Guangzhou Ribo Plastic Packing Machinery Co.,Ltd. |

|

PET Water Bottle , Beverage Drinks Bottle , Edible Oil Bottle Automatic Blow Moulding Machine

Introduction of R series machine

I. Summary

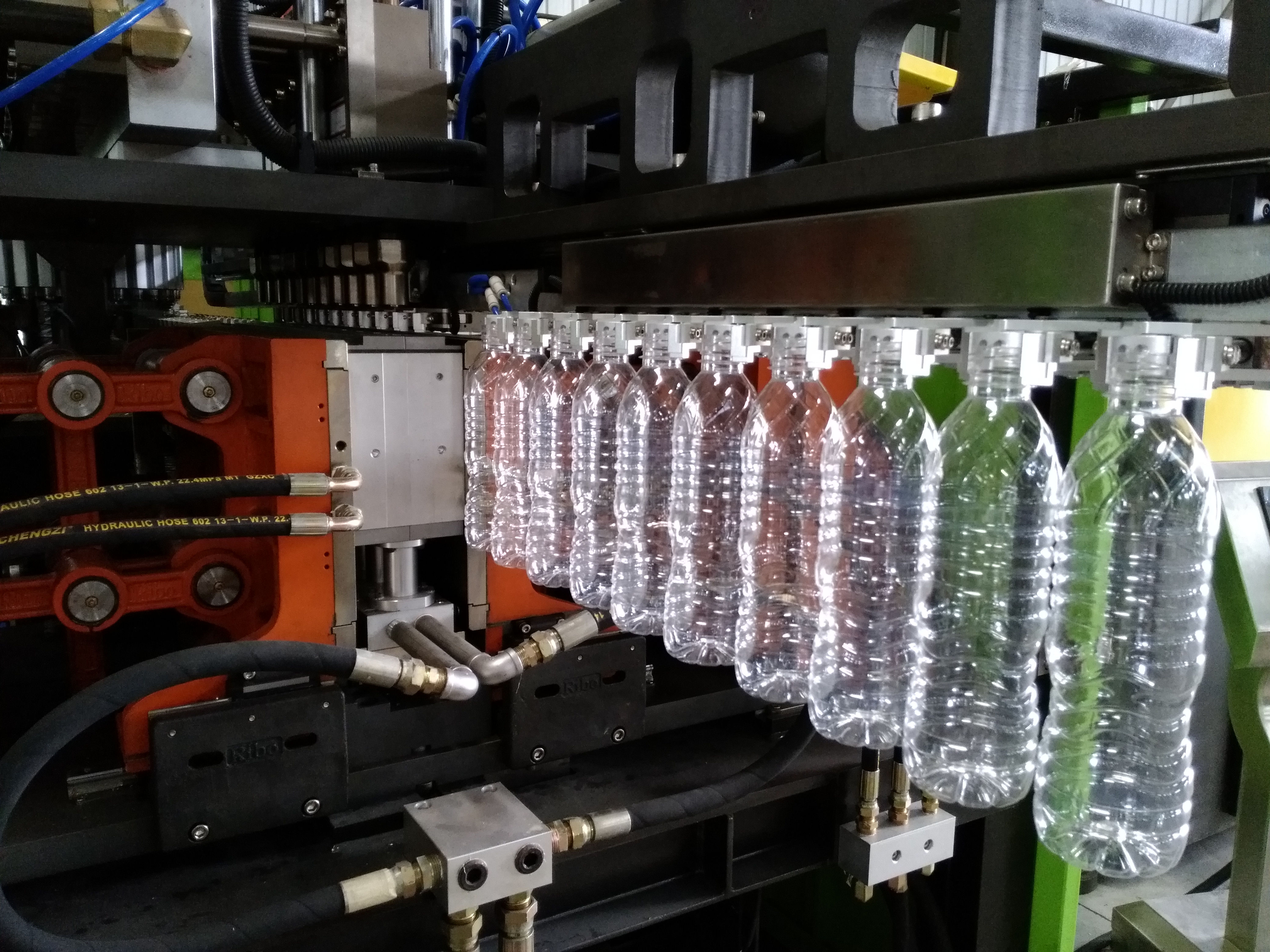

R series linear full electric PET bottle blow molding machine is a high speed automatic PET blower designed and developed with the most advanced bottle blowing technology at present, the advantages of which can be described as speedy, stable, simple, general purposed and environmental safe. It is mainly applicable in blow molding PET containers for water, beverage, juice, etc. The machine yields abundantly with high efficiency. The capacity of each cavity has been increased to 2750~2000bph when the bottle size is equal to or less than 0.55L respectively, which can meet the high-end customer's requirements. Equipped with preform auto loading system, the machine works fully automatically with consistent performance and high speed, without any operator's interference during the whole processes. Accordingly, chance of contamination can be reduced manifestly, which assures the quality of products.

