Guangzhou Kinte Electric Industrial Co., LTD |

|

Verified Suppliers

|

|

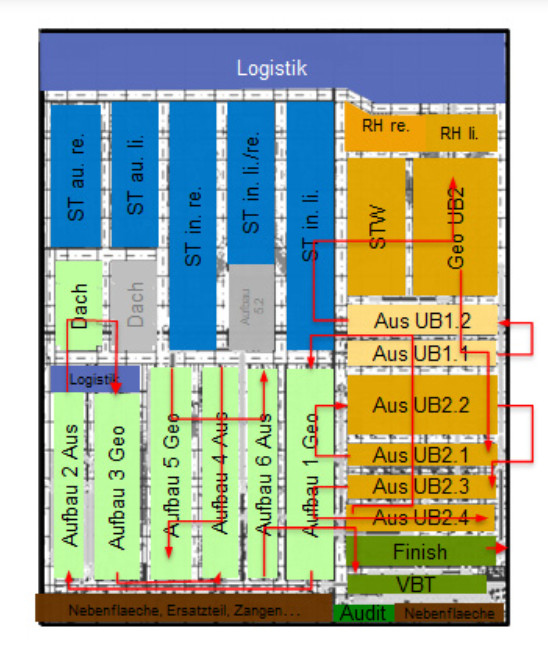

60JPH EV Plant

| Area | Two floors, 90000m2 |

| Scope | Main Line, Body Side |

| Models | 4+2(reserve) |

| Cycle Time | 60JPH(51s) |

| OEE | 85% |

| Automation Rate | 95%以上 above 95% |

| Robots | 850 |

| Main Process | Spot welding, Gluing, CMT Brazing, AutomatedScrewing,Laser Brazing, Roller hemming.Automated Riveting |

Flexible production line

The flexible welding line means that the same production line in the same place can satisfy the production of multiple vehicle types at the same time. Every time a new model is developed, it only needs to add some special equipment, modify the pre-set general equipment, and debug all kinds of vehicles. a shared program.

Integrated Fixtures for Welding Production Line

The main production methods of the welding workshop include: spot welding, CO2 shielded welding, laser welding and pressure forming. The corresponding fixtures are all in the form of assembly welding fixtures, integrating electrical and control technology, and maximizing the advantages of flexible production lines. The welded fixture set is a combination of joint surface positioning, point positioning, positioning pin positioning and clamping positioning. This article mainly introduces the main line synthesis machine, the side wall trolley, the movable rotary table of the suitcase, etc.

Fixture switching for flexible production

The key to the realization of a flexible production line is that the same station can realize the switching of fixtures for different models. In the process of body manufacturing, according to different switching methods, it can be divided into overall switching, partial switching and full servo switching.

Overall switching, the production station has multiple sets of production fixtures, which means that during the production process, a complete set of production fixtures is switched to the production station by means of rotation or movement. There are mainly rotary table switching, movable rotary table switching, and trolley switching.