Qingdao Huichen Logistics Technology Co.,Ltd |

|

Q235 Q345 Corrosion Protection Warehouse Radio Shuttle Racking

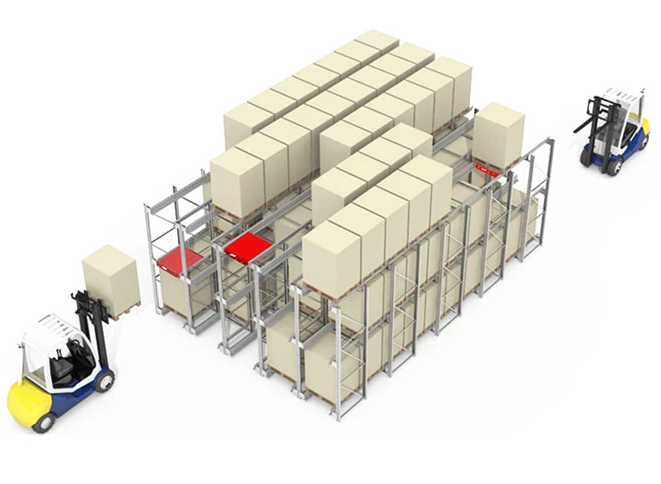

Radio shuttle racking storage systems is a new generation of high density storage racking system which max your storage utilization and working efficiency.

Radio Shuttle racking system is a high-density storage system composed of racking, radio shuttle and forklift;

Radio shuttle running on the special rail, and can be increased or decreased to raise and lower the pallet cargo, and return it to position.

The shuttle adopts radio remote control, and equipped with battery to provide power, and running forward and backward with four wheels.

The radio shuttle racking system is of high dense storage rack system with high investment cost.

It suitable for storage of large quantities and single species of goods for FIFO or FILO. But there is special requirement for the bottom surface of the pallet.

Space utilization rate can reach 80%.

Advantages:

Radio Shuttle Mover System could achieve 24 hours’ auto working to unmanned warehouse.

Unique technology, radio shuttle mover could be changed levels automatically.

Sophisticated equipment with advanced design concept, Fast Speed and accuracy positionings.

Radio shuttle carrier could charge the power battery of Radio Shuttle Cart during movement.

Movements in ternate directions are absolutely independent.

Powerful widenable system, could increase or reduce the quantities of radio shuttle carts and Radio Shuttle Carrier to solve warehouse storage working in peak time or low ebb time.

General introduction of Warehouse Bulk Storage Radio Pallet Shuttle Rack

| High Efficiency | Instead by smart cart to carry goods, there is no need for forklift to enter the lane, which improve the handling capacity and efficiency greatly. |

| Safety | Shuttle cart worked on the rail, so that there is no need for the forklift to enter the lane which improve the safety of processing. |

| Economic | Storage capacity improved in same space while the cost of storage equipment reduced obviously. |

| Operability | Wireless operation made the shuttle cart working by the order sending by the control center or the forklift driver. |

| Universality | Shuttle Racking can make the best use of space by using pallet in different specifications at the same time and adjusting the pallet accordingly. |

Core Functions:

1. Radio Shuttle Mover is one key vehicle for horizontal Movement in high Density warehouse storage system.

2. Function as radio shuttle carrier for Board the Radio Shuttle Cart and change aisles of the racks.

3. Working though single-unit equipment operation to achieve pallet to transport in/out the racks.

4. Auto operation by softwares for warehouse management and system controllment.

5. Storage Modes: FIFO(First In First Out), LIFO(Last In First Out)

Specification of the Radio Shuttle Cart:

| Specification | Rate loading | Depth | Width |

| HCCS-12-12-15 | 1500kg | 1200mm | 1200mm |

| HCCS-11-11-10 | 1000kg | 1100mm | 1100mm |

| HCCS-14-12-15 | 1500kg | 1400mm | 1200mm |

| HCCS-12-10-10 | 1000kg | 1300mm | 1000mm |

| HCCS-13-11-15 | 1500kg | 1300mm | 1100mm |

Here in after data sheet is based on the size of pallet 1200mm

| Serial | Tech data | Size(mm) |

| A | Pallet width | 1200 |

| B | Upright inside size | 1360 |

| C | Shuttle cart rail | 1010 |

| D | Upright size | 90/100/110/120 |

| E | Bottom height | 420 |

| F | Height | based on the fact |

| G | Min height between cargo and pallet | 375 |

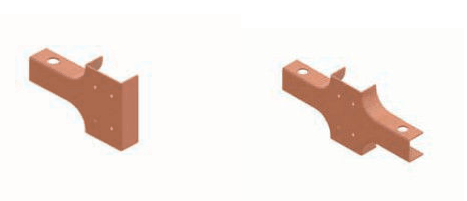

Upright & Bracket

Application:

Food, beverage, chemical, tobacco and other single species, large quantities and relatively single item product.

Date critical cargo such as fruit and food can also be stored.

Required information from customers for quick quote:

1, the AUTOCAD drawing or draft drawing of warehouse or racking.

2, the size of the warehous, length, height, and width.

3, how many layers of the racking?

4, your pallet size.

5, max weight of pallet with cargo on.

6, special color requirement.

Production Of Radio Shuttle Rack

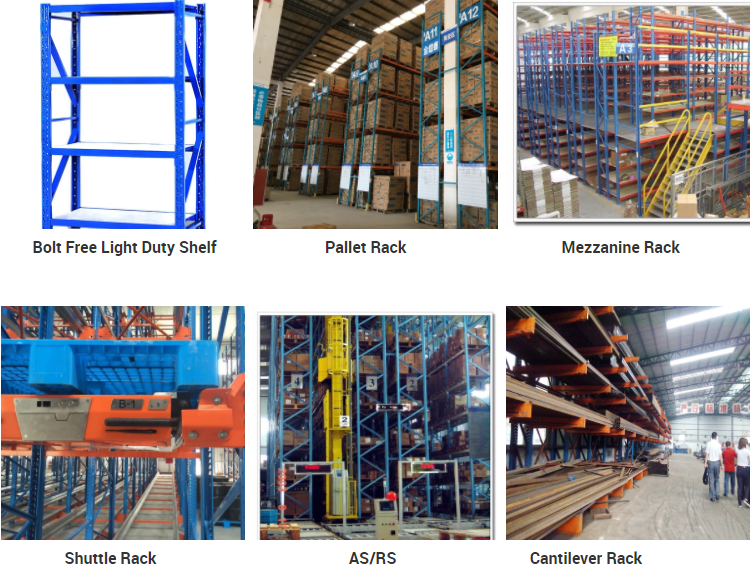

Main Products

Why Choose HUICHEN?

1. 17 years experience on manufacturing warehouse racking;

2. All types of racking comply with ISO9001, CE etc;

3. Have successfully done thousands of racking project;

4. Factory direct sale price, no cost for middle distributor.

Really important to choose a reliable warehouse racking supplier!!!

Service

Contact Us

Email: heidi@huichen.cn

Mobile: +86 176 6062 0398