Anhui Aoxuan Heavy Industry Machine Co., Ltd. |

|

Verified Suppliers

|

|

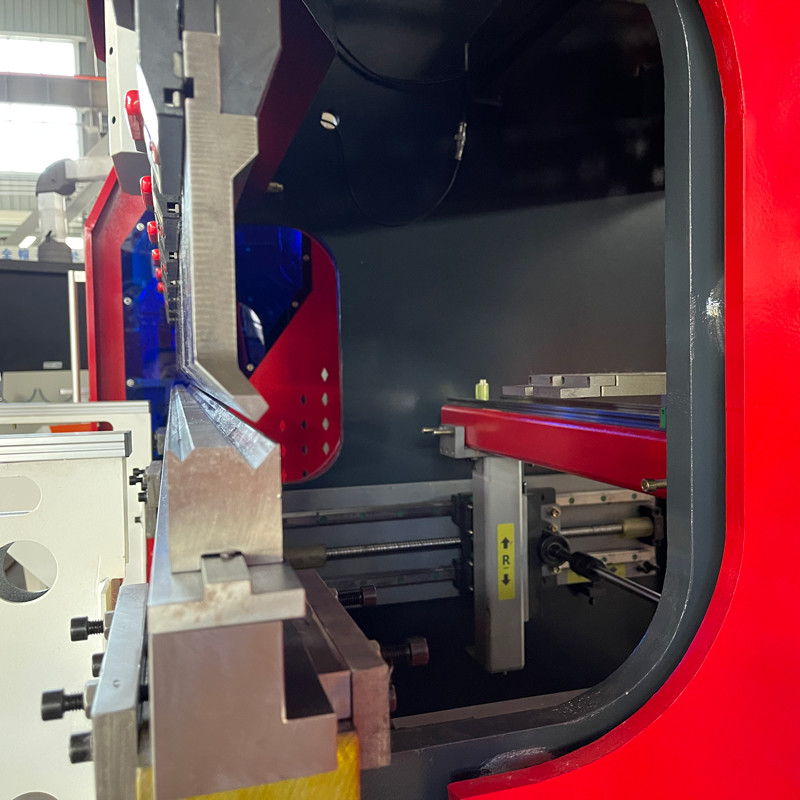

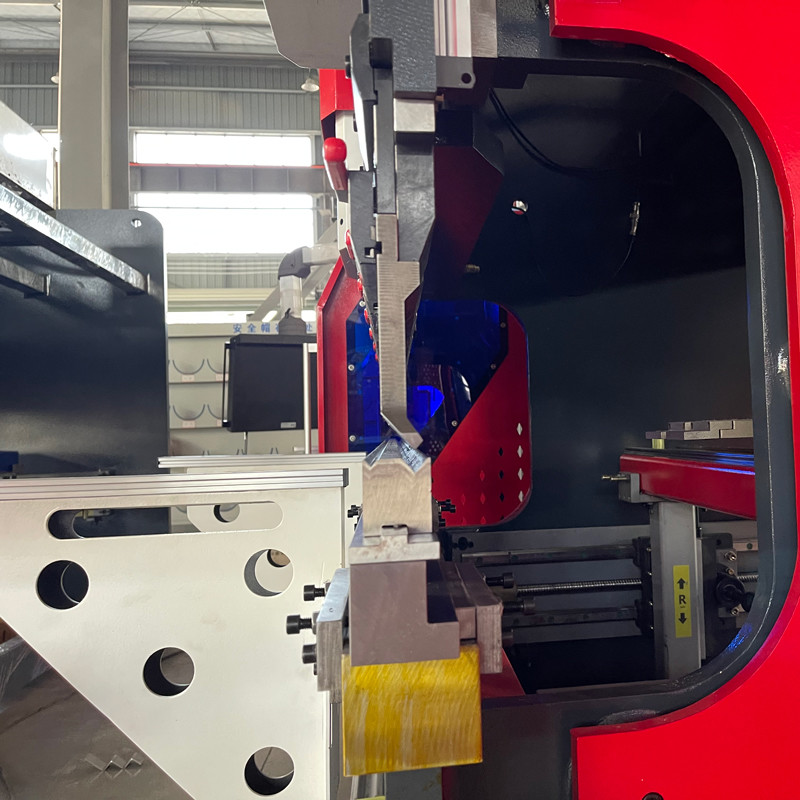

Hydraulic CNC Press Brake Electro-Hydraulic 63T Sheet Metal Bending Chinese Stable Controller 4 Axis

15.6-inch full-color touch screen

Simple and easy to understand operation interface

1. Support angle programming and depth programming switching

2. Support mold library product library settings

3. The opening height can be freely set for each working step.

4. The shifting point position can be freely controlled

5. Standard Y1, Y2, R-axis multi-axis expansion

6. Support mechanical compensation workbench control

7. Support large arc automatic generation program

8. Supports top dead center, bottom dead center, foot release,

delay and other step changing options, effectively improving

processing efficiency

9. Support electromagnet simple bridge

10. Supports fully automatic pneumatic supporting bridge function

11. Support automatic bending, realize unmanned bending control,

support up to 25 steps of automatic bending

12. Support valve group configuration functions, fast down, slow

down, return, unloading action and valve action time control

13. 200 product libraries with 25 working steps, each product

library name can be customized in Chinese and English, and the

large arc supports 99 working steps.

| Technical Parameter | Description |

|---|---|

| Voltage | 380V/220V optional |

| Overall Dimensions | 2850*1800*2300mm |

| Distance between housings | 1960mm |

| Net Weight | 3000KG |

| Color | Customized |

| Main Motor Power | 5.5KW |

| Postioning Accuracy | ±0.03mm/m |

| Max. Opening Height | 345mm |

| Controller System | HK58T controller system, China |

Aoxuanzg Press Brake is a high-quality and reliable machine used in metalworking industries for bending and shaping sheet metal. Its compact structure and advanced technology make it a popular choice for various applications.

This Press Brake from Aoxuanzg offers customizable services to meet your specific needs. With a compact structure and AC motor, it provides high precision and easy operation. Its stable performance and high efficiency make it a reliable choice for your bending needs.

The Press Brake will be carefully packaged to ensure safe delivery to our customers. It will be packed in a sturdy wooden crate to protect it from any damage during shipping.

With our careful packaging and reliable shipping, customers can be assured that their Press Brake will arrive in perfect condition and on time.

1. Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of

Analysis/Conformance: Insurance: Origin, and other export documents

where required.

2. What is the average lead time?

For samples the lead time is about 7 days. For mass production the

lead time is 20-30 days after receiving the deposit payment.

The lead times become effective when (1) we have received your

deposit and (2) we have your final approval for your products. If

our lead times do not work with your deadline, please go over your

requirements with your sale. In all cases we will try to

accommodate your needs. In most cases we are able to do so.