shenzhen xingte technology co.,ltd |

|

Verified Suppliers

|

|

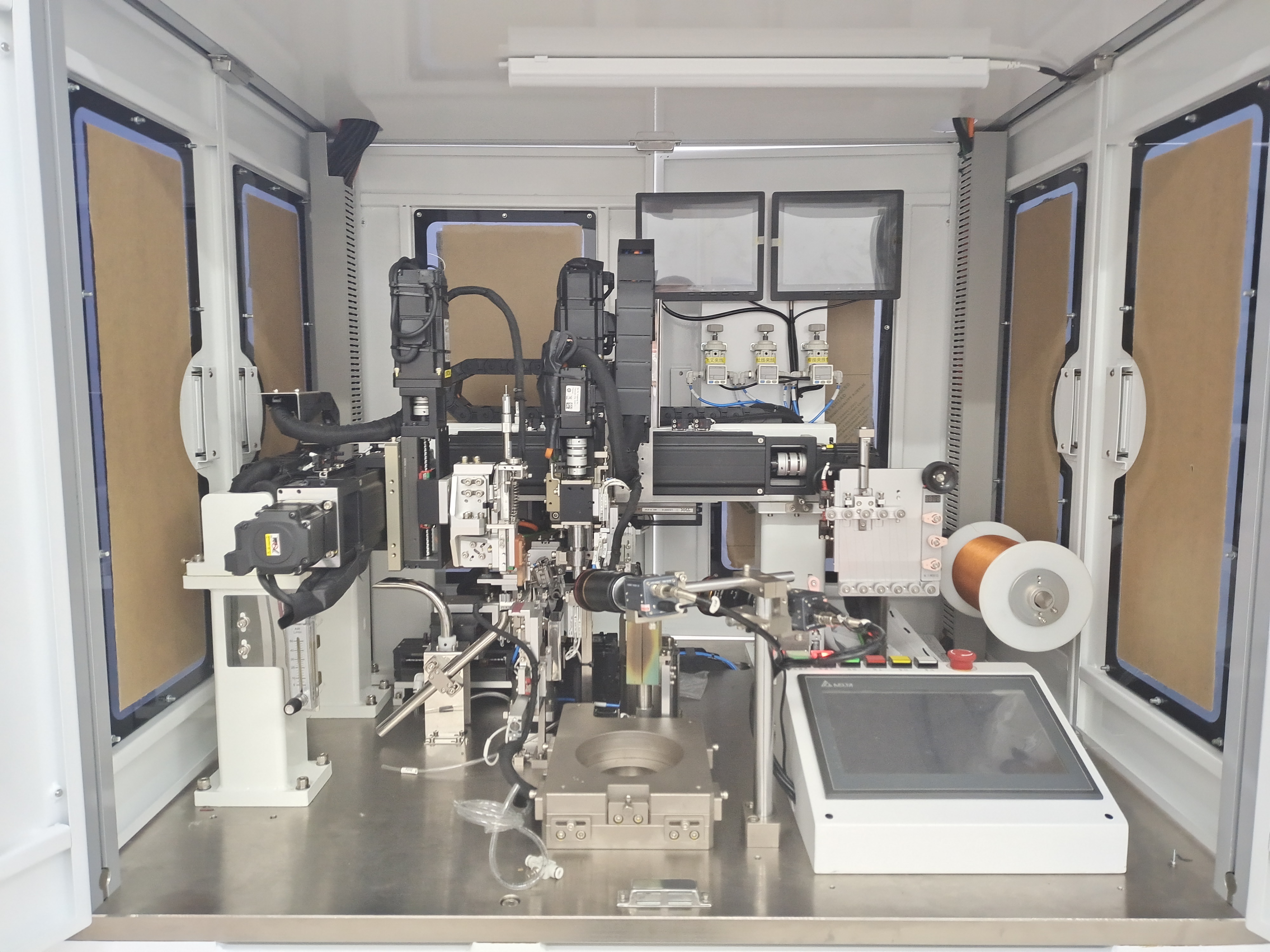

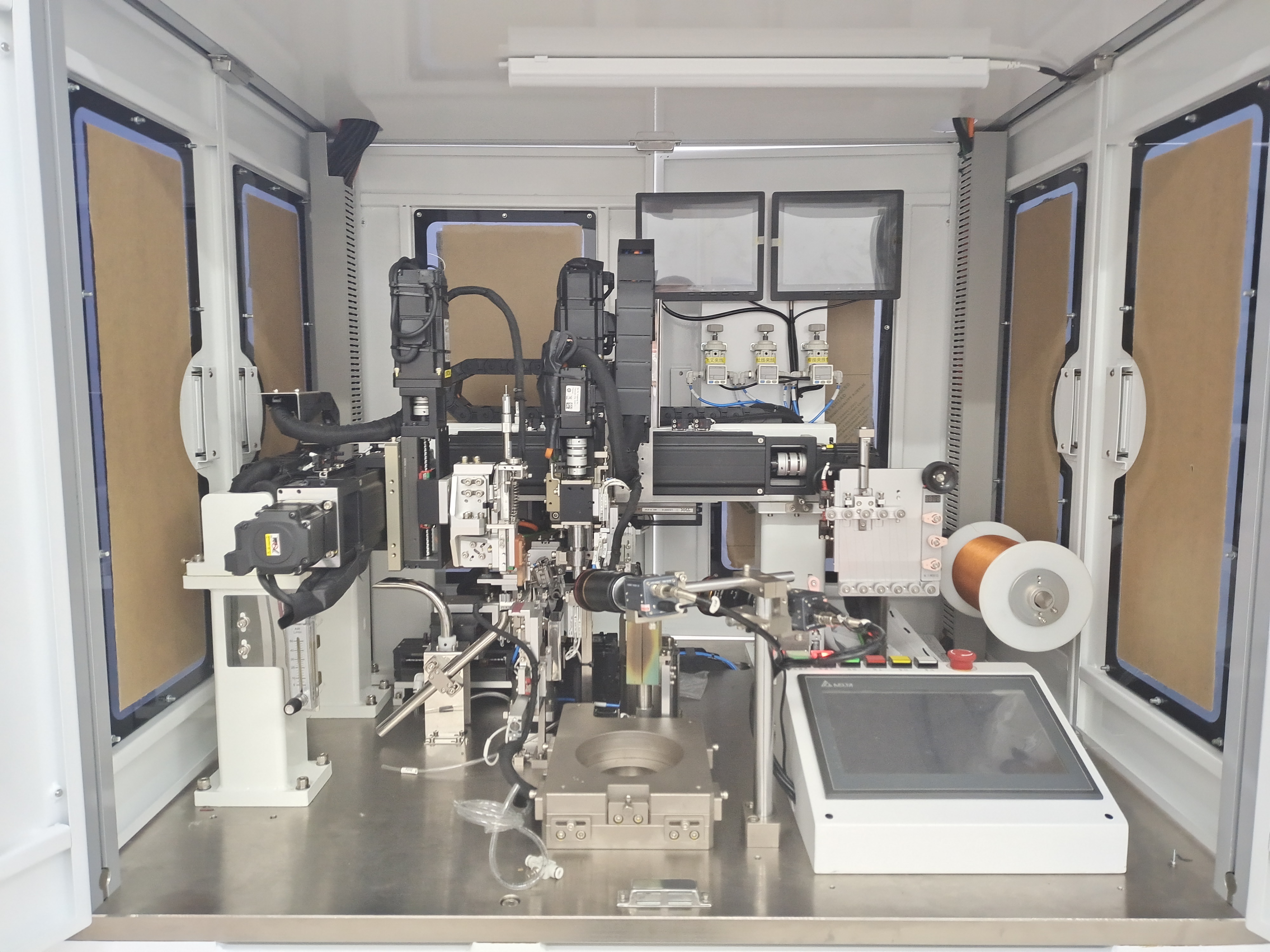

High efficient and Stable Tcore Integrated Inductor Winding Machine XT-M01

XINGTE has developed and customized Tcore unibody inductor winding

machines to meet market demands independently. The servo motor uses

bus control, key parts are processed independently using precision

equipment, and standard parts are all top international brands. Key

parts have a life management system in place. The output can reach

3000pcs/h, with a yield rate of over 99%, and only 0.5 operators

are required. This product can be applied to various fields like

computers, smartphones, smart wearables, automobiles, etc. The main

process flow of the integrated inductance winding equipment

involves magnetic core feeding, winding, line arrangement, and

outputting products based on customer requirements. Magnetic core

feeding is done via a Tcore vibration plate, with 6s/pcs at a time.

The winding process involves winding a flat wire on the magnetic

core using pair winding. Hot air is self-adhesive while winding.

After winding, the line is arranged by hanging the line gauge,

cutting off the excess tail line, and welding and fixing it on the

magnetic core. Finally, products are outputted according to

customer requirements.

Tcore Integrated Inductor Winding Machine

The process flow of the Tcore Integrated Inductor Winding Machine includes:

Magnetic core loading: Magnetic core Tcore vibration plate loading,

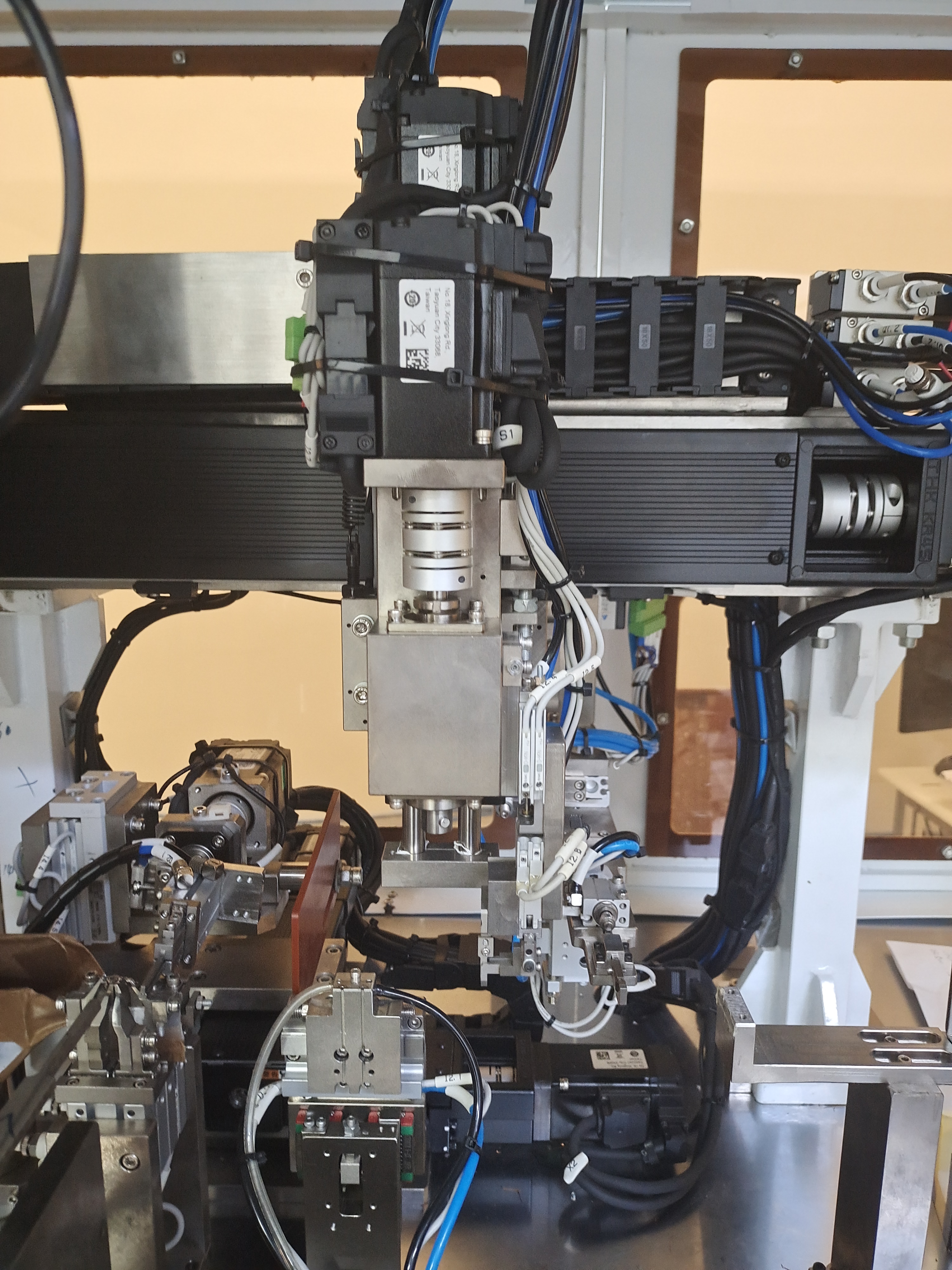

Winding: Flat wire is wound onto the magnetic core, using a bifilar winding technique, with hot air applied for self-adhesion as winding proceeds;

Wire Management: Arrange the wire neatly, trim any excess tail wire, and then solder it securely to the magnetic core.

Unloading: Discharge the product according to customer requirements.

The advantage of our Tcore Integrated Inductor Winding Machine

The machine's servo motor uses bus control, and its key components are made in-house with precision equipment.

All standard parts are sourced from international brands, and key components undergo life-cycle management.

One staff can handle several machines, which saves labor cost

It has a production capacity of up to 9000 pieces per hour.

The yield rate can reach above 99%.

In addition, multi-axis simultaneous winding is possible.

Product Features

·The equipment has fast production efficiency and fully automatic

loading and unloading;

·The equipment can work with multiple types of material numbers:

1608 series, 2012 series, 2016 series, 2520 series, 3225 series;

·Simply switch different specifications of fixtures for different

material numbers to work;

·You can view real-time production and equipment operation status

in the equipment, and monitor production information in real time.

This production line is used for manufacturing T-core type small-size molded inductors, which can be applied to computers, smartphones, smart wearables, automobiles, and other fields.

Product parameters

| Model number: | XT-M01 |

| Feeding method | vibrate plate |

| Capacity | 2.2-3S/Pc |

| operating height | approx 1m |

| Yield rate | > 98% |

| Utilization rate | >85% |

| Control Method | PLC bus control |

| Power: | 3.5KW |

| Power supply: | AC 220V,50/60Hz |

| Air pressure: | > 0.6Mpa |

| Machine dimension: | 1125*850*1900mm |

| G. W: | 400KGS |

Basic information about XINGTE

Experience

XINGTE was established in 2007, with more than 17 years R & D

experience in the coil winding area

Plant Size

XINGTE is headquartered in Shenzhen, with a factory area of more

than 30,000 square meters, which can ensure our Strong productivity

Service

XINGTE has more than 230 technical service and after-sales staff,

worldwide service points worry-free after-sales service

Patents & certificates

Patents & certificates:

XINGTE obtained 120+ Patents and related certificates

Production Capacity

XINGTE has more than 600 experienced employees, which can guarantee

our Production capacity and fast delivery

Technology

XINGTE has more than 130 experienced engineers, which can ensure

our strong R & D ability, also can guarantee our customization

capability

XINGTE PRODUCTION LINE

1, Motor stator, rotor, and other related coil winding

machine

2, Transformer-related product coil winding machine

3, voice coil-related product winding machine

4, inductor coil winding machine and

5, customized fully automatic line for the motor, speaker,

transformer production line

Our Machine

Our factory

Finished product

Delivery

Order process