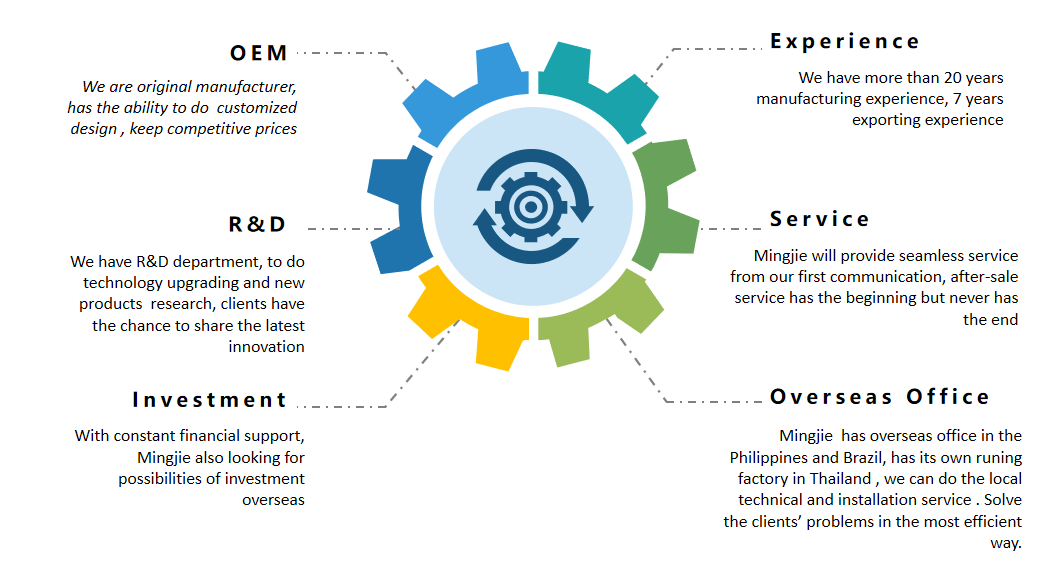

Henan Mingjie Environmental Equipment Co., Ltd. |

|

Verified Suppliers

|

|

Item | Content | ||||||

Models | No | Capacity | Reactor size | Operation | |||

MJ-2 | 1-2T Per Batch | 1400*4000mm | Batch | ||||

MJ-6 | 6T/D | 2200*6000mm | Batch | ||||

MJ-10 | 8-10T/D | 2600*6600mm | Batch | ||||

MJ-12 | 12T/D | 2800*7100mm | Batch | ||||

MJ-15 | 13-15T/D | 2800*8000mm | Batch | ||||

MJL-15 | 16-20T/D | 2800*7100mm | Semi-continuous | ||||

MLL-20P | 30T/D | 1600*26000mm | Fully continuous | ||||

MLL-30T | 35-40T/D | 1600*26000mm | Fully continuous | ||||