II. Technology Development

Application of servo PLC system:

Adopted Omron motion controller system (integration module type), using the PTO (servo positioning module) system for high-speed positioning, proximity sensors search the orbital target location, sending high-speed signals to the servo system. The position of the track is detected online by the high precision rotary encoder built-in the servo motor, sending back informations to the control system, finally, high-speed positioning is carried out by positioning module.

Application of the servo motor

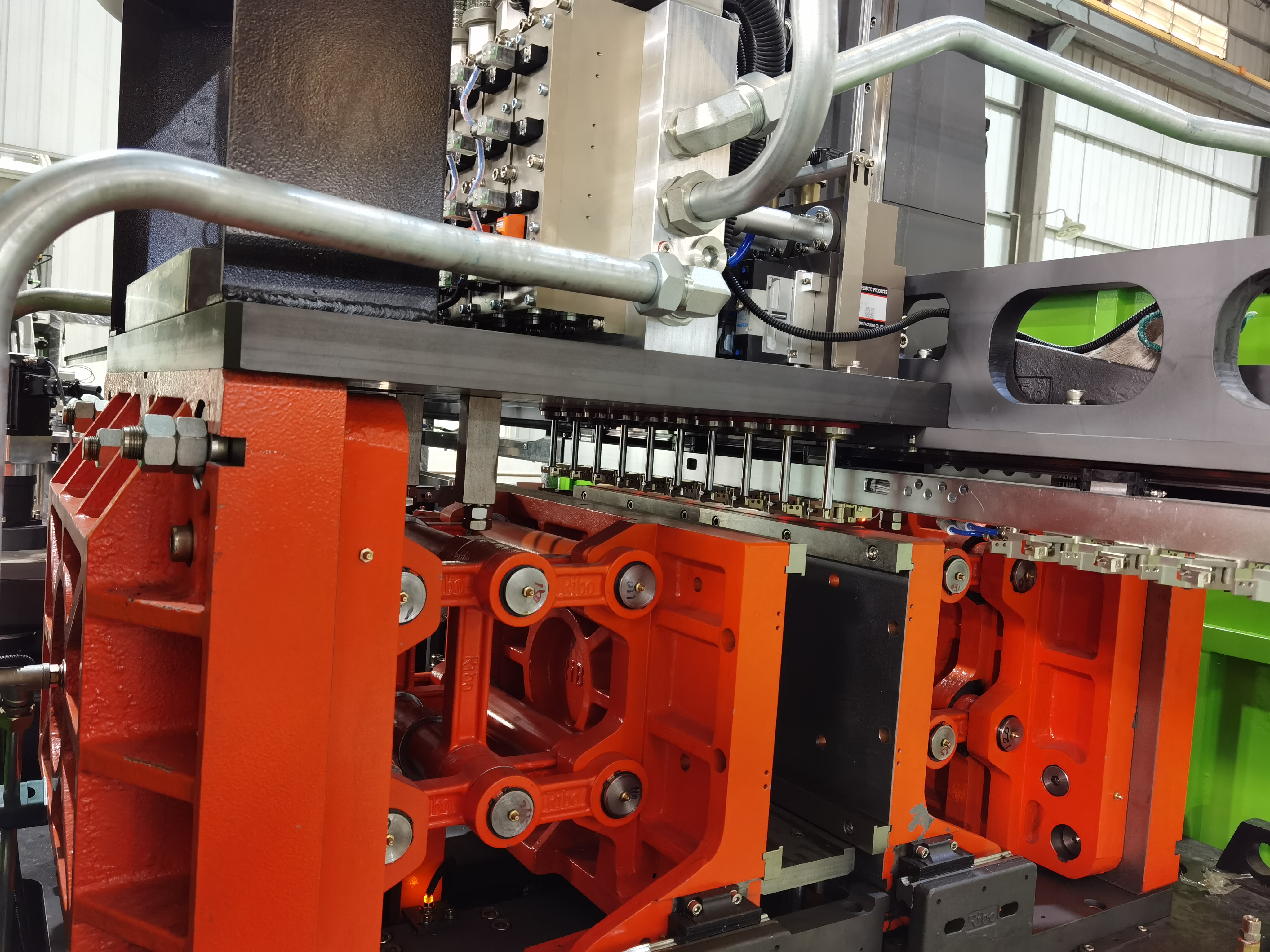

The mould movement mechanism: Adopted the servo motor connect the gear box, synchronical transmission system is adopted to fulfill the reciprocating up and down motion of the two hinge mechanisms on both sides of the mold hauled by two linkage rods respectively. In this way, the two mold holding plates in the middle move oppositely or towards each other, which is generally known as mold opening and closing. The hauling wheel driven by the servo motor makes clockwise rounds continuously, reducing the power impact and the wearing, makes the mould clamping more smoothly. Each round leads to a complete cycle of mold holding plates movement------open and close. Also the high pressure air supercharged mold locking mechanism is applied which buffs the impact between mold plates and effectively protects molds. Besides, it does help to reduce the visibility of parting lines on finished bottles. The servo motor driven mold movement mechanism is designed and created upon rigid engineering simulation analysis, which ensures that the series of the mould motions are simple, accurate, consistent and speedy, making cycle time 0.2~0.4 seconds.

The preform feeding and preform heating holders transfer mechanism: The preform feeding star wheel and preform heating holders transfer mechanism are driven by the servo motor synchronous belt linkage type drive step. For preform rotary heating system, the preform heating holders is controlled by variable frequency motor, preforms (preform neck is upwards) are 360 degree uninterruptedly rotary heating,38mm Preform heating pitch, more preforms are uninterruptedly heated within the same distance, which improves the efficiency and energy saving above 50%. The same servo motor is used to synchronously operate on a slide track for rotating high-speed stepping positioning to simplify the structure, which makes the stepping track speedy and stable, shorten the production cycle time and greatly improve the production efficiency.

The perform after heated / variable pitch mechanism: This mechanisam is adopted the servo motor to connect the screw directly, the screw turns around, the pitch was changed from 38mm to 98mm directly, ensure high speed and accurate perform handling between the two mechanism.

