zhangjiagang aquatrin Machinery co.,ltd |

|

Product Description

Automatic Beverage Bottle Water Liquid Filling Machine

This automatic rinsing, filling and capping machine, could be

applicable quantitative filling and capping of drinking water,

mineral water, pure water. It has functions as follows:

Disinfectant rinse, aseptic water rinsing; automatically i liquid

filling tank, inlet material; feed bottles by air conveyer (or

screw convey); automatically rinse, open valve and feed caps; not

rinse, open valve and feed caps without bottles.

Compact structure: reasonable design and convenient operation and

maintenance. Main machine is adopted frequency speed control, it

runs stable and credibility. Material of contacted with product we

use high food grade stainless steel. After exchanging changeover

parts, it is applicable for different kinds of PET bottle filling.

We adopt advanced touch screen operation and realize human-machine

communication. Function of control system as follows: product speed

control, automatic stop with faults and take count of output, etc.

| EQUIPMENT TYPE | Full automatic |

APPLICATION FOR BOTTLE | Round or square bottle Volume 200 - 2000ml Diameter: Φ50~120mm Bottle height:160~320mm Diameter of bottle mouth: Φ25~38mm |

| CAPACITY PER HOUR | 2000~24000BPH |

| GUARANTEE | Free warranty since12 months after installation & commissioning, or 15 month after delivery date |

| AFTER SERIVCE | Life- long maintenance |

| |

2.Filling part

| |

3.Capping part

|

Technical parameter

| Model | CGF8-8-3 | CGF18-18-6 | CGF24-24-8 | CGF32-32-12 | CGF40-40-12 | CGF50-50-15 |

| Capacity(500ml) | 2000 | 6000 | 10000 | 14000 | 17000 | 24000 |

| Bottle height(mm) | 150-340 | |||||

| Bottle diameter(mm) | φ50-φ110 | |||||

| Filling temperature | Room temperature | |||||

| Power(kw) | 2.5 | 3.1 | 3.8 | 5.6 | 7.6 | 9.5 |

| Overall size(mm) | 2000×1500×2200 | 2400×1830×2400 | 3100×2200×2400 | 3800×2500×2400 | 4000×2800×2400 | 5450x3200x2400 |

Auxlllary equipment

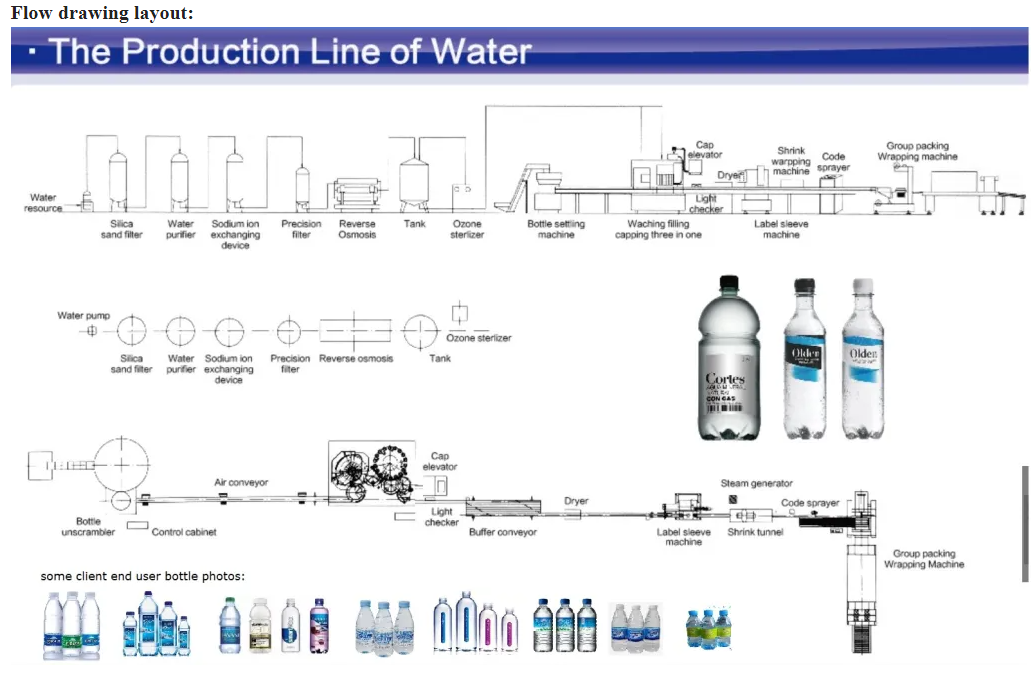

1.RO WATER TRATMENT SYSTEM

| |

2.BOTTLE BLOWING MACHINE

| |

3.LABELING MACHINE

| |

4.PE FILM SHRINK WRAPPING PACKAGE MACHINE

|