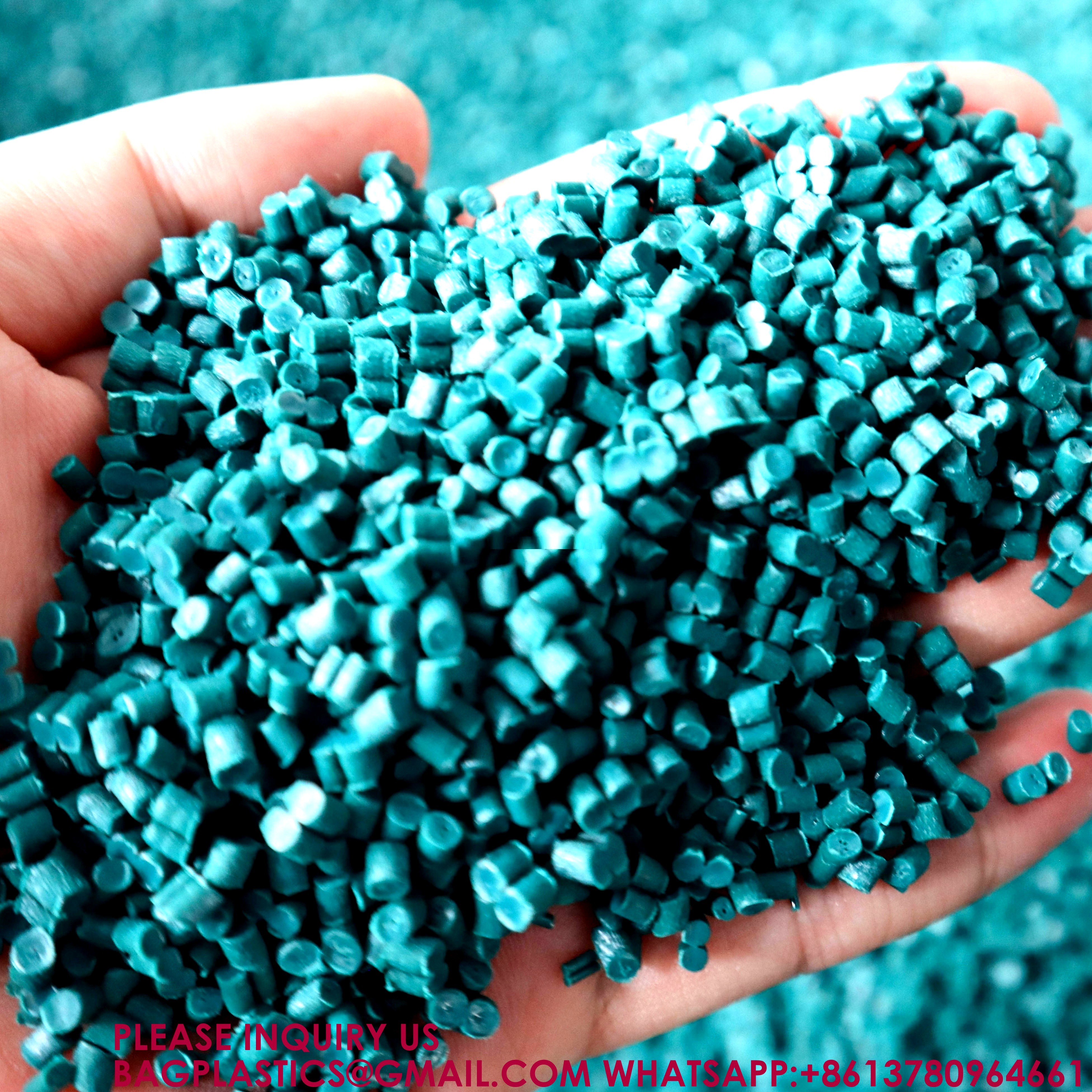

Plastic pelletizing granulator machine is used to recycle various kinds of plastic products and make plastic into granules to recover the plastic and suit for making products again.

We're very professional manufacturer of plastic recycling machinery, and We have been working in this industry for over than 15 years, We have developed many different kinds of plastic granulators for different material, such like PP PE PVC PET PC ABS EPE EPS, Printed and non-printed PE, PP film, multi-layered film, shrink film, stretch film, PE and EPE foam, Thermoformed PS, PP, Soft irrigation pipe, Pre-shredded regrind, Washed and dried film flakes from washing line,Hard Plastic Regrind, Washed Material, Granules, HDPE-milk-bottles etc. And adopt different feeding ways for rigid flakes and for soft fluffy scraps. Output capacity will be from 100KG/H up to 1000kg/H.