★At the variable part, adopted completely independent research and development of super hard alloy screw separation, surface 2mm Rockwell hardness can reach 68 degrees or more, and the screw smooth degree, wear-resistant degree in the industry is absolutely leading, the design service life can reach more than 15 years.

Preform transfer system with the grippers and bottle out-feed mechanism: Heated preforms delivering into the blow mould and the finished bottles out-feed driven by the same servo motor & the synchronous belt, to ensure the high speed and accurate for these two motions.

The stretching mechanism (down stretching): the stretching rods are driven by a servo motor all at once, which ensures the synchronicity of the motion of the rods and makes it easier to do adjustment prior to production. (After interchanging the blow mould, makes it much easier to adjust the height of stretching rods, just need to input the datas on the touch screen, instead of doing the adjustment by manual.)

Application of thermostatic heating system:

The modularized control system is used in the thermostatic flask blank heating oven, which use infrared lamps and reflector for heating preform. After setting the temperature value, the equipment can automatically adjust the output voltage according to the rate without being affected by voltage fluctuation and environmental temperature change. At the same time, it is also cooled by circulating air controlled by frequency converter, which can effectively guarantee the internal heating temperature and constant temperature of the heating ovens, and make the surface of each preform and its internal temperature uniformly heated. Moreover, the bottle rotates 360 degrees in the heating ovens, so that each side of the preform can be heated evenly, which improves the yield of blown bottle and the adaptability range of the thick-walled preforms.

The application of the full closed-loop voltage regulator in preform heating system:

The temperature of the heating ovens are controlled by the full closed-loop voltage regulator (with feedback) which independently developed by RiBo company. The controller detects and adjusts the output voltage (set value) at the scanning frequency of 100 times per second, so as to achieve the effect of evenly voltage output and solve the problem of unstable heating effect caused by the heat fluctuation of heating element (lamps) due to the voltage fluctuation of the power supply. In addition, the closed-loop control system interacts and cooperates with the original heating ovens’ constant temperature control system, greatly improving the heating temperature fluctuation caused by environmental temperature change. By application of the above technology in the bottle blowing machine, the heating uniformity and stability of each preform tend to be completely consistent, which finally ensures the stability and uniformity of the bottle blowing effect of each cavity. This closed-loop unit has further improved the overall performance of the bottle blowing equipment.

