NINGBO NIDE MECHANICAL EQUIPMENT CO.,LTD |

|

Verified Suppliers

|

|

Automatic electric motor external rotor coil winding machine with 2

stations needle winder

(1) Automatic external rotor winding machine Technical data :

| Product name: | Automatic external rotor needle winding machine |

| BLDC rotor O.D.: | 80-200mm |

| BLDC rotor height: | 18-35mm |

| Wire diameter: | 0.2-1.3mm |

| Winding method: | needle winding |

| Power supply: | 220V,50/60 Hz |

| Parallel winding wire number: | 1-8 |

| Machine weight: | about 700KG |

| Dimension: | 1300*800*1500mm |

(2) Automatic external rotor winding machine Application:

The automatic external rotor winding machine is used for BLDC motor

manufacturing ,such as air heaters motor, heat pumps motor,

condensers motor, cooling units motor, evaporators motor,

electronic equipment motor for air or heat dissipation, etc.

(3) Automatic external rotor winding machine Function and

Characteristics:

1. The automatic motor external rotor winding machine adopts needle

coil winding technology, is sutiable for multi-pole BLDC armature

coil winding. Manual loading and unloading, automatic clamping,

winding and shearing.

2. The frame adopts thickened 4080 aluminum profile, and the table

plate adopts cast iron to absorb vibration, even when winding at

high speed, the vibration is very small.

3. Tooling and fixture parts adopt downward positioning mode,

stable positioning and reliable tightening.

4. Wire clamping and wire cutting, line part structure compact,

wire clamping and wire cutting is completed at one time;

5. Different stator and winding parameters can be quickly switched

through the HMI to adapt to different stator requirements.

6. Quick change-overof tooling;(20 minutes with proficiency)

7. Full aluminum alloy protection

8. PLC control, fault display

9. The wire tightness is moderate, no injury, no breakage, ect.

10. The salt test of the product is carried out within 10 mA in one

minute.

11. Equipment safety index: accord with CE standard.

12. Efficiency: 120 rev / min.

13. Beat: 5 minutes / BLDC rotor.

14. Noise: 60-70 decibels or less.

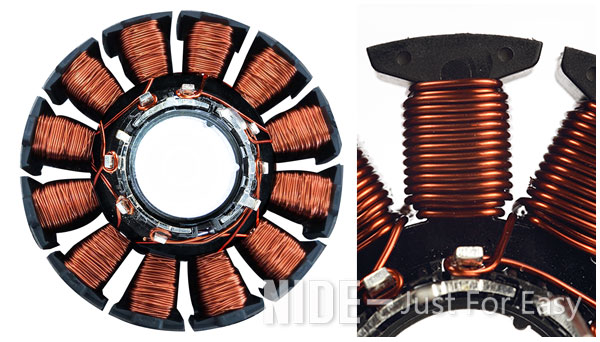

(4) Automatic external rotor picture display: