Qingdao Huichen Logistics Technology Co.,Ltd |

|

High Density Industrial Automatic Warehouse Racking System

Automated Storage Crane

Automatic Warehouse Storage System (AS/RS) use an interated

logistics management computer control system and use advanced

technologies such as laser positioning technology, barcode sanning,

and Rf system. The WMS can exchange information with EPR system,

with multiple functions and reliable performance. The automatic

warehouse system plays an increasingly important role in the

warehouse and distribution centers of various industries.

AS/RS consists of racking system, stacker crane, conveyor system,

electrical control system, network, and management system.

The most advantageous part of the automation system is fast and

accurate,100% FIFO and picking. The system height can reach more

than 30 meters, and the length is better more than 40 meters.

Height and length can be designed according to requirement.

Benefits of AS/RS System

1. Dramatic improvements in operator efficiency and storage

capacity .

2. Reduction of work-in-progress inventory .

3. Improvements in quality and Just-in-Time performance .

4. Provides make-to-order capability in addition to

make-to-inventory production .

5. Real-time inventory control and instantaneous reporting

functionality .

Structural feature

1). Double upright structure, steady and reliable, vector frequency

conversion drive and encoder position control, mechanical and

electronic safety devices to ensure safe using of the system; all

the way tracing technology by information transferring;

2). electric components are imported from abroad; touching screen

interface for easy operation; making manual, semiautomatic,

automatic and linkage control come true; used in many situations by

combining with other logistics equipment.

ASRS warehouse rack mainly consists of following parts:

| Racking | Structural feature: AS/RS System are usually equipped with pallet racking and drive-in racking, both of which are composite structure. Steel panels and wooden panels are available for loading with good capacity. Conveyors will do the loading and unloading job under the instruction from the central computer. AS/RS System is mainly used in the food, tobacco, electronic, mechanical and armament industry. |

| Stacker | Structural feature: Double upright structure, steady and reliable, vector frequency conversion drive and encoder position control, mechanical and electronic safety devices to ensure safe using of the system; All the way tracing technology by information transferring; Electric components are imported from abroad; Touching screen interface for easy operation; Making manual, semiautomatic, automatic and linkage control come true; Used in many situations by combining with other logistics equipment. |

| Conveying system | Structural feature: Conveying system is usually equipped in the front or back of warehouse for conveying goods here and there, bridging the procedures done by forklifts and stackers by using rolling conveyor or chain conveyor and combining with lifts, rotating devices and other equipments. |

| Controlling system | Structural feature: Communicating with WMS and ECS through OPC

agreement, PROFIBUS bus network, set up by Siemens S7-300

controller can operate all conveyors offline, doing conveying of

goods automatically. Please refer to the attached drawing for details of conveying system |

| WMS System | Hardwares of WMS System: Star network structure, network sever, RF server, computers for management and monitor, RF base station and RF terminal for in/out warehouse of goods. |

Application

1. Goods of large quantity and few kinds: food, beverage, chemical,

tobacco and other single kinds of items and of large quantity, etc.

2. Refrigeratory exercise: reduce low temperature working time,

improve work efficiency and operation safety.

3. Deadline management: articles on strict requirements batch,

require FIFO operations management warehouse

4. Increase storage capacity: the limited storage space, need to

maximize the use of space of warehouse.

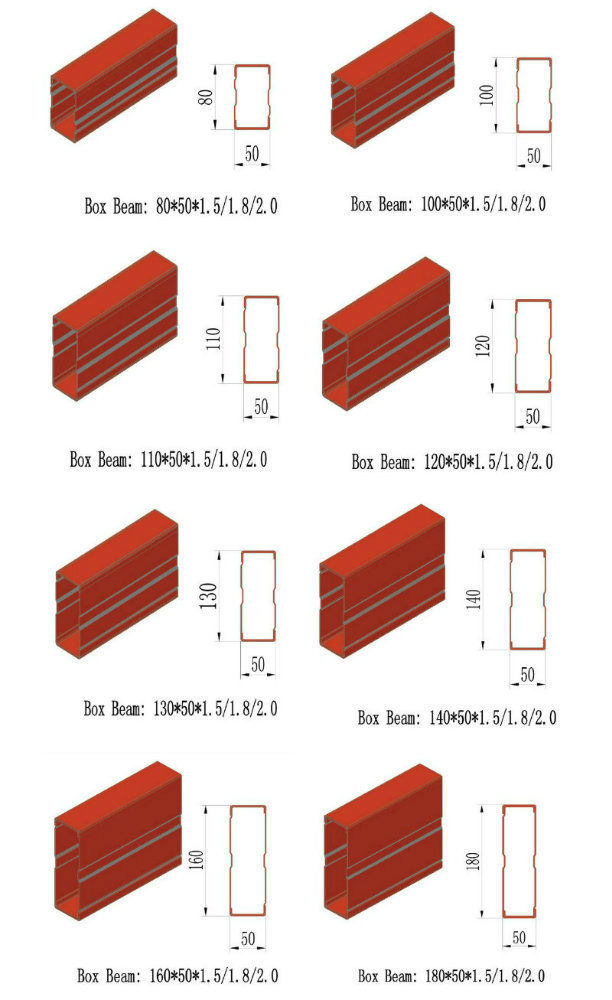

Beam

Please provide information for quick quotation

1. Pallet Size (Length*Width*Loading Height in mm)

2. Layout or Dimension (Length*Width*Net Height in mm) of your

warehouse

3. Rack Size (Length*Width*Depth in mm) if you are available or we

shall design for you

4. How many bays and levels if available

5. Loading Capacity(kg) of each level or each pallet

Production Of ASRS Rack

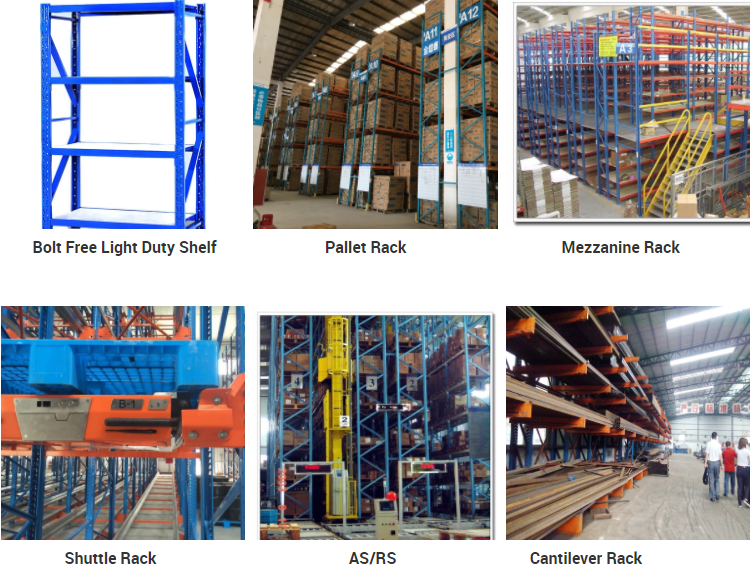

Main Products

Why Choose HUICHEN?

1. 17 years experience on manufacturing warehouse racking;

2. All types of racking comply with ISO9001, CE etc;

3. Have successfully done thousands of racking project;

4. Factory direct sale price, no cost for middle distributor.

Really important to choose a reliable warehouse racking supplier!!!

Service

Contact Us

Email: heidi@huichen.cn

Mobile: +86 176 6062 0398