The machine is equipped with the preform temperature detection at the end of the last heating oven, if the preform temperature does not reach the blowing temperature, the preforms going into the blow mould but no blowing, saving the air.

III. Performance and Advantages

i.The man-machine interface is easy to operate. Everything is computerized, including temperature adjustment and preform distribution.

ii.Independent movable operation pannel, make the operation more convenient and flexible.

iii.Preform unscrambling, loading, bottle handling and ordering are all operated by stainless steel manipulator automatically without a second contamination.

iv.During the process of the automatic embryo preform feeding system, each preform channel has photoelectric detection, control the action of the upper motor and the parting cylinder, ensure the uniform distribution of the preform in each embryo channel, and have the function of alarming the material shortage.

v. The circulating chilling water system as well as the fan with converter controlled can protect the bottle neck against deformation when the preform is being heated.

vi. The homothermal heater adopts auto reflection and closed loop adjusting system which have the power supplied constantly in proportion, not affected by the fluctuation of voltage. The conveying chain is short pitched and paratactic, which helps to realize slow heating and low power consumption. As a result, the preform can be heated evenly and easy to blow.

vii. The positioned installation of molds makes it possible to change molds easily within one hour,the operator only need to stand on the ground can finish this job, no need to stand on the machine frame,the safety for person is much higher.

viii. All the critical parts we use for the machines, such as the electrical, pneumatic components, servo motor, etc, are famous branded parts imported from Japan, USA and Europe,which ensures the stability and long life of our equipments.

ix.The high pressure blowing valve is equipped with the device of converting to low pressure air, which can ensure the normal conversion without low pressure air. Machine is equipped with the high pressure air recovery device, in the process of bottle blowing production, the high pressure air can be recoveried and used for the cylinders/ pre-blow.

IV. Easy Maintenance

Omron servo controller system (motion controller, modular) is connected with the machine via particular communicating cables.The user can manage all the actions of the machine through the motion controller. Once the machine has a fault, the man-machine interface will provide warning signals and fault diagnosis report to the operator, the operator can quickly find the cause of the fault and troubleshoot as soon as possible through the fault display.

★ If the bottle is blocked/full in the air conveyor, the function of automatic stop feeding preforms can be set in the program through photoelectric detection.

★ If the equipment after blowing machine stops working for too long time, the heating lamp can be set with the function of automatically reducing temperature, saving electricity consumption and avoid the excessive temperature in the heating seat.(Temperature setting is set in touch screen)

★The position of the screw variable pitch preform transfer mechanism is equipped with photoelectric detection and protection device. When the transfer of preform is not in place, the blowing machine will stop automatically to effectively protect the components of the variable pitch system.

V. Safety

The reciprocating parts of the bottle blowing machine are equipped with protective devices and warning signs.

i. The safety of operators

The machine is totally enclosed with perfect reliable safety door and also equipped with aluminum antislip plate on the principal surface, which can assure operators' safety to the largest degree.

ii. The safety of the machine

The multiple points detection technique is adopted to ensure the safe running of the positioning system, the clamping system and the stretching system to the largest degree.

Technical Parameter

| Items | Unit | Model | |

| RiBo-8CR600 | |||

| Molding Spec. | Preform Pitch | mm | 76 |

| Preform Heating Pitch | mm | 38 | |

| No.of Cav. | cav. | 8 | |

| Container Spec. | Max.Container Volume | L | 0.7 |

| Neck Diameter Range | mm | 18~30 | |

| Max.Containr Diameter | mm | 70 | |

| Max.Containr Height | mm | 240 | |

| ※※Theoretical Output | bph | 19000~16000 | |

| Power Spec. | Rated Power | KW | 123 |

| Power Consumption | KW | 40~50 | |

| Compressor Spec. | Blowing Pressure | Mpa | 2.5~3.2 |

| Air Consuming | m3/min | 8 | |

| Main Machine Spec. | Size | mm | 6758*3331*3200 |

| Weight | Kg | 8500 | |

| *Due to continuous technical development specification would be improved without prior notice. | |||

| *Special designs correspond to customers needs. | |||