Qunxingwang Mould Technology Co.,Ltd |

|

Customized Design Automotive Plastic Injection Molding

customized design automotive plastic parts /plastic automotive OEM

injection mould/plastic injection automotive products

Description:

| Surface treamment | Texturing,polished | ||||||||

| De-mold Type | Automatic eject | ||||||||

| Mold Base | LKM, | ||||||||

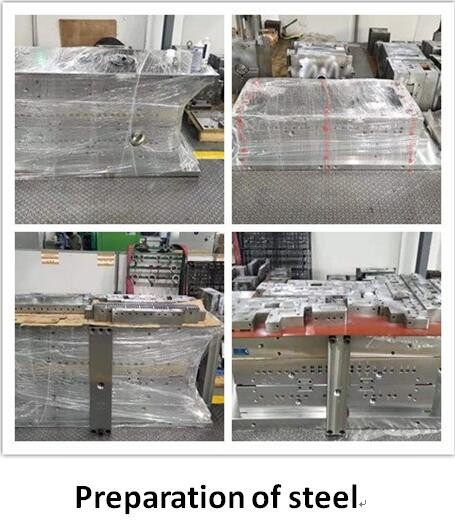

| Mold Material | 2344 | ||||||||

| Mould Cavity | 1 | ||||||||

| Sprue Gate | Hot runner, Cold runner , Submarine gate | ||||||||

| Design Software | UG,PROE,CAD | ||||||||

| Plastic Material | PP, PC, PS, PAG, POM, PE, PU, PVC, ABS, PMMA | ||||||||

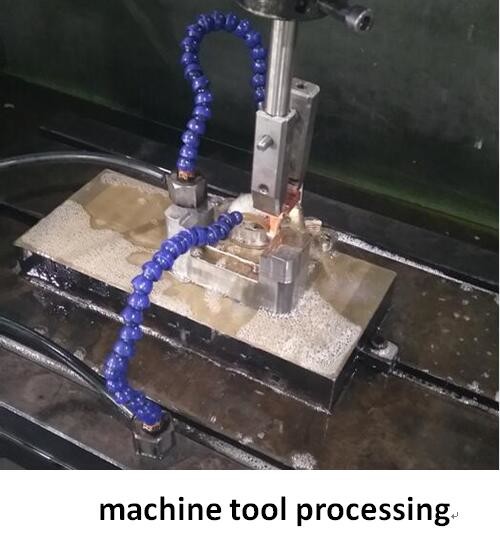

| Main processing equipment | CNC, EDM, Milling machine, Grinding machine, Injection machine | ||||||||

| Moild Life | 300000-1000000 shots | ||||||||

| Cavity/core steel | NAK80,S136,2316,2738,H13,S7,718H,2344 | ||||||||

| Steel hardness | HRC48-52 | ||||||||

| Cycle time | 40 seconds | ||||||||

| Design time | 3 days | ||||||||

| Specification | As your requirements | ||||||||

| OEM order | Greatly welcome | ||||||||

FAQ:

Q1. What kind of production service do you provide?

Mold making, die casting, CNC machining, stamping, plastic

injection, assembly, and surface treatment.

Q2. How about the lead time?

Mold: 4-5 weeks

Mass production: 4-5 weeks

Q3. How about your quality?

♦We have got ISO9001:2015 and IATF16949 certificates.

♦We will make the operation instruction once the sample is

approved.

♦We will 100% inspect the products before shipment.

♦Transactions can be through Alibaba's trade assurance.

Q4. How long should we take for a quotation?

After receiving detailed information(your 2D/3D drawings or samples), we will quote you within 2 days.

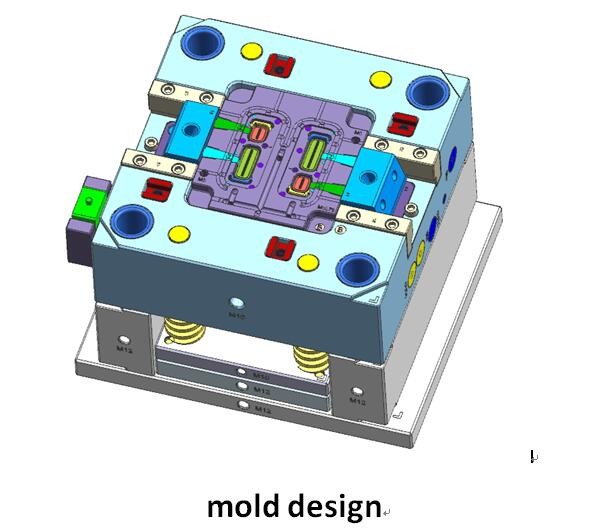

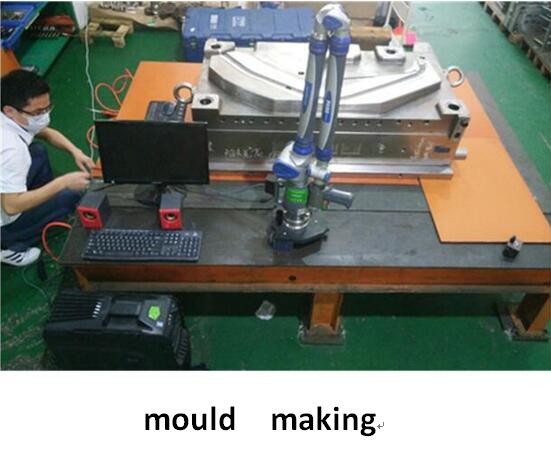

Detail image:

Production equipments:

Production processing:

.

.

1. the mould surface of cavity and core will be covered

with anti corrosive oil.

2. the guide pin and guide bushing will be covered with

butter.

3. the mould will be wrapped in plastic film.

4. the mould will be packed in customized wooden

case.

5. the wooden case will be strapped with metal bands.

6. some other spare parts will be put into the wooden case together

with mould, there are material certificate, mould data

CD, hot sprue , lifting bolt , ejector pin etc.

Advantages of our plastic injection mould :

We have a professional tooling design team with several years experience.

1. Various materials and short lead-time.

2. Good steel and long lifetime.

3. We can supply "one-stop" service with molds opening, injection,

painting, screen printing, assembly and nice after-sales service in

long term.

4. Full set of machines for mold making and injection molding.

5. OEM&ODM service available.

6. Mould's design based on tooling engineer from our company and

experienced with years in the industry.

7. Mould's steel as per customers' requests such as NAK80,

S1369(H),2738, 718, 738 and etc.

8. Final products' materials' optional: ABS, PP, PE, POM,

PA6(66)+GF, PC, PMMA, HIPS, GPPS and etc.

9. Products' color: As the customer's requirements, any color is

possible, if they could provide us the color card schedule.

10. Service scope: Open mould, Injection, CNC processing,EDM

processing ,coating, screen printing, assembly for finished

products and so on.

11. Good cost and high effeciency of delivery.