Plastic pelletizing granulator machine is used to recycle various kinds of plastic products and make plastic into granules to recover the plastic and suit for making products again. We’re very professional manufacturer of plastic recycling machinery, and We have been working in this industry for over than 15 years, We have developed many different kinds of plastic granulators for different material, such like PP PE PVC PET PC ABS EPE EPS, Printed and non-printed PE, PP film, multi-layered film, shrink film, stretch film, PE and EPE foam, Thermoformed PS, PP, Soft irrigation pipe, Pre-shredded regrind, Washed and dried film flakes from washing line,Hard Plastic Regrind, Washed Material, Granules, HDPE-milk-bottles etc. And adopt different feeding ways for rigid flakes and for soft fluffy scraps. Output capacity will be from 100KG/H up to 1000kg/H.

| Plastic Processed | HDPE, HDPE/PP, PE/PP, Lldpe, PP, MLLDPE, LDPE |

| Condition | New |

| Output (kg/h) | 300kg/h - 800kg/h |

| Video outgoing-inspection | Provided |

| Machinery Test Report | Provided |

| Marketing Type | New Product 2020 |

| Warranty of core components | 1 Year |

| Core Components | PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump |

| Place of Origin | China |

| Type | Granulating Production Line |

| Screw Design | Single |

| | 120 |

| | 33:1 |

| | 100rpm - 120rpm |

| Voltage | 380V |

| Dimension(L*W*H) | 12000/3600/2500 MM |

| Power (kW) | 90 |

| Weight | 10 |

| Warranty | 1 Year |

| Showroom Location | Egypt, Pakistan, Thailand, Romania |

| Applicable Industries | Manufacturing Plant |

| Material | PP/PE |

| Name | double stage ldpe plastic granulation recycling machine line price |

| After-sales Service Provided | Engineers available to service machinery overseas |

| Application | Granules Production |

| Raw material | PP PE Material |

| Color | Custom- Made |

| Material Processed | Compacting ---pelletizer---cutting ---drying |

| Machine | Plastic Recycling Pelletizing Line |

| Product name | Plastic Granulator Pelletizing Granules Making Machine |

| Machine Type | Double Stage Pelletizing |

double stage compactor granulator line

| Model | | | | | | |

| Screw Dia.(mm) | | | | | | |

| L/D | | | | | | |

| 1st stage | | | | | | |

| 2nd stage | | | | | | |

| Motor of compactor(kw) | | | | | | |

| Motor of 1st stage(kw) | | | | | | |

| Motor of 2nd stage(kw) | | | | | | |

| Capacity(kg/h) | | | | | | |

For plastic machines, our main products include: big-mouth PVC pipe extrusion production lines, PE big-mouth for gas, water supply extrusion production lines, PET bottle recycling line PE/PP film recycling line PVC/WPC foam board extrusion line PVC/WPC profile extrusion line PP hollow sheet extrusion line HDPE/LDPE pipe extrusion line PPR PIPE extrusion line plastic extruders, high speed mixers and various plastic auxiliary machines. Please feel free to contact us for further details. We are looking forward to forming a profitable business relationship with your company in the near future.

compactor

crush pp/pe film into small scraps and feed into the screw barrel There is a temperature testing point inside the machine the compactor system with one glass window to see inside and with light too the compactor system with one well closed big door which is used to clear the remaining material of inside compactor There is a light for checking the material inside of compactor There is a water sprinkler inside of compactor When the temperature of barrel is high temperature, the water spray system will be automatic spray the water.

pp pe film pelletizing line/ Plastic film granulator

Usage: This water-cooling single screw plastic pellet making machine is double stage plastic regenerative pelletizer, which is suitable for many kinds plastic waste materials recycling and making pellet, such as PP, HDPE, LDPE, LLDPE Film and clean woven/nonwoven bag materials, etc. The film can be pressed in compressor and then be pelleted.And also has very developed design, makes sure this machine has a long working life and economical efficiency in using.

Characteristic: 1. Screw and barrel, inlet mouth treated with special alloy: very strong and long life. 2. Easy operation: it has automatic constant temperature control and stable performance. After adjusting well, 1 or 2 workers are enough to run this machine, to feed the materials and change pellet receiver. 3. Low cost in using after redesign: now this kind machine is more economic in electric power source and also water. In the long working life of this machine, it can save many sources in energy! 4. High output, long operating life and lower noise: it’s the ideal waste plastics regenerative pelletizer machine for nowadays.

Why choose us? 1.Low cost All the machine ,we make by ourselves to reduce the cost for our customers.

2.Genuine product with excellent quality We choose our material very strict. All the material come to our factory must pass the quality test Substandard goods are returned to the supplier.

3. Engerneers available to serve oversea PLEASE INQUIRY US

BAGPLASTICS@GMAIL.COM WHATSAPP:+8613780964661

4.Quick delivery The company provide just in time delivery with its streamlined supply chain.

5.Cost saving We take strong attention to every detail in the manufacturing process. The quality control in our factory is very strict. All defective semi-manufactures must be treated again or rejected. All the machine must be checked before delivering to our customer. What we want to do is to give our customer a good quality product with stable and long time working life.

PLEASE INQUIRY US

BAGPLASTICS@GMAIL.COM WHATSAPP:+8613